Stencil Ultrasonic Cleaning Machine for Circuit Board_Silkscreen Stencil Cleaning Ultrasonic Cleaner of Stencil Washing Machine

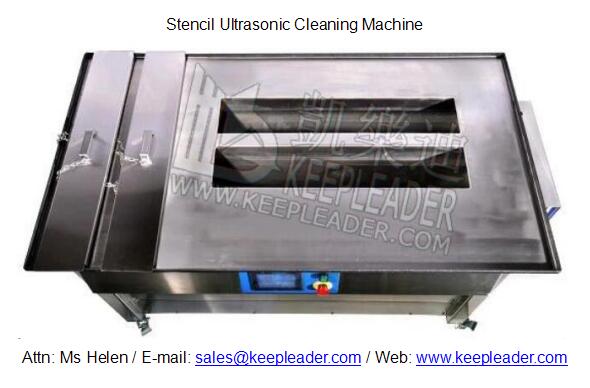

Stencil Ultrasonic Cleaning Machine

Stencil Ultrasonic Cleaning Machine composed Two Chambers in #1: Ultrasonic vibration jetting/scrubbing #2: Rinsing with or without ultrasonic energy in optional configuration

Machine Description

Stencil Ultrasonic Cleaning Machine

01: Parameter

Name | |||

Model | KLE-1046S | KLE-1049S | KLE-1070S |

Ultrasonic frequency | 40khz | ||

Ultrasonic power | 2300w | 2500W | 3500w |

Applicable stencil size | 550*600mm | 550*650mm | 736*736mm |

Inner size | 650*500*700mm | 650*500*750mm | 840*500mm*840 |

Power line supply | 380V/50hz*3P | ||

Cleaning time | 3 minutes | ||

Drying time | 5 minutes | ||

Outside dimension | 750*600*1100mm | 750*600*1150mm | 940*600*1250mm |

Weight | 140kgs | 150kgs | 210kgs |

02: Highlights

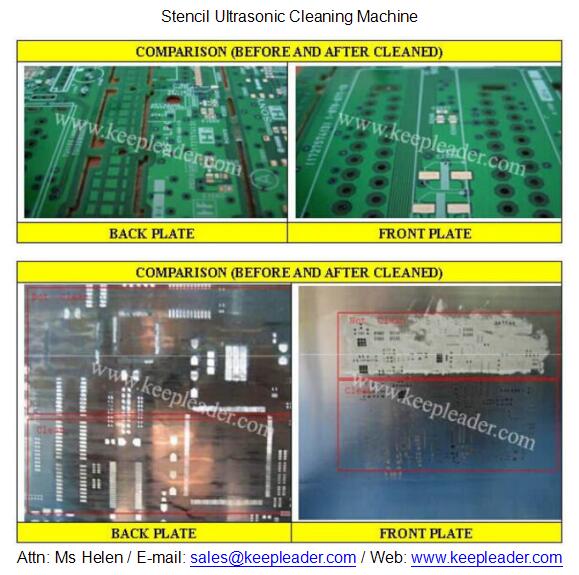

Stencil Ultrasonic Cleaning Machine can remove all types of un-reflowed solder paste, including lead-free, as well as uncured adhesives from stencils, screens and misprinted PCBs, safely and gently, its built-in wash-solution filtration and recirculation system cuts down on the amount of wastewater sent to drain while maximizing the useful life of your wash solution

03: Cleaning procedures

Simply place your stencil in the rack, fill with high quality cleaning solution and press the start button, ultrasonically cleaned by high-speed microscopic bubble implosions, after only a few minutes, manually lifts your cleaning stencil from the washing tank, and spray-clean by hand to remove the loosened solder paste and other contaminants. And dip into the rinsing tank, at last, use a low-pressure dry air gun removes the remnant rinse moisture and you stencil is ready to be used again all in only a few minutes

04: Advantages

041: Complete cleaning: microscopic, ultrasonic removal of solder pasts, post solder flux and more

042: Minimize wash solution costs: The machine built-in filtration and recirculation system to reduce the water consumption and reuse the wash solution

043: Adopts ultrasonic cleaning technology: Stencil Ultrasonic Cleaning Machine is using ultrasonic vibrating to stir and remove the un-reflowed solder, paste and uncured adhesives from stencils screens and misprints, gently and without risk of damage to delicate stencils

044: Washing, rinsing and drying functions are all in one machine: The machine design two sump, one is used for dirty cleaning, the other using rinsing, also built-in hot air drying system to quick dry after cleaning, all workstation included in one compact unit, minimizing required floor space

045: Customized size for various sizes of stencils: accommodates stencils, screen, and misprinted PCBs to 29”*29” (736*736mm)

046: Water level indictor: shuts down the machine if the water level drops below the minimum requirement to avoid damage

047: Dual tanks design: stencil ultrasonic cleaner has two ultrasonic tanks, a wash tank/sump and rinsing tank/Sump, both tanks have ultrasonic energy and heat, the cleaning tank equipped with filtering and recirculation to save the water consumption, reuse the cleaning solution and avoid secondary detain when pulling out the cleaning tank

048: Top quality: the ultrasonic vibrators are mounted at side of cleaning tank at 40khz, have ten year warranty against the be-bonding, the whole machine has two year of warranty, ultrasonic generator is smart to match the frequency with the machine, don’t need any further debugging, and support hog plug

Easy loading and unloading: low-profile, top-centric design requires no or minimal bending

Portability: the entire systems moves easily around your shop on casters

049: Easy maintenance: with easy-to- access, easy-to-replace parts, easy to program and operate.

05: Special notices

051: The ultrasonic frequency should be 40 kHz or higher (the lower the frequency, the more aggressive the ultrasonic cavitations)

052: The power density should be 10 watts per liter or less (this is the amount of electrical energy transferred into the cleaning bath via the ultrasonic generator, measured in watts per liter of cleaning solution in the tank).

053: The ultrasonic cleaning cycle should be less than 10 minutes (a correctly sized ultrasonic cleaner combined with the appropriate cleaning chemistry should effectively clean PCBs in 3 - 4 minutes).

Detailed Images

Stencil Ultrasonic Cleaning Machine has basket/holder to suspended in the cleaning tank, filter inter-circulation system and High pressure spraying gun are optional configuration

Buying Guides

TECHNOLOGY SUPPORT of Stencil Ultrasonic Cleaning Machine

Performance comparison of stencil cleaning

01: Manually soak stencil cleaning

011: cleaning steps

0111: Spray cleaning agent on the stencil or soak the stencil in a container for a while (if the solder have condensed into pieces)

0112: Put on gloves and use duster cloth to swab down the dirty parts containing solder paste

0113: Drying by compressed air

0114: Check and confirm the following

01141: Confirm the surface is now clean and solder residue has been removed

01142: Confirm the mesh without any clogging

01143: Confirm mark point has not been damage

01144: Confirm stencil tension

012: Advantages

0121: lost cost

0122: Visualization

013: Disadvantages

0131: Long time to clean and dry, low-effectiveness

0132: High salary cost, requires specialized worked cleaning for entire process

0133: Cleaning effect is not very good and depends on worker cleaning ability

0134: May damage stencil, human error can cause damage and man-handling

02: Pneumatic spray stencil cleaning

Tools and materials: Pneumatic stencil cleaning machine, cleaning agent, special gloves

021: Cleaning steps

0211: Start air compressor

0212: Set up the cleaning time, drying time

0213: Put in stencil and leave to do other work (frees the operator)

0214: Get Stencil out after coming back and put in another one (fully automated process, just need loading and unloading)

022: Advantages

0221: Pneumatic, automatic, without power

0222: high-effective

0223: cleaning effect is good

0224: Economize manpower

023: Disadvantages

0231: Cannot clean oversized stencils

0232: Cleaning effect is not good with thick stencils

0233: Requires certain cost to make initial investment machine

03: Stencil ultrasonic cleaning

Tooling and material: Stencil Ultrasonic Cleaning Machine, cleaning agent

031: Cleaning steps

0311: Power on

0312: Put in stencil and setting cleaning time and drying time

0313: Get stencil out and put in another one

032: Advantages

0321: Automatic

0322: Highly effective

0323: Cleaning effect is good

033: Disadvantages

0331: Need one stuff

0332: High cost

0333: Can’t clean oversized stencil

Structure Illustration

Stencil Ultrasonic Cleaning Machine is custom ultrasonic cleaner is optional in #1: Dimension #2: Function #3: Control System

Machine Uses

Stencil Ultrasonic Cleaning Machine is compacted Cleaning equipment in Circuit Board, PCB, Silkscreen Stencil Precision cleaning

Contact Us

Stencil Ultrasonic Cleaning Machine is one of Professional stencil washing equipment, we are pleased to provide our solution with experienced practical cleaning process and feedback from our cooperating partner, please feel free to consult with our tech team to find what we can do more for your application

☺ Attn:Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone:+86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: https://www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader