Corflute PP Boxes Making Ultrasonic Spot Welder_Flute Board_Hollow Grid Plate_Corrugated Totes Plastic Container Welding Machine

Corflute PP Boxes Making Ultrasonic Spot Welder

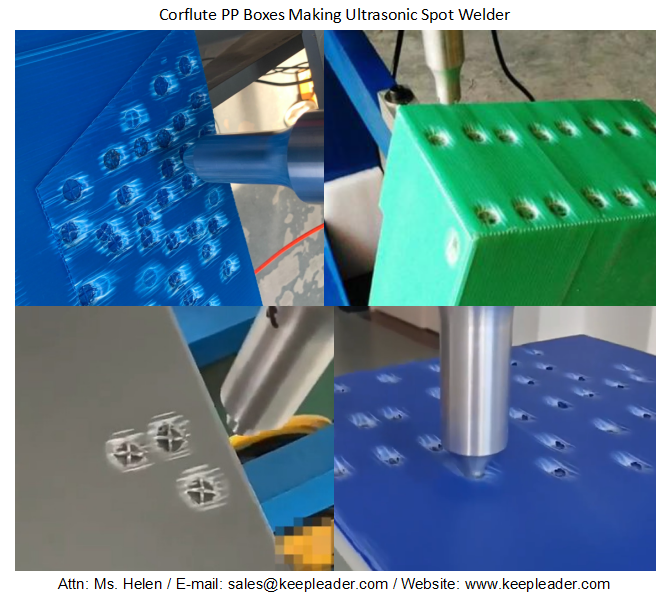

Corflute PP Boxes Making Ultrasonic Spot Welder is classified as standalone spot welder, the corrugated sheet has not weld preparation (ED), the prolonged tip of welding head penetrate into the stack PP Twin-wall sheets through the upper part into the lower parts, heat is produced on the contact surface of the molding, as a result of which the PP corrugated board is plasticized and welded, the expelled plastic flows upwards or molded into the welding head in flat and indented points, the back of the lower part remains largely free of marks, the welding head is fixed appropriately by hold-downs in specified clamping force, the thickness of the molding adjacent to the ultrasonic horn not exceed 8mm, multiple points welds can coordinate into one mold

Machine Description

Corflute PP Boxes Making Ultrasonic Spot Welder

01: Introduction

Corflute PP Boxes Making Ultrasonic Spot Welder for Polypropylene corrugated containers/totes is highly efficient tools designed for creating durable, robust and aesthetically pleasing welds without adhesives, bolts, staples or fasteners, ultrasonic vibration assemble is integrated with cantilever frame. Which utilize high frequency ultrasonic vibration to generate heat at the interface of Dual-wall hollow sheets, melting and fusing them together, because of suspended holding mechanism has depth beam, which gratifies versatility in loading height and depth, the operator is maneuverable in operation and alignment with pedal switch

Key features of Corflute PP Boxes Making Ultrasonic Spot Welder

Non-invasive joining: No need for adhesives or screws, clean and environmentally friendly process because of ultrasonic cold bonding criteria in instantaneous process

High Efficiency: Fast welding cycle times, reduce production downtime

Strong Welds: Produces uniform, reliable and tamper-proof joints,perfect for applications requiring durability and precision

Material Compatibility: specifically designed for PP and other thermoplastic materials, ideal for corrugated sheets and box manufacturing

Precision and Control: Adjustable power intensity for various thickness, consistent results with minimal operator intervention

Advantages of Corflute PP Boxes Making Ultrasonic Spot Welder

Save Cost: No consumables required, such as glue, staples

Environmentally Friendly: reduce waste production, no consumptive additions during process

Compact and Portable: Lightweight and ergonomic design for easy handling

Customization: Tailored Loading height and depth and specified tooling kits for versatility

Applications of Corflute PP Boxes: Packaging industry: for creating corrugated PP boxes for shipping and storage; Food and Beverage: Hygienic packaging solution; Electronics: Protective packaging for delicate items; Automotive: Storage or transportation bins for parts

Factors to consider when buying Corflute PP Boxes Making Ultrasonic Spot Welder

Welding Area Dimensions: Ensure the machine supports the size of boxes you need

Output Power: High power for thicker or larger materials, but, the factory usually consider little bigger power, which can leave extended room

Frequency Range: typically, between 15khz and 20kz, but 40khz is available for us

Automatic Level: Choose between manual, semi-automatic or fully automatic systems

Manufacturing Support: Availability of service, maintenance and commissioning, keepleader is professional manufacturer, we can provide user manual, tutorial video and 24 house on-line Tech consultation, and on-line trouble-shooting and ultimate resolution to remove the defects

02: Parameter

Name | |

Model | KLC-2615L/KLC-2020L |

Ultrasonic Power | 2600w/2000w |

Ultrasonic Frequency | 15khz/20khz |

Electric Connection | 220v/50hz or 110v/60hz Single Phase |

Delay Time | 0.01-9.99 S |

Welding Time | 0.01-9.99 S |

Holding Time | 0.01-9.99 S |

Driven Mode | Pneumatic |

Stroke Distance | 75mm |

Welding Area | Within 200mm, multiple Pronged Heads are available |

Coroplast sheet | 3mm,4mm and 5mm |

Horn Material | Titanium or Aluminum |

Material | Mild Steel |

Frequency Control | Automatic Tuning |

Cooling Mode | Air Cooling |

Working Pressure | 0.4~0.7Mpa |

Packaging Dimension | 1400*1000*2000mm |

Gross Weight | 380kgs |

03: Salient Characters

The maximum working height: 1000mm and depth: 1000mm, both are also customized

PLC/HMI Touch Screen, which is quick, easy parameter input, monitor and adjustment

The basic adjustable parameters includes welding, delay, holding time and penetration pressure

Reliable Guarantee for easy installation, operation, maintenance and commissioning

Ultrasonic Frequency varies from 15khz, 20khz, 28khz and 40khz in configuration

Quick application changeover, high welding seam strength

Precise and high quality imported pneumatic parts

High Quality ultrasonic stack mechanism and intelligent ultrasonic generator

Suitable for high cadences and short cycle times

IC Circuit precision control, automatic overload protection system

Adjustable horizontal level, easy control and replace welding horn

Single robust Column Cantilever frame, which is easy and convenient to operate and align

Precision fine adjustment of driven, clamping mechanism

Linear rack ensures long time and high precision movement of the welding head

Four-point adjustable structure is easy and convenient to adjust the mould

Digital high-precision power trigger function, time mode triggers ultrasonic that stable welding

Auto matching ultrasonic frequency to keep the acoustic tool in optimal performance

Detailed Images

The application of Corflute PP Boxes Making Ultrasonic Spot Welder has advantages

Fast welding Speed: the cycle welding process can be achieved within the fraction of second, ultrasonic vibration can generate quick joining heat within one second

Good welding effect: Ultrasonic Spot Welder can be carried out on lamination in a very fine scale to achieve point fusion

Energy saving: ultrasonic vibration generates molecular heating, which solely focuses on the contact area within fraction of seconds without downtime preheating

Efficient automation: Ultrasonic spot welder is triggered by pedal valve switch, which can free hands to load the corrugated sheet and align the position, after done, the pedal switch can start a cycle execution automatic without additional human interference.

Environment protection and high efficiency: no chemical substances such as glue or adhesive need to be added in the process of ultrasonic spot welding, no harmful gas or waste will be generated, with need the environmental requirements

Low cost: quick welding horn replacement, minimum the operating cost, good matching between welding horn and transducer, high precision, which ensure the good welding of polypropylene corrugated containers

Machine Uses

Corflute PP Boxes Making Ultrasonic Spot Welder operates by inducing ultrasonic vibrating energy in PP Corrugated sheets that is converted into heat between the welded PP Corrugated laminates, frictional heat is produced so that PP Corflute sheet melt at the clamping points and an insoluble point fusion between laminates are forged within fraction of second, the melting points of both PP Layers is nearly equivalent which helps to form a uniform weld area, the welded area is usually as strong as the matrix PP corrugated sheet laminates

Contact Us

The working principle of Corflute PP Boxes Making Ultrasonic Spot Welder eliminates the adoption of adhesive and permit the PP corrugated sheet to point Fuse itself in molecular sale at localized clamping points, ultrasonic welding tech with the proper time setting and pressure is the least velocity reliable approach for polypropylene sheets points fusion, such as eliminate adoption of consumption, resulting in robust bonding, increase production time, keepleader, we dedicate in customization of configuration and dimension, hence, the controlling mechanism and loading height & depth all are made to order without additional charges, share your productive concerns with our tech team to navigate our accommodation, your anticipation is definitely obeyed in our construction

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader