High Frequency Treadmill Running Machine Belt Joint Welder of PVC_PU_Conveyor Belt Seam Jointing_Soldering HF Welding Equipments

High Frequency Treadmill Running Machine Belt Joint Welder

High Frequency Treadmill Running Machine Belt Joint Welder is applied in welding of treadmill belt, running machine belt, conveyor belt, transmission belt and industrial belt, molecular flip in electromagnetic field without union generate inside of polymer material itself heating to reach melting point in achieving soldering after quick solidification under sufficient pressure, specified high frequency electrode can forcefully clamp the cleats, sidewall, flights, baffles or strongly press the fingered seam of splicing, and qualified for versatile length, thickness sealing in belting building production

Machine Description

High Frequency Treadmill Running Machine Belt Joint Welder

01: Application

High Frequency Treadmill Running Machine Belt Joint Welder is high frequency dielectric sealing technique in treadmill belt splicing process, also is capable for industrial belt, transmission belt, running machine belt and conveyor belt in its welding/bonding/sealing of splicing joint, baffles,Cleats,flights,skirts, V-guides, PVC,PU,belts have high dielectric constant, in this process, an electric field is generated near the joint of belt connection, the direction of which is alternated approximately twenty-seven million times a seconds, every time the electric field changes, the dipole molecules of the polymer attempt to flip around to realign by inertia and friction, the molecules do not slip in union, this constant relative movement of the molecules results in inter-molecular friction which results in heat and subsequently melting and final solidification under pneumatic driven pressure, because of molecular sealing resulting in hermetic sealing and robust bonding, its jointing strength usually as strong as the matrix material with cosmetic appearance, in order to apply clamping force during welding, this belt joint welder is equipped with specified fixture or clamping high frequency electrode in its length, width and configuration

02: Parameter

Name | ||

Model | KLR-15KW | KLR-25KW |

HF Power Output | 15kw | 25kw |

Input Power | 25KVA | 35KVA |

Oscillating Frequency | 27.12Mhz |

|

Line Voltage | 380v,50hz or 220v,60hz Three Phase | |

Driven Mode | Pneumatic | Pneumatic |

Rectifier | Silicone Diode | Silicone Diode |

Oscillation Tube | 8T85RB | 8T85RA |

Max Pressure | 1500kgs | 2000kgs |

Gap of Electrodes | 250mm | 250mm |

Stamping Stroke | 150mm | 150mm |

Size of upper Electrode | 150*800mm | 150*900mm |

Size of Lower Electrode | 250*900mm | 250*1200mm |

Max Melting Area | 450cm2 | 600cm2 |

Temperature | 30~ 200 degree / adjustable | |

Welding timne | 0~30s/adjustable | |

Productivity | 2500times / 8hours | |

Air Pressure | 6kgs per square centimeter | |

Arc suppressor | NL-5557 High sensitive Device | |

Welding Time | 0~60s | 0~60s |

Net Weight | 1200kgs | 1500kgs |

Packing Size | 1800*1100*1960mm | 1900*1100*1980mm |

03: Character

Material trough is deep and wide, can go trough large material in heavy duty production

Adopting high sensitive spark protective device to avoid damaging mold and material

Robust construction supports longest welding extended to 800*1000mm

European square oscillation cabinet is more reliable and stable in HF/RF output

T,L cleats, sidewall of conveyor belts and finger of treadmill belt joint all are available

Auto coherent tuner to keep the high frequency at 27.12Mhz with lowest fluctuation

Low consumption coaxial oscillator, coherent tuner, strong output to reduce welding time and increase production by strong power generated

Configuration of supporting quick replace tooling to reduce downtime during changeover

High efficient tuning for different power output to achieve jointing of versatile length and thickness in improving effective and efficient welding

Reinforced frame is stable and durable in applying sufficient pressure in melting

Auto ascending and descending protective enclosure to avoid accident access

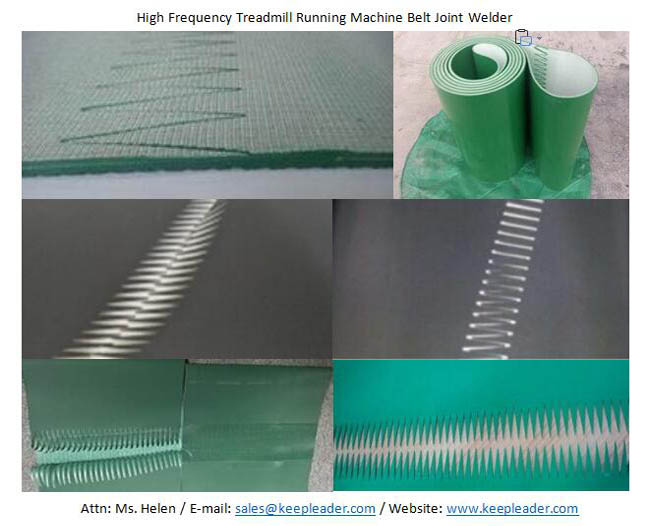

Detailed Images

High Frequency Treadmill Running Machine Belt Joint Welder has salient features of #1: compact structure to save the footprint #2: deep material trough for large size alignment in welding position #3: Coherent tuner to keep the HF power output stable #4: Built-in anti-sparkle device to protect the mold and material in case of over-current #5: having auxiliary protective enclosure to avoid wrong access during working #6: equipping coaxial oscillation box #7:Gray-white baking furnish #8: optional power output with specified high frequency electrode and fixture for versatile production #9: PVC, PU, TPU or All any other thermoplastic is acceptable in bonding process #10: supporting quick changeover welding mold #11: foot pedal or start buttons to trigger the machine #12: affordable price, reliable quality,consistent result and robust construction

Machine Uses

High Frequency Treadmill Running Machine Belt Joint Welder is not only capable for treadmill belt splicing but also capable for profile sealing of conveyor belt, transmission belt, industrial belt made of PVC, PU, TPU, its High frequency pressing electrode has optional of welding platen or fixture with clamping in holding the profile in pressed melting, the maximum bonding length usually depends on High frequency power pf which to couple with specified tooling

Contact Us

High Frequency Treadmill Running Machine Belt Joint Welder is not only capable for treadmill belt splicing but also capable for profile sealing of conveyor belt, transmission belt, industrial belt made of PVC, PU, TPU, its High frequency pressing electrode has optional of welding platen or fixture with clamping in holding the profile in pressed melting, the maximum bonding length usually depends on High frequency power pf which to couple with specified tooling, we are always ready for listening your individual production to work out a reliable, affordable and consistent welding solution

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader