Ultrasonic Vapor Degreasing System of Industrial Cleaning Equipment Ultrasonic vapor Degreaser Steam Cleaning With Cooling Coil

Ultrasonic Vapor Degreasing System

Ultrasonic Vapor Degreasing System come in a variety of configurations depending on customer application, keepleader can size a vapor degreasing system to fit not only your parts, but also your circle time and production requirements, with today’s solvent it is essential to size the vapor degreasing system properly to ensure maximum solvent recapture through distillation cycle chilling coils

Machine Description

Ultrasonic Vapor Degreasing System

01: Application

Ultrasonic Vapor Degreasing System is excellent option for parts that have blind holes, tight cavitation, and/or solidified contaminant, keepleader manufactures a complete line of Ultrasonic Vapor Degreasing System uniquely designed for ultrasonic cleaning in your vapor degreasing should strongly be considered if you have any of the following conditions or concerns

011: contaminants containing inorganic contaminants such as salts, metal fines, buffing compounds or the inorganic components of a flux resin

012: contaminants that are baked on or cured or have difficulty being solubilized by your cleaning agent and parts have complex geometries, blind holes or crevices

013: by introducing ultrasonic cleaning into the vapor degreasing process, the capability of the system to clean in the previously mentioned contexts is dramatically improved, at a micro level, intense activity on the surface of the parts is possible to physically displace and dislodge hard to remove insoluble contaminants as well as reach blind holes, threads and cavities that conventional solvent vapor degreasing system cleaning would have difficulty reaching and cleaning, in addition, in many instances, the rate at which organic contaminants are cleaned is accelerated by the ultrasonic process

02: Using a Ultrasonic Vapor Degreasing System

There are only few steps to using Ultrasonic Vapor Degreasing System

021: select the operation model in manual and automatic, in manual mode, the lifting, ultrasonic cleaning, vapor cleaning, condensing dry all are manually start, pause, and stop in automatic model, the machine will complete a whole cleaning circle basing on programmed parameters, loading and unloading only necessitate manually completing

022: place the cleaning object in a basket or hanging tray/net holder

023: slowly lower the cleaning object into cleaning fluid vapors above the boil sump for the first few moments of cleaning, the vapors condense on the (relatively) cool parts and cleaning starts, any liquid cleaning fluid drips off of the parts and falls back into the boil sump

024: continue lowering the parts into the boil sump, the cleaning fluid wraps around the cleaning objects, goes into and out of the tightest spaces, and dissolves oils, greases and fluxes, this is where the heavy cleaning occurs, notice the gentle nature of vapor cleaning: there are no high-pressure sprays, no air knives, no high temperatures stressing the components, it is simple, fast and easy

025: remove the parts from the boiling sump and move them into the rinse sump, here, fresh, pure distilled cleaning fluid remove any final vestige of the contamination

026: once rinsing is complete, slowly remove the cleaning object from the rinsing sump, up through vapors and remove them from the machine, the parts come out clean, dry and relatively cool, ready for the next manufacturing process, for all in one tank Ultrasonic Vapor Degreasing System, the rinsing process is composed with ultrasonic cleaning

027: once rinsing is complete, slowly remove the parts from the rinse sump, up through vapors and remove them from the degreasing system, the cleaning objects come out clean, dry and relatively coo and ready for the next manufacturing process

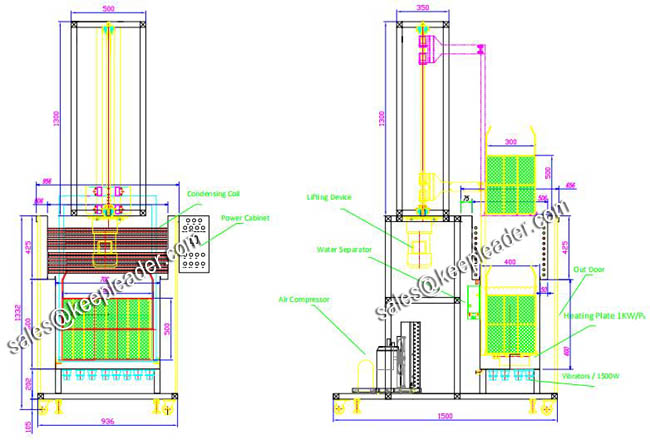

03:Parameter

Name | |

Model | KLE-1030RL |

Boiling/ultrasonic Sump | 700*400*600mm |

Heated Depth | 400mm |

Ultrasonic power | 1500w |

Heating power | 4~6kw |

Air compressor | 5Hp |

Ultrasonic frequency | 28khz or 40khz |

Transducers | 50w*15pcs |

Distillation rate | 120L/h |

Re-circulation | 4 gpm 10u |

Vapor Zone | 700*400*580mm |

Control Voltage | 24 volts |

Solvent capacity | 112L+ |

Overall Size | 1136*1500*2682mm |

Power Source | 380v,50hz or 220v,60hz three phase |

Shipping weight | 528kgs |

Higher frequencies available upon request, basing on HCHF, HFE and HFE solvent, specification subject to change without notice | |

04: Character

Digital temperature control and lighting alarm

Low level Float safety control and indicting light

Solvent cool down mode to minimize solvent loss

All in one tank, cost effective, and compact footprint

Stainless steel processor tanks with bright annealed finish

Stainless steel condenser and chiller coils to avoid corrosion

100~120% free-board ratio to minimize solvent consumption

Low voltage control, lift off shirt panels to facilitate maintenance

coolant indicator give visual confirmation the refrigeration is functioning

ready light and alarm to notify operator to load and unload cleaning parts

Manually operated removable cover to control overhead air turbulence losses

Cooling water primary condensing coil to condense the bulk of the solvent vapors

Removable tank sealing cover to entrap the vapor and reduce the emission losses

Digital temperature control and detector to visual confirm the heating functioning

Ultrasonic power is adjustable, frequency is auto tuning kept best performance

Water separator for continuous removal of condensed atmospheric moisture from the system

Refrigerated sub-zero free-board condenser to provide a cold air barrier minimizing fugitive losses

Effective with a variety of non-flammable solvents including chlorinated, brominated and fluorinated

Boiling sump mounted ultrasonic agitation to add vibration scrubbing to remove the robust and solidified contamination, also can penetrate tight cracks and bind holes

Detailed Images

Ultrasonic Vapor Degreasing System has customized configurations in #1: Size of boiling sunp+Vapor Zone+basket #2: function of PLC Touch screen+aut lifting device+ up & down agitation + removable tank cover #3: operation mode of automatic and manual in option

Function Illustration

Ultrasonic Vapor Degreasing System can have sized configurations, which are satisfied with your practical cleaning application in # basket size #2: cycle time #3: detergent #4: cleaning efficiency and capacity

Contact Us

Ultrasonic Vapor Degreasing System is composed ultrasonic agitation with convertional vapor degreasing system, which also can combine #1: multiple stages in immersible ultrasonic cleaning, immersible ultrasonic rinsing, distillation circulation #2: Full-enclosed circle cleaning not only cleaning stages but also transmission stages #3: intellectual operation of manual button Switch control and automatic PLC touch screen operation #4: extended auxiliary process of desiccant drying and spray wand

☺ Attn:Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader