Servo Ultrasonic Plastic Welding Machine of Servo Motor Driven Ultrasonic Plastic Welder for Digital Control Sonic Welder

Servo Ultrasonic Plastic Welding Machine

Servo Ultrasonic Plastic Welding Machine is #1: Servo Motor Actuator in Stroking Down #1: 20khz, 35khz, 40khz optional

Machine Description

Servo Ultrasonic Plastic Welding Machine

01:Application

Servo Ultrasonic Plastic Welding Machine is a thermoplastic welding technique that uses ultrasonic vibration of high frequency to weld the two pieces plastic together, it is most commonly used to weld Solid polymer materials in the fields of automotive, electronics, home appliances, industrial components, electrical wiring components, lighters, toys, gadgets, medical, personal appliances and more

02: Parameter

Name | Servo Ultrasonic Plastic Welding Machine | ||

Model | KLC-1020 | KLC-1035 | KLC-1040 |

Ultrasonic Power | 1KW~2KW | 0.3KW~1KW | 0.3KW~1KW |

Ultrasonic Frequency | 20khz | 35khz | 40khz |

Power supply | Phase voltage: 110v or 220v 50hz/60hz, single phase | ||

Cooling system | Air cooling | Air cooling | Air cooling |

Stroke pressing depth | 70mm | 70mm | 70mm |

Vibration system | Auto-stimulation |

|

|

Actuator | Servo-motor Driven | ||

Vibrating time | 0.01~2s |

|

|

Welding Size | 100mm | 30mm | 20mm |

Net Weight | 100~150kgs | ||

03: Character

Servo motor driven in pressing down

Horizontal adjustable structure of welding head, convenient mold adjustment

Robust column, linear guide bearing, precision line adjustment device

Automatic velocity calibration and welding initiation

Continuous sonic scan for converter, booster and horn stack

Digital frequency generation and control through 32-bit micro-controller

Monitoring of parameters and the number of welding processes

Protection against short circuit, no-load operation and overload

Ultrasonic auto-tuning keeps the machine best in resonance matching

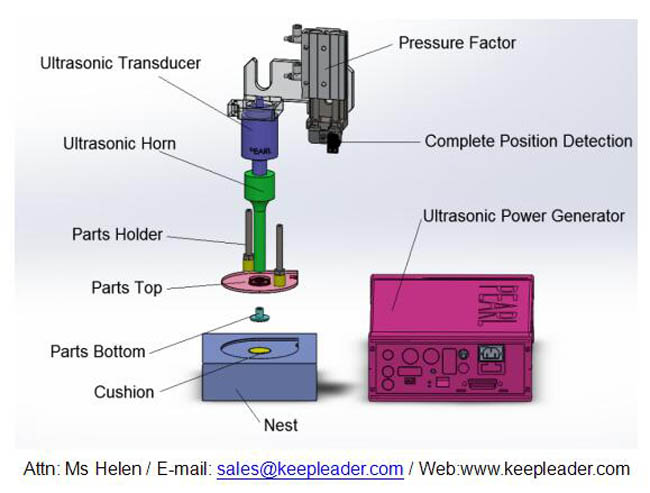

04: Tech Principle

High frequency (15khz, 20khz, 35khz, 40khz optional) ultrasonic vibration is used to join two plastic pieces together, the high frequency vibration generates heat energy at the interface of two pieces and melts the material, the melted material fused with each other to form a strong weld on cooling and solidification

Servo Motor stroking down: the press is used to apply pressure on the two plastic pieces to be joined, which also can be pneumatic driven type

Nest or anvil or fixture: it is a clamping device that is used to hold and clamp the two plastic pieces together, it allows the high frequency vibration directed to the interface of two pieces

Ultrasonic Stack: it is combination of ultrasonic transducer, booster, sonotrode/horn, these three elements are tuned to work on resonate frequency of 15khz, 20khz, 35khz and 40khz

Converter: it converts the electrical signals into high frequency mechanical vibration, and it does so through the piezoelectric effect

Booster: it modifies the amplitude of vibration mechanically, in some standard systems, it is used to clamp the stack in the press

Horn or Sonotrode: it vibrates at high frequency and transmits the mechanical vibration to the two pieces to be welded, it also modifies the amplitude mechanically, it takes the shape of the part, the horn is made of titanium or aluminum

Ultrasonic generator: it generates and delivers high frequency electrical signals matching the resonance frequency of stack

Controller: it is used to control the movement of the press and delivery of the ultrasonic energy

05: Working procedures

The two plastic pieces to be joined are assembled in the nest (anvil or fixture), the horn is made to contact at upper part of piece, a pressure is applied to the two pieces against the fixture, the pressure is applied through the servo motor driven press, horn is vibrated vertically at very high frequency, transmits the mechanical vibration to the two plastic pieces, this generates heat energy at the contact tip of the two surfaces and melts them, a clamping force is applied to the two pieces for a predetermined amount of time to fuse them tether to form a strong weld on cooling and solidification, after solidification, the clamping force is removed and horn retracted, the welded plastic part is taken out of the fixture as one piece

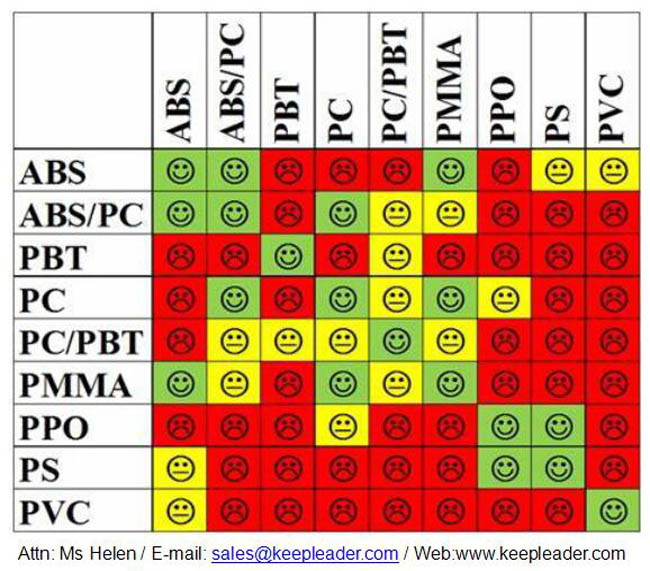

06: Buying guides

Please tell us following information to make a correct recommendation

The material of your welding parts

The definite size of your products in welding

Welding requirements

3D drawing if you have

It is better if you can send us the picture of welding object

KEEPLEADER can also make the Servo Ultrasonic Plastic Welding in your demanding

Detailed Images

Servo Ultrasonic Plastic Welding Machine is servo motor driven in each mechanical process of ultrasonic welding

Functional Illustration

Servo Ultrasonic Plastic Welding Machine has exceptional configuration of servo motor driven system

Buying Guides

Servo Ultrasonic Plastic Welding Machine is available for thermoplastic object in amorphous and semi-crystaline

Contact Us

Servo Ultrasonic Plastic Welding Machine is satisfied with custom's practice, please help us with your favourited configuration to make a proper quotation for you

☺ Attn:Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat / Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader