Rotary Friction Plastic Welding Machine of Round_Circular_Cylindrical Nylon_PP Cup_Mug_Filter Assembling Spin Frictional Welder

Rotary Friction Plastic Welding Machine

Rotary Friction Plastic Welding Machine has simple concept in fusion, one component rotates rapidly relative to its stationary counterpart under axial pressure, the heat of friction softens the interface, and the pressure of the forging squeezes out contaminants and forms a solid bond when rotation stops, rotating, non-consumable tools are inserted along the join lines between parts, friction heat the material, causing it to plasticize without melting, the tool’s pins mechanical stir the softened material, creating a dense, void free weld

Machine Description

Rotary Friction Plastic Welding Machine

01: Application

Rotary Friction Plastic Welding Machine is a welding technique that uses heat generated by rotational friction at the joint line to weld thermoplastic parts, particularly for PP,PE,PET,Nylon and other semi-crystalline material, which is not suitable for ultrasonic vibration bonding, in this technique, friction is used to heat the parts to be welded, it applies axis symmetric pressure as it rotates one part against the other stationary part

Rotary Friction Plastic Welding Machine has obvious advantages, such as: ability to weld parts with circular joint that are not easily welded by ultrasonic vibration welder; relatively fast cycle times when compared with other approaches; compatible with most thermoplastic, typically for PP,PE,PET,Nylon and other semi-crystalline material;Ideal for welding of Nylon, GS filled, PP and PE materials; ability to weld several dissimilar materials; no consumable, fumes or emissions during fusion, because of its plasticized solidification in sold-status;high strength, hermetic welds are typical in aesthetic appearance; heat confined to weld interface; easily automated; low cost, quick change tooling kits; low maintenance and low power consumption

Rotary Friction Plastic Welding Machine has wider welding scenarios, likely automotive: Fuel system filtration, air duct, filter bowls and oil fill tube components; appliance: water valves, refrigeration water filtration, and toilet components; irrigation system: sprinklers components; pool and spa: filtration components; beverage: dispensing, beverage cups; medical: syringes

02: Attributes

Name | |

Model | KLP-1500 |

Motor Power | 2000W |

Electric Connection | 220V,50HZ |

Motor Torque | 3,8 Nm max |

Spindle Diameter | Within 200mm |

Motor Revolution | 3000r/min (60s*linear speed*Diameter*π) |

Precision | +/-0.5degree |

Velocity | +10m/s |

Linear Speed | 0.2~2m/s |

Absorption | 4A |

Optimum Welding Pressure | 64.8kpa (64.5~65.2kpa) |

Optimum Spin Time | 1.0s |

Optimum Initiate Instance | 9mm |

Optimum Rotational Velocity | 700~2500rpm |

Head Decent Cylinder | 63mm*75mm |

Stroke | 100mm Max |

Thrust Pressure | 180 Kg. max. |

Productivity | 10-15pcs/min |

Dimension | L750mm*W800 mm*H1950mm |

Gross Weight | 380kgs |

Packaging Volume | 1.8CMB |

03: Advantages

Rotary Friction Plastic Welding Machine offers numerous advantages over traditional welding processes, such as following elements

Fast weld time: with typical cycle times in the range of within 1 seconds, plastic spin friction welder enables efficient production processes

Versatility in part size: plastic spin friction welder can accommodate a wide range of assembly sizes, from small automotive components to large laundry machine drums

Compatibility with various thermoplastics: please spin friction welder is suitable for user with most thermoplastics, including materials with up to 45 percent GS filled content

High-strength, hermetic welds: the welded joints produced through spin friction welder exhibits excellent strength and can provide airtight seals

Low Energy consumption: plastic spin friction welder is a power-efficient process, contributing to cost saving and environmental sustainability

No consumables, fumes, or emission: unlike some other welding methods, plastic spin friction welder dos not require the user of additional filler materials and produces minimal smoke Suitable for complex geometries: plastic spin friction welder is particularly well-suited for application involving complex irregularly shaped parts that cannot be easily joined through other welding technique

04: Salient Characters

Large color touch screen with intuitive menu structure

Pneumatic cylinder actuator driven linear gear travelling mechanism

Welding time, dwell time, initiation distance and applied pressure all are adjustable

Password protection of setup parameter to avoid wrong or rube operation

Integrated design eliminates cables and makes installation more compact

Robust construction to avoid backward tilt in applying pressure

PLC Touch screen operation, simple operation and parameter setting

New mechanical, electrical and pneumatic designs

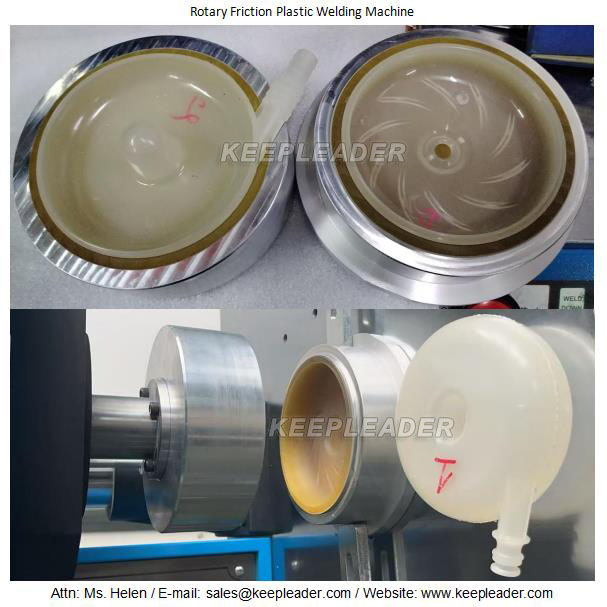

Detailed Image

The technology of Rotary Friction Plastic Welding Machine is well known, the heat needed to melt the parts is produced by a rotating motion combined with thrust pressure, one of the parts to be welded is hold by pneumatic clamping fixture, while the other one is set in motion by a rotating spindle, the assembly process is easy and based on easily understood, well-known principle of spin friction, welding joints are simple and permit a high degree of design freedom, the tools that hold the pieces to be welded are also simple and can b made by the client, the mechanical and electric solutions available create optimal working conditions with ample adjustment possibilities,make the Rotary Friction Plastic Welding Machine ideal for most welding applications

Machine Uses

Rotary Friction Plastic Welding Machine has basic demands on its joining designs, which is essential for obtaining a proper weld, they can have different shapes according to the type of application and the tightness of the items, the melt material can be contained inside a collection channel, the size of the weld joint have to provide sufficient clearance for ensuring free rotary motion, during the design stage, it is a good idea to provide for the possibility that the part can easily be held by the fixture and by the rotary spindle

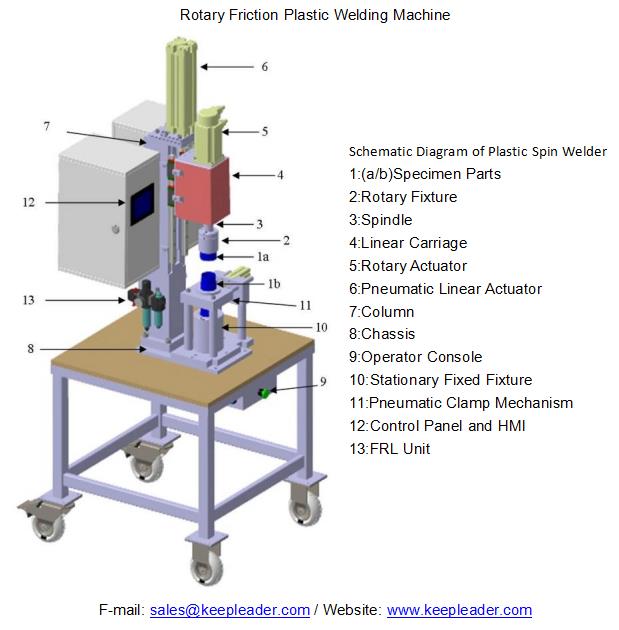

Schematic Diagram

Rotary Friction Plastic Welding Machine can apply spin friction to melt the jointing interface, which have good welding effect on water-proof,we accept customization of dimension, configuration and tooling kits for individual production

Contact Us

KEEPLEADER, we are professional manufacturer of plastic welding scenarios, Rotary Friction Plastic Welding Machine is prominent solution for axisymmetric circular/round plastic halves bonding, particularly for semi-crystalline, such as PP,PE,PET, PC, and other polymer with GS fillers,keepleader possess a wealth of established and proven expertise within the field plastic spin friction welder, and recognize the importance of quality component manufacture within the supply china, so just how can this manufacturing principle be applied, whether through capital investment, or subcontracting, this cost effective joining method is still hugely under utilized, meet some of industry’s leading authorities on Rotary Friction Plastic Welding Machine and understand the plethora of benefits that can be achieve, contact us today to see what more keepleader can replenish your business

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader