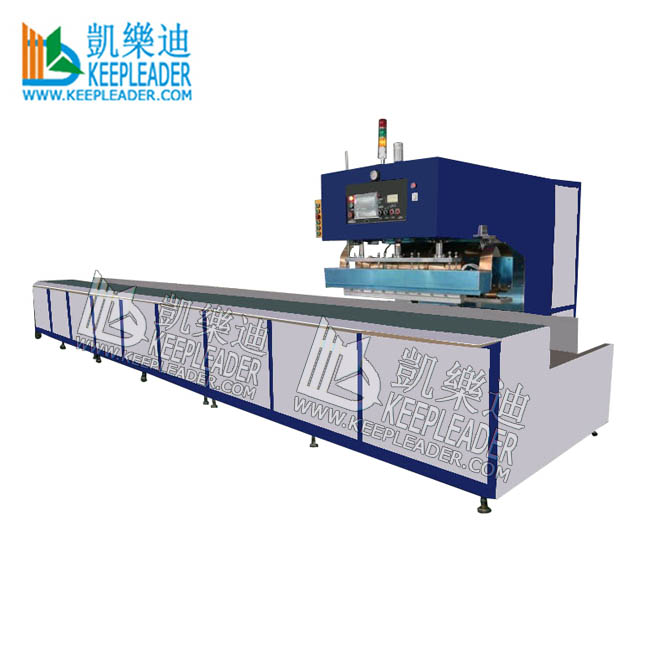

Automatic High Frequency PVC PU Welding Machine for PVC_PU_TUP Membrane Radio Frequency Welding of PVC PU Tarpaulin H.F Welding

Automatic High Frequency PVC PU Welding Machine

The most important factors influence Automatic High Frequency PVC PU Welding Machine: #1: electrical power #2: pressure applied #3: welding time #4: cooling time, Finding the optimal process parameters will depends on your specific equipment, the materials involve and the specific geometries including thickness and area to be welded, achieving optimal results is often an experimental process guided by experience, as a guiding rule, the thicker material and focus on short welding times you need, the stronger electrical power you need

Machine Description

01: Application

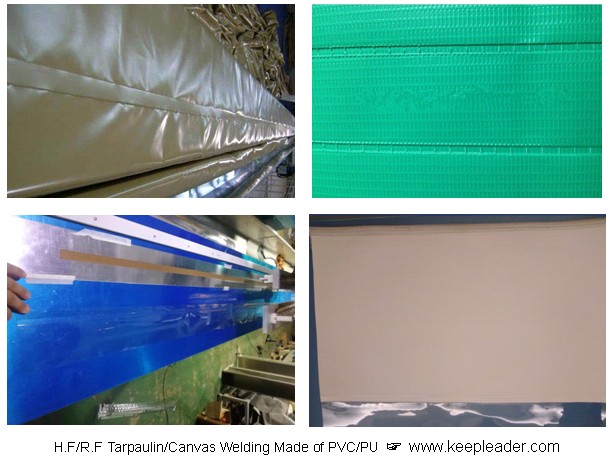

High Frequency PVC PU Welding Machine is the case of radio frequency welding (R.F/H.F bonding) for PVC PU TPU Membrane, the welding heat is produced by molecular oscillations (Friction heat) directly in the PVC, PU material to be welded, oscillation tube transmits the high frequency oscillation usually 27.12mhz and pressure to the welding tool (electrode), the pressed surface is the jointing area, where the molecules inside the PVC, PU material to start to move and generate heat which softens the material, No heat is applied from outside, it is generated inside the PVC,PU, After cooling the welded surface at a constant pressure, the material is fused and welding is ready, the weld joint can be as strong or even stronger that the surrounding material, high frequency welding is suitable for welding/making/sealing/bonding the membrane structure cloth/Film made of PVC, PU, TPU, PETG, other PET Family sheets. Even or Nylon, Textile cloth treated by High frequency (H.F/R.F) reactive Poly material, or adhesive glue Tarpaulin, Canvas, such as stretched ceiling, tents, inflatable pool/boat, truck covers, Biogas balloon/bladder, oil fence, advertising banners, Film screen, canopy, awning, marquee, curtain, swimming ring, air floating, inflatable water trampoline, inflatable water roller, inflatable castle, inflatable slides, inflatable water slides, inflatable water park, inflatable pool slides, inflatable bouncy castle, inflatable jump bed, advertising flexible banner

02: Parameter

Name | High Frequency PVC PU Welding Machine | |

Technology | Radio Frequency welding (R.F/H.F) | |

Working Mode | Automatic Travelling | |

Available material | PVC/PU/TPU or textile, Nylon with high frequency-activated adhesive (H.F/R.F reactive material) | |

Model | KLR-8KW-CB | KLR-15KW-CB |

H.F/R.F power | 8000w | 15000w |

Power Supply | Phase Voltage: 110v/60hz or 220v/50hz*3 phase | |

Power Input | 15KVA | 30KVA |

Rectifier | Silicon diode | |

Oscillation Tube | 7T69RB | 8T85RB |

Oscillation Frequency | 27.12MHz | 13.56MHz |

Pressure | Pneumatic (Equipped air compressor 2hp) | |

Stroke distance | 150mm | |

Table Length | 6 meters ~54 meters | |

Welding Time | 0~30 seconds | |

Electrode size | 800*25*50mm | 800*25*50mm |

Net Weight | 2600kgs | 2800kgs |

Standard equipment | ||

Name | Origin | Brand |

Air driven components | Taiwan | Airtac |

AC contactor | Japan | Omron |

Relay | Japan | Omron |

Electron Tube | Japan/China | Toshiba/Jingguang |

Time Controller | Taiwan | CKC |

03: Character

Using the latest High frequency Technology, the radiation emission is suppressed

Important components is purchased by audited vendors in compliance with international standard

The design and confirmation take priority in resulting a machine is durable, stable, safe

With big size, deep and long throat of material groove

Control by PLC human interface which is user friendly

VC adjustment by stepping motor makes power adjustment easy and highly accurate

Sensitive anti-flash unit to protect machine and electrode

H.F welding head is travelling on the table, which is driven by servo-motor and ball bearing rail

Welding speed: 5~10 meters per minute

Universal usage for seam welding made of PVC/PU/TPU Membrane

Laser guiding projector is visible for material poisoning in accurate guidance

Machine Uses

Automatic High Frequency PVC PU Welding Machine has advantages of welding effect: #1: Seal is fluid proof #2: Great shear tear-resistance #3:Non-wicking seam #4: Almost invisible seam

Our Company

Automatic High Frequency PVC PU Welding Machine is mechanical self-building, all of your professional proposals can be into our producing process

Packaging and Shipment

Automatic High Frequency PVC PU Welding Machine is installed, and packed in plywood case, So, it is ready to use once you receive the cargo

Contact Us

We welcome the opportunity to explain every last details and all of the options available in fact, and. won’t waste your time and ours, our goal is to educate our potential customers and let them make an informed decision, please contact KEEPLEADER for more info of Automatic High Frequency PVC PU Welding Machine

☺ Attn: Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone/Whatsapp: +86 13590415784

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com / https://www.hfwelds.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader