Ultrasonic Stencil and PCB Cleaner of SMT Screen Printing Template Solder Paste Defluxing Steel Mesh Ultrasound Cleaning Machine

Ultrasonic Stencil and PCB Cleaner

Ultrasonic Stencil and PCB Cleaner enable to clean any type of solder paste,red adhesive glue from any fine pitch stencil, at the same time, its low power density and high ultrasonic frequency are safe for cleaning misprinted PCBs and pallets, its low temperature cleaning conserves energy and protects stencils from heat distortion and adhesive failure

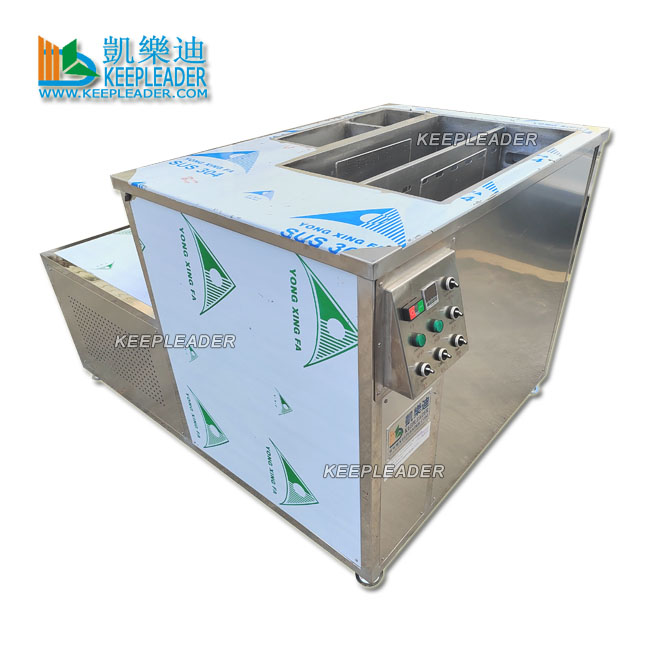

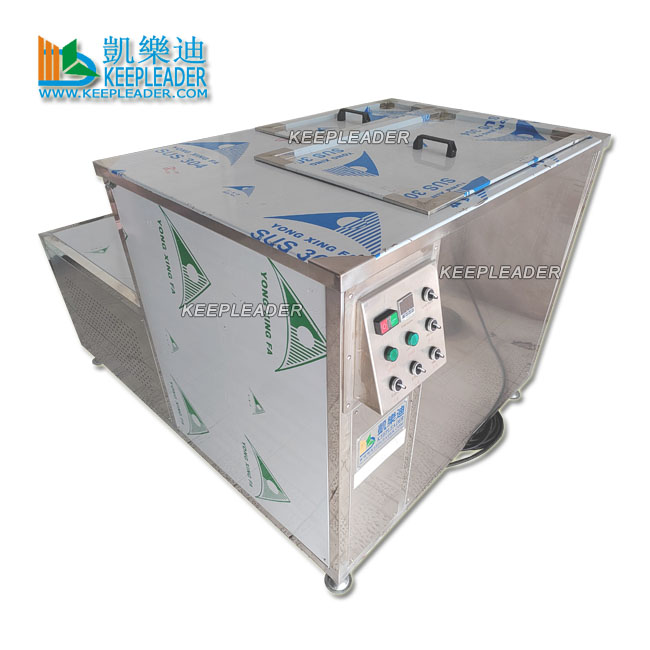

Machine Description

Ultrasonic Stencil and PCB Cleaner

Ultrasonic Stencil and PCB Cleaner

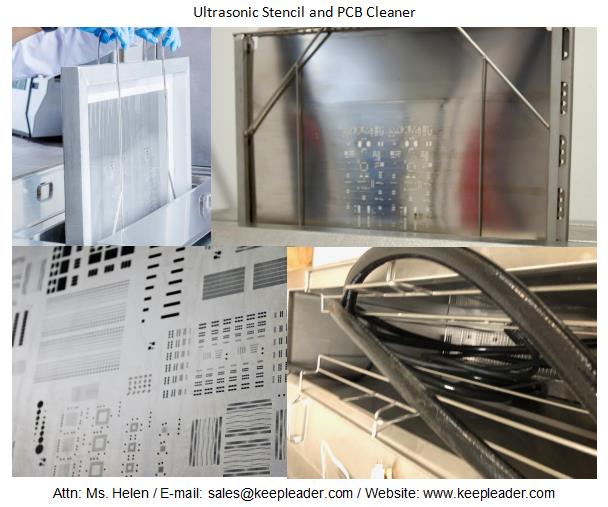

Application

Ultrasonic Stencil and PCB Cleaner utilizes precisely controlled ultrasound waves to eradicate nu-re-flowed solder paste, red glue and uncured adhesives from stencils, screens, misprints, pallet and squeegee, the ultrasonic energy under intensity control is gentle and even and will not damage delicate parts, but it is highly effective in the removal of even dried pastes on the fine-pitch stencils, this Ultrasonic Stencil and PCB Cleaner is composed of two chambers, a ultrasonic agitation tank and immersion rinsing tank, in addition, independent filtering circulation is integrated, hence, it is a closed-loop circulation cleaner to eliminate discharge and to prolong the wash solution life and avoid cross-contamination, ultrasonic agitation is performed by intelligent ultrasonic generators of 40khz in a liquid cleaning medium, this process called cavitation forms bubbles in the liquid that reach even the tiny apertures of the stencils, the bubbling action provides with mechanical force to separate contaminants from the stencil, higher frequency can result in better cleaning but the exposure time to moisture increases which could harm the stencil adhesive bonds, it is therefore a standard practice to use sweep feature to gain the optimal performance, stainless steel made of Ultrasonic Stencil and PCB Cleaner can efficiently damper the energy’s deterioration during transmission, and resist on detergent corrosion, ultrasonic mechanical agitation participates proper detergent is a practical approved approach in versatile stencils restoration after printing process, that being regarded as reliability, durability, compatibility and cost-efficiency in SMT field of stencil cleaning procedures

Parameter

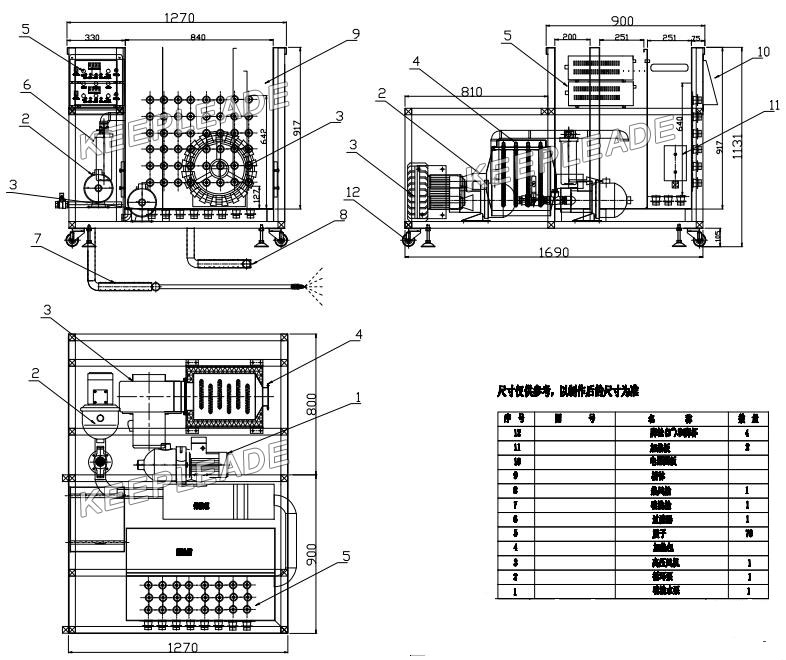

Name | |

Model | KLE-1072S |

Ultrasonic Power | 3600w |

Heating Power | 2000w |

Circulation Pump | 500w |

Ultrasonic Frequency | 40khz |

Qty of Cleaning Tank | Dual tanks |

Inner size of Ultrasonic Chamber | 840*250*840mm |

Inner size of Rinsing Chamber | 840*250*840mm |

Inner Size of Filter circulation Tank | 840*350*840mm |

Filtering Capability | 20um |

Application | Solder Paste and Uncured Adhesive Removal |

Stencil Size | 738*738mm |

Power Source | 110v/220v,50hz/60hz |

Cleaning and Rinsing Time | Approx. 5min./cycle*3 |

Construction | Welded Tube Steel Frame |

Material | Stainless Steel |

Finish | Stainless steel Matrix, or Powder-Coating Epoxy |

Vibrators Position | Mounted on the beneath and side of tank |

Control | Digital Timer, Temperature Control |

Packaging Dimension | 1.9*1.5*1.3m |

Groess Weight | 388kgs |

Salient Character

Stainless steel construction to improve longevity and resist detergent corrosion

Low profile is coupled with stencil rack for easy loading and unloading

Gratification for versatile stencil, and effective to decontaminate all types of solder pastes

Digital Temperature control, ultrasonic intensity and intermittent time of ultrasonic agitation

Safe 31 watts per liter power ration for optimal safety control

Independent filtering circulation system effectively filters out loosed particles

Filtering cores made of stainless steel are precision etched or laser cut for residue filtering

In options of Hand-held rinsing wand, hot air drying gun and auto lift and transmission

Liquid level detector to monitor liquid ratio to avoid liquid absence or insufficiency

Overflow integrates pumping circulation to complete closed-loop filtering circulation

Detailed Images

Ultrasonic Stencil and PCB Cleaner utilizes precisely controlled ultrasonic waves to travel into the aqueous tank, that enable the detergent fluid contract and expand in generating cavity performance in yielding implosive tiny bubbles, these blasting voids enable to remove UN-reflowed solder paste and uncured adhesives from stencils, screens and misprints, the ultrasonic energy is gentle and will not damage delicate stencils fine pitch apertures, but it is highly effective in the removal of every dried pastes on fine pitch stencils, water low level protective device shouts down the machine if the water level drops below the minimum requirements to avoid damage, keepleader’s Ultrasonic Stencil and PCB Cleaner has dual ultrasonic tanks, a washing tank, and a rinse tanks, both of them have ultrasonic energy and heat,high pressure spraying wand can play a rough cleaning or ultimate rinsing process in flexibility, after washing, the hot air drying hose complete quick drying precede next procedures, furthermore, Ultrasonic Stencil and PCB Cleaner accepts bespoke construction in its dimension and configuration, filter circulation reservoir can be integrated to avoid cross contamination and reduce the water consumption, its maximum loading size make to order to gratify end-user’s prominent application

Machine Uses

Ultrasonic Stencil and PCB Cleaner employs ultrasonic energy with aqueous detergent solution that cleans at low temperature 43 Celsius degree, would be considered to be the ideal process combination for cleaning fine-pitch SMT Screens and stencils, detergents are wetting agents that can be formulated to attach specific contaminants given specific cleaning parameters such as low temperature and type of cleaning agitation, Ultrasonic Stencil and PCB Cleaner is the best possible cleaning agitation to deliver the cleaning solution, and to scrub the fine and ultra fine-pitch apertures, it causes the least possible trauma to the etched images, the resulting liquid waste can be easily filtered in an existing filtration system

Configuration Illustration

Ultrasonic Stencil and PCB Cleaner is able to clean any type of solder paste from any fine pitch stencil at the same time its low power density is safe for cleaning of misprinted PCBs in SMT application, its low temperature cleaning conserves energy and protects stencils from heat distortion and adhesive failure

Packaging

Ultrasonic Stencil and PCB Cleaner is packaged in plywood case for safe transportation

Contact Us

KEEPLEADER is a leading provider of Ultrasonic Stencil and PCB Cleaner for SMT and semiconductor industry, we have been committed to delivery superior performance, high production efficiency, and cost effectiveness to our customers, and the market, unlocking unlimited possibilities for the SMT and semiconductor industry, over the years, we have collaborated closely with both existing and new customers to develop Ultrasonic Stencil and PCB Cleaner that meets their evolving needs, our dedication to innovation has enable us to stay ahead of the curve and provide cutting-edge solutions that drive progress in the industry, we strive to deliver exceptional service and support that exceeds expectations, we are ready for your initiation, ensure that our experienced team can work out a reliable solution at affordable price for you stencil cleaning process

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2025 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader