Hollow Board Spot Welder Corflute Box Making Ultrasonic Welding Machine for Turnover Box Plastic Corrugated Sheets Spot Bonding

Hollow Board Spot Welder Corflute Box Making Ultrasonic Welding Machine

Hollow Board Spot Welder Corflute Box Making Ultrasonic Welding Machine is the process of creating intermolecular friction bond on overlapped corrugated sheet in making corflute box making,offering superior strength and often drastically reduced cycle times, mechanical jointing (snap fits, screws) and chemical bonding (adhesives)

Machine Description

Hollow Board Spot Welder Corflute Box Making Ultrasonic Welding Machine

01: Application

Hollow Board Spot Welder Corflute Box Making Ultrasonic Welding Machine is professional solution of turnover box/crate/basket building made of PP corrugated sheet in Ultrasonic Spot Bonding, the sheet usually, the machine has large structure of Height and Throat Depth for maximum welding size within 1 meters, the user can adjust the fixture to satisfy various sizes and shapes, ultrasonic welding technology comes instead of conventional gluing process, it is the fast and economical approach to improve the productivity, save the consumption

In corflute box making, ultrasonic vibration, applied to overlap of two layers of corflute sheet under pressure,generate sinusoidal standing waves throughout the corflute box being welded at frequency 15khz, in a viscoelastic material, such as a thermoplastic of PP semi-crystalline, this energy produced under sinusoidal strain is dissipated through intermolecular friction, resulting in heating building in bonding area of corflute sheet

Corflute Box usually made of semi-crystalline Polymers which are characterized by regions of ordered molecular structure, a high amount of heat is required to disrupt this ordered arrangement, the melting point is sharp, and re-solidification occurs rapidly,when in the solid state, semi-crystalline molecules are sprint-like and absorb a large part of ultrasonic vibration instead of transmitting them to joint interface, so large amplitude is necessary to generate sufficient heat for PP corflute sheet overlap spot welding, resulting in 15khz is considered in priority

02: Parameter

| Name | Hollow Board Spot Welder Corflute Box Making Ultrasonic Welding Machine |

| Model | KLC-2615L |

| Ultrasonic Power | 2600w |

| Ultrasonic Frequency | 15KHz |

| Driven Mode | Pneumatic |

| Power Supply | 110V/220V, 50Hz/60Hz |

| Stroking Distance | 70mm |

| Air Pressure | 0.6Mpa |

| Vibration System | Auto Stimulating |

| Output Time | 0.1~99S |

| Air Compressor | 1HP |

| Welding Area | 200mm |

| Max Input Power | 1.2kw |

| Dimension | 300*200*850mm |

| Weight | 200kg |

03: Character

Welding points from 1 to 4 are optional

The depth of pressing down is selectable

Melting depth is sophisticated under controlled

The joints are repeatable, clean with good precision

Digital display menu to set the welding data in operation and setting

Robust construction and compact structure for heavy duty production and room saving

High standing column and deep throat for various size corflute box welding

No blot or glue, reduce labor and costs (no adhesives, screws, connective bolts)

Finished corflute box is intermolecular friction bonding without chemical added

Auto tuning and frequency sweeping to guarantee the upmost sinusoidal standing wave

Corflute box is very fast in building by ultrasonic bonding, welding time is only within 1 seconds

The welding joint has same strength as the corflute sheet itself to bear the tension and tearing force

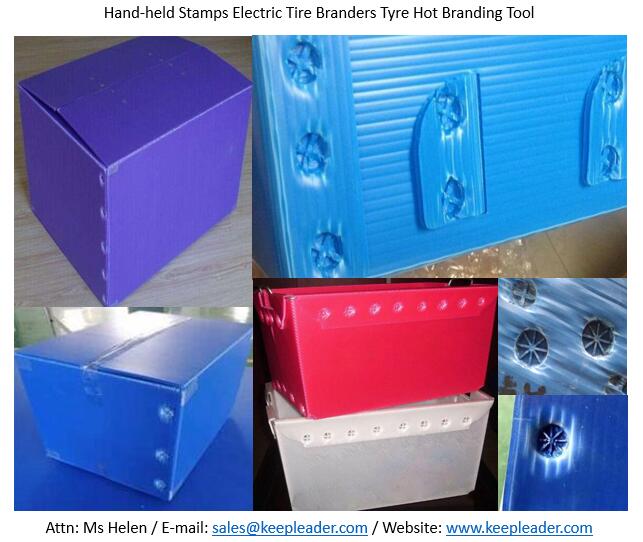

Detailed Images

Hollow Board Spot Welder Corflute Box Making Ultrasonic Welding Machine is free-standing constructed with deep throat in spot bonding corflute box in various sizes, the ultrasonic horn/sonotrode is selectable in welding spots from 1 to 4 within maximum length: 200mm, the directly contact melting points can be built in your demands of its shape,size, and melting depth and surface pattern

Machine Uses

Hollow Board Spot Welder Corflute Box Making Ultrasonic Welding Machine is cold bonding process in corflute box making by intermolecular friction resulting in heating, melting and solidifying without mechanical and chemical process, which can enhance productivity, save labor force and without consumption in good appearance and bonding strength

Contact Us

Hollow Board Spot Welder Corflute Box Making Ultrasonic Welding Machine is only of ultrasonic welding technical solution in corflute box making, we, keepleader is not only a professional manufacturer but also a reliable cooperator to work with you in improving your productivity at an affordable pricing, please contact us to find what more we can do for you

☺ Attn: Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone:+86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader