Aluminum_Copper Foil Welding Ultrasonic Metal Welder for Metal Aluminum_Copper_Nickel Foil_Sheet_Tab Ultrasonic Welding Machine

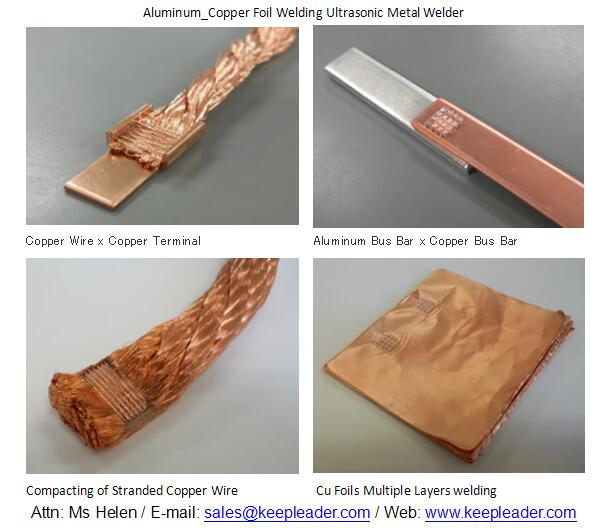

Aluminum_Copper Foil Welding Ultrasonic Metal Welder

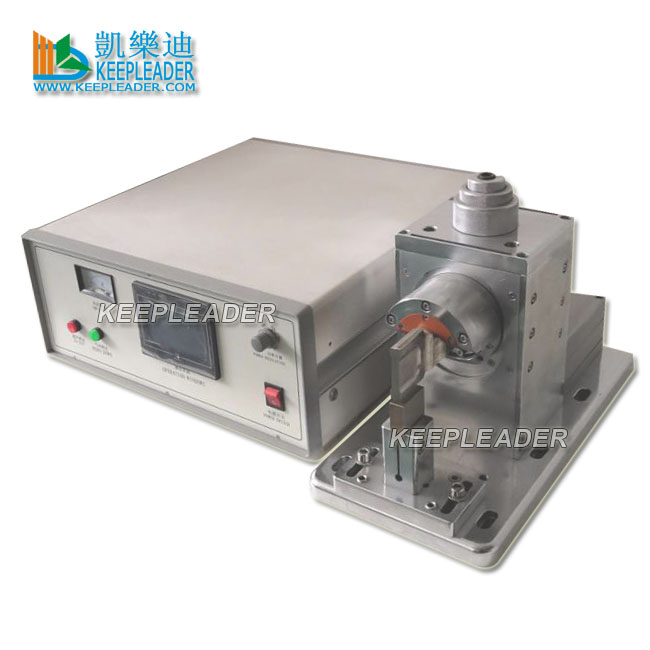

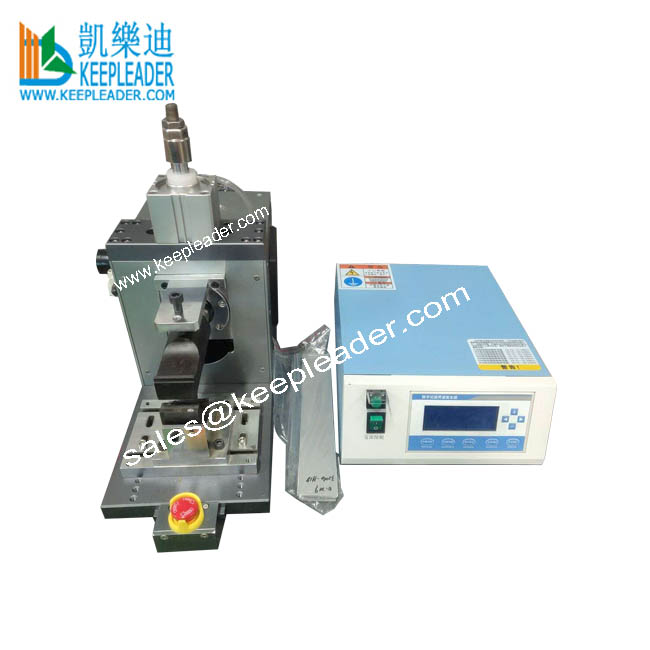

Aluminum_Copper Foil Welding Ultrasonic Metal Welder is 20khz of ultrasonic power: 2kw~5kw for non-ferrous metal bonding of codes: battery welding, electronic metal connector and wire bonding by changing upper ultrasonic horn/sonotrode and bottom fixture/anvil for versatile application

Machine Description

Aluminum_Copper Foil Welding Ultrasonic Metal Welder

01: Application

Aluminum_Copper Foil Welding Ultrasonic Metal Welder is designed for lithium battery tab welding with touch-screen controller, it is designed for welding stacked electrode sheets of copper and aluminum and tab onto current collectors to prepare Li-ion pouch cells,Aluminum_Copper Foil Welding Ultrasonic Metal Welder of 3600w can can weld stacked electrode with 60~70 layers of aluminum and copper foils, is also can applied for wire bonding, bonding scopes of rope stranded wire with flat cable welding; rotor and rectifier welding; rare metal electrical connector welding; large-scale wires and terminals welding; copper terminals with beryllium copper alloy welding; electromagnetic wire terminal welding; brush braided copper wire and primary power cable welding; multiple-wire ends welding; rope stranded wire with terminals welding; contact assembly welding; rope stranded copper wire with beryllium copper terminals welding; motor lead wire terminal welding; wire terminals and terminals welding; thick copper sheet with aluminum plate welding; braided line terminal and the motor brushes welding; battery connection welding, nickel-plated lead wire and platinum lead wire welding; small metal piece with metal mesh, metal foil welding, solid copper conductor with brass terminal welding; braided copper wire with brass terminal welding, welding of electrotype-brush holder components

02: Parameter

Name | |

Model | KLM-20KHZ |

Ultrasonic Power | 2000w~5000w |

Ultrasonic frequency | 20khz |

Source Voltage | AC 110V/220V+10%V, 50/60Hz |

Welding Thickness | 0.03~5mm Al and Ni Tab welding Aluminum/Copper Foil |

Welding Size | 5*5mm up to 50mm |

Pneumatic pressure | 0.3~0.6Mpa |

Stroke Distance | 15mm |

Power Regulation Mode | Frequency Auto-tracking, power adjustable 0~100% |

Freq tracking range | Equal or less 5Hz |

Power Stability | Equal or less 5% |

Terminal dynamic response time | Equal or less 10ms |

Over-current Protection Current | 10A |

Over-current Protection Time | Equal or less 10ms |

Over-Heat Protection Temp | 85 degree |

Working Temp | +5~50 degree |

Amplitude adjustment | Variable (30%`100%,1% step) |

Control Mode | Time/Depth/Height/Energy |

Monitor Mode | Time/Depth/Height/Energy |

Size | Ultrasonic generator: 420*380*200mm |

Welding Head: 510*280*210mm | |

Amplitude of vibration | 15~25um |

Weight | 68kgs |

03: Character

No special surface treatment required

Using the reliable piezoelectric ceramic transducer

Man-machine interface control, multiple-parameter storage

The welding time is short, without any flux, gas and solder

No welding sparks, environmental protection and safety

Compacted structure,space saving, easy to introduce automation

Compacted structure,space saving, easy to introduce automation

Energy detection mode, to ensure consistency of welding quality

Welding material does not melt, non-fragile metal properties

Then after the good conductivity and resistance very low or almost zero

Using phase-locked PLL frequency automatic tracking technology, without FM

Pairs of welding metal surfaces that require low, oxidation or plating can be welded

Step-less adjustment of the amplitude without the need for frequency replacement amplifier

Reduces damage and provides efficient energy use because of low welding temperatures (less than approx 50% of the melting point)

Suitable for connection of thin metal foil such as aluminum foil or thin copper foil, also suitable for connection of copper and aluminum wires

Machine Uses

Aluminum_Copper Foil Welding Ultrasonic Metal Welder is solid state bonding of precision metal parts by ultrasonic vibration scrubbing molecular inter-mingle coalescence as a disruptive metal bonding technology comparing with conventional laser welding, resistance welding, soldering and pulse welding

FAQ

High frequency asked question

01: How Does Aluminum_Copper Foil Welding Ultrasonic Metal Welder work?

Aluminum or copper foil to be joined are hold together between the ultrasonic horn and anvil, they experience ultrasonic vibrations of 20khz to 40khz depends upon application, 40khz is precision bonding of two layers of copper foil as better choose, vibration of the horn causes the aluminum or copper foil to scrub together (in shear) that remove surface contaminants to expose bare metal areas, the material’s atomic structures then co-mingle to create a strong, surface molecular, solid-state bond that is clean and has low electric resistance, these properties together make the process idea for electronic application and more, the most popular is electric wire bonding and battery anode and cathode multiple-layers Al and Cu Foil stack bonding

02: What strength is expected from materials joined ultrasonically?

Usually, the bond created is as strong or stronger than the parent material, for aluminum and copper foil seam sealing can have hermetic sealing effect

03: What metals can be joined ultrasonically?

Generally, non-ferrous metals: aluminum, silver, gold, copper, brass, nickel and alloys of these materials, applications include battery foil/tab welding, wire splicing, wire termination, spot welding, seam welding and copper tube sealing for the refrigeration industry

04: What about steel components?

Welding to iron, steel and stainless steel is not recommended because they are harder that non-ferrous metals, the surface structure are too dense and do not allow the transfer of the materials for consistent bonding, the parameters required would be more aggressive with heat build-up, resulting in increased tool wear, while bonding may occur, consistent weld strength is difficult to achieve

05: What about dissimilar materials such as aluminum to copper?

Aluminum_Copper Foil Welding Ultrasonic Metal Welder works well for dissimilar materials because the process is the same whether the materials are similar or not, examples include battery nickel, copper tab, aluminum foil welding, copper foil welding, silver-plated or copper stranded wire to nickel-plated copper or brass terminals, copper pads to aluminum heat sinks, and precious metal contacts to contact arms among others

06: What about plated parts?

It depends upon the plating, tin plating inhibits the bonding process, acting more like a lubricant, the tin heats up and may actually reflow, the parts slide over each other rather than rubbing against each other, heat builds up which has a negative effect, especially on wire strands, as they become brittle and usually break, silver and gold plating is different, these are mot compatible because they seem to move away from the weld surface or are able to be scrubbed through to get to the base metal, applications with these plating include stranded wire splicing and tipping, wire termination to plated terminals or lead frames

07: What are weld size and material thickness restrictions?

6mm square wire cross sectional bonding for 40khz and 20khz, bigger size must select 20khz, the material can be of any thickness on the anvil side of the weld as long as it can be held stationary either on the anvil or be clamping, on the horn side, material can be up to 3mm provided sufficient power is available from the controller

08: Can tooling be reworked for extended use?

Many times a horn or replaceable tip can be reworked (build-in the new knurling) one time, more if the rework allows the tool to remain to print or weight specification, stick anvils can build-in new knurling pattern as long as they can still be clamped in position in the tool support or clamping and hold the part as required or bear the shearing force during vibration scrubbing

09: Can the same tooling be used for different applications?

Most tooling is custom make for specific application, especially the fixture, the knurl patterns on the horn and anvil are specified according to material thickness and weld area requirements as well as part configuration, some tooling combination may be used for situation other than the original application, but may need modification

10: How much training necessitate operating a new machine?

Aluminum_Copper Foil Welding Ultrasonic Metal Welder is very easy to operate and do not require any certification, keepleader provides training when installing the machine, and application, training includes operations of the controls, how and when to change tooling, parameter setting and place multiple application setups in the present menu if needed

Contact Us

KEEPLEADER offers free sample welding service and tech consultation performed by experienced, precision weld engineers so the customer can verify the performance of the Aluminum_Copper Foil Welding Ultrasonic Metal Welder applied to their own sample, please fee free to apply for this service

☺ Attn:Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone:+86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: https://www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader