Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner of Auto Parts_Aviation Components Vaporized Decontamination Bath

Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner

Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner employs condensation tech that participate solvent in a closed chamber to create a vapour that dissolves contaminants on metal and plastic parts, the solvent reach its boiling status via electric heating and the vapour created rises and condenses on the parts being loaded, dissolving the contaminants, the criteria gratifies versatile industrial cleaning process, such as aerospace, automotive, and electronics to cleaning precision components, because of extended depth of this Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner designates specified vertical loading depth, that can place helicopter hanging frame to complete submission vapor degreasing, we revamp the constructive particular to grain the reliability and durability

Machine Description

Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner

01: Application

Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner acquires another tech name solvent condensation cleaning, that executes powerful, efficient, sustainable and reliable degreasing process in a matter of seconds removes contaminants like machining oil, cutting fluids, waxes, solder flux, polishing, buffing agent, and more via solvent cleaning, many industries from electronics firms to aerospace companies to metal fabricators user Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner to precision clean metal and machined parts, because of the comprehensive and fast cleaning capability combined with no need for rinsing and drying, that utilizes non-flammable, non-hazardous, no-toxic, low boiling temperature and low surface tension azeotropic solvent, which can be recycled and reused for reduced operating costs

Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner pioneers reliability in industrial cleaning process, such as electronic: printed circuit board and other electronic manufactures use vapor degreasing for the removal of flux and polar contaminants from printed circuit boards and the cleaning electronic assemblies; aerospace: vapor degreasing is widely used by aerospace manufacturing firms for precision and general vapor degreasing for dye removal in non-destructive testing application, pre-plating and pre-coating cleaning and post-plating/coating and masking wax and adhesive removal; optics: cleaning of fingerprints, buffing and potting compounds and waxes; general metal fabrication and finishing: metal fabricators user vapor degreasing for the removal of typical fabrication on contaminants including greases, lubricants and cutting fluids

02: Tech Data

Keyword | Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner |

Model | KLE-1096R |

Electric Connection | 380v,60hz, Three Phase, Five Wires |

Max process Capacity | 1600*1000*3500mm |

Heating Power | 15000W |

Refrigerator Power | 5Hp |

Distilled Spraying Wand Power | 1000w |

Exhausting Pump Power | 500W |

Solvent Capacity | 320 Liters |

Low Level Control Depth | 100~200mm |

Max Loading Weight | 800kgs |

Distillation Rate | 120L/H |

Temperature Control | Within 100 Celsius |

Vapor Zone | 1600*1000*980mm |

Maximum Loading Height | 3500mm |

Heating-up Time | 5~10 Minutes |

Material | Stainless Steel 316 of thickness: 3mm |

Overall Dimension | 1863*1264*4655mm |

Packing Size | 4.75*1.95*1.58m=14.63 CBM&1.5*1.0*1.5m=2.25CBM |

Weight | 1680kgs |

03: Salient Characters

Vapor condensation cleaning and drying in one chamber

Refrigerated primary condenser and Chilly water secondary cooling blanket

Extended free-board ratio to minimize diffusion losses

Manually hermetic sealing tank cover to control overhead air turbulence losses

Water separator continuous remove condensed atmospheric moisture from the system

The level and temperature of vapor automatic monitoring to alert operator in timely maintenance, service

All Chamber, canister and coils made of stainless steel 316, wall thickness 3mm.

Copper/brass plumbing's and, stainless cooling coils

High vapor sensor and high solvent temperature sensor to cut off heater and halt the refrigerator.

Low solvent level control, disables heaters and advises operator if solvent level is low

Hand-held distillate spray wand to execute flexible solvent jet blasting

Designed to use all types of non-flammables degreasing solvent.

Pickled, passivation and electron polished to extend operation life.

Heated tanks have direct contact tube heaters for energy efficiency and longevity.

On-board distillation ensures clean solvent continuously.

Free-board dwell ensures completely dry component at end of process.

Compact footprint designed for clean room application

Easy to use-minimal operator training required

Built-in top exhausting fan to control the solvent vapor dissipation

Hanging type refrigerator decide accept flexible installation

Supportive frame at the beneath of tank can bear maximum 800kgs loading

four sectional square compose a completed vapor chamber with reinforced welding seam

Standing-along power cabinet is convenient moveable during integrated installation.

Detailed Images

Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner should take advanced consideration precede applicable recommendation or solution, such as subsequent elements.

Chamber size: sizing of the vapor degreaser is fairly straight-forward as it is dictated by the weight and size of the part basket, this is usually a combination of the amount of parts tht need to be cleaned/production rate, the weight and size of the parts, how complex the parts are and type of contaminant that is being cleaned; production through-put: start by considering how many parts need to process an hour, keep in mind the larger the tank of vapor degreaser, the more expense; size and complexity of parts: the size will dictate the number of parts per basket or increasing the tank size for processing, and complexity might mean immersion or ultrasonic is needed; weight of part: heavy parts require more heat input to ensure the vapor zone does not collapse when the parts are immersed in the zone; contaminant type: light machining oils require less processing, and possibly just vapor cleaning versus needing immersion or ultrasonic to clean the parts; electrical needs: ultrasonic and heat requirements will dictate electrical needs; floor space: even though the Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner is pretty compact system, the refrigeration systems require air circulation//good ventilation; automation: automated basket handing system and hoist systems are available to provide consistent basket processing and thus consistent cleaning; ceiling height: large systems can be tall, so ceiling height does become a consideration; door frame restriction: moving the degreaser from shipping dock to final location might mean doors; ventilation: overhead ventilation is not recommended as it reduces the efficiency of refrigeration systems on the Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner by pulling the solvent past the refrigeration coils, ventilation is usually at the floor if at all; chiller capacity: on the larger units, the chiller for the primary refrigeration unit is usually placed outside or in a separate location, the secondary refrigeration system is usually on the platform with the vapor degreaser itself

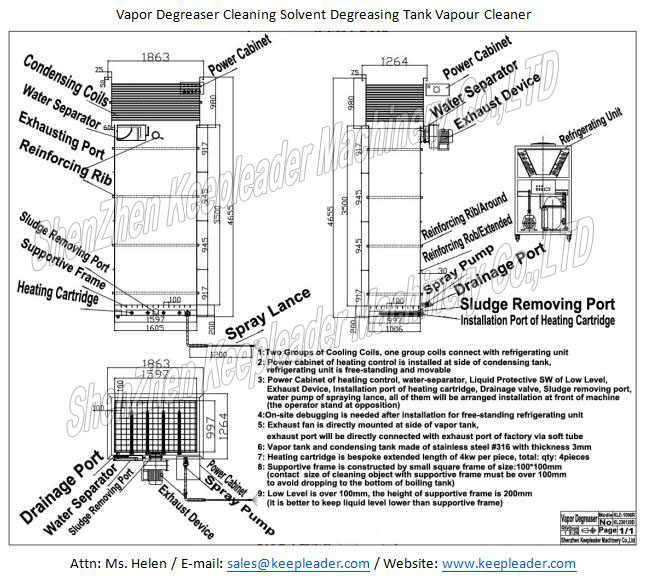

Illustration Drawing

Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner wins applause because of its decades proven characters, such as superior cleaning performance and effectiveness; no dependence on manual cleaning to apply consistent cleaning results; solely distilled pure solvent participate the whole cycle cleaning procedures to prevent cross contamination; once the cleaning data are accommodated, the operator can follow specified recipes to achieve repeatable cleaning schedules; solvent condensing cleaning, solvent immersion cleaning, distillation recycling and ultimate drying all in one chamber, that is quick no extra process required; super-fast, cycle time of about 5 to 6 minutes, based on non-flammable, no-toxicity solvent, no risk of corrosion, because no water is used; low energy consumption, less than half of traditional heated systems; all necessary cleaning steps concentrate in one tank, that has small footprint, take up little space; legislation drives the innovation of new generation of solvent to comply the administration in environment and safe operation

Machine Uses

Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner can solve the majority of problems in industrial cleaning process, typically for precision metal parts, many times, manufactured parts need to be painted, soldered, welded or electroplated, or they may require some similar processes to prepare them for assembly, many barriers are associated with improperly cleaned parts, all of these condition could create weaker, less desirable finished products, and in face, would be unlikely to pass through quality control, clean parts are safer, stronger and more durable for Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner, if surface has residue left from manufacturing process, any finishes applied to them will not coat evenly, this may leave raw metal exposed on the pieces, inviting rust and corrosion, welds on uncleaned or greasy surface may not fuse tightly, resulting in cracked or porous weld joints, these failed welds can be dangerous, inconvenient and expensive

Contact Us

Cleaning is critical to achieve a high quality aerospace parts surface finish, by using a Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner and modern, advanced cleaning solvent fluids, the cleaning process is simple, consistent and sustainable producing perfect prepped parts, Vapor Degreaser Cleaning Solvent Degreasing Tank Vapour Cleaner is cost-effective in ensuring parts are clean, and it addresses worker safety, regulatory requirements and environmental concerns, whatever you solely have perception or practical proven prototype, by which to initiate your collaborative fabrication, keepleader, we are definitely a reliable partner to trust in implementing your construction, now, we are ready for your tech consultation, don’t hesitate to contact us when you are engaging in industrial cleaning process

☺ Attn: MS Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784(Wechat/WhatsApp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader