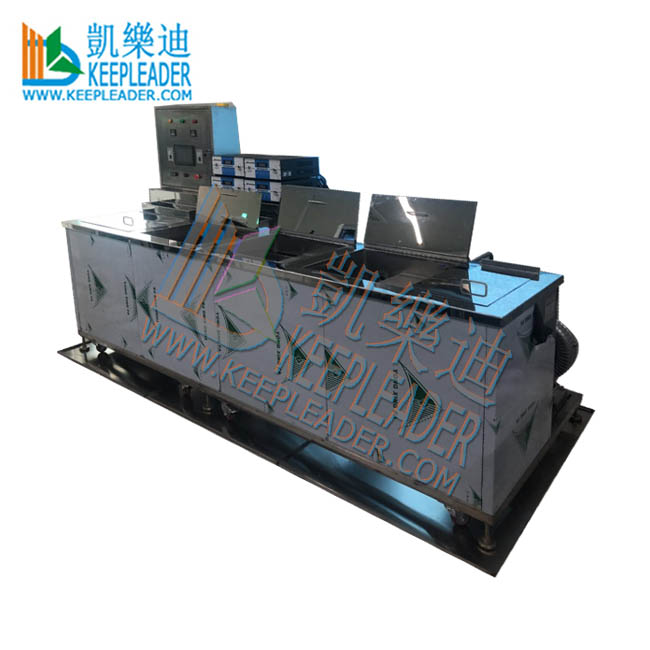

Multiple Tank Industrial Ultrasonic Cleaning Machine for Electronic Parts Ultrasonic Cleaning With Sonic Cleaning_Rinsing_Drying

Multiple Tank Industrial Ultrasonic Cleaning Machine for Electronic Parts

Multiple Tank Industrial Ultrasonic Cleaning Machine for Electronic Parts has function of ♦1: Dual Ultrasonic cleaning ♦2:Dural Rinsing ♦3:Hot Air Drying ♦4: Filter Circulation ♦5: Intermittent oscillation

Machine Description

Multiple Tank Industrial Ultrasonic Cleaning Machine for Electronic Parts

01: Parameter

Model | KLE-5024 |

Ultrasonic frequency | 40khz |

Ultrasonic power | 2400w |

Input power | 220VAC,60hz, or 380VAC, 50hz |

Tank material | 304 stainless steel |

Tank inside dimension | 400*600*600mm |

Tanks liquid dimension | 400*600*500mm |

Basket size | 300*500*500mm |

Fluid Operating temperature | 50~175 degree F |

Filter Cartridge flow rate | Up to 5GPM |

Filter cartridge size | Single 10”, 10 micron |

External Dimension | 5000*1300*1400mm |

Gross weight | 800kgs |

02: Application

Multiple Tank Industrial Ultrasonic Cleaning Machine for Electronic Parts is suitable for most five steps processing requirements inprecision parts, electronic components, power circuit board, electroniccomponents, surgical device, in five steps, the machine can have customizedconfiguration: Ultrasonic cleaning, rinsing, hot air drying, is deal forapplications that require zero-residue cleaning results and parts drying,

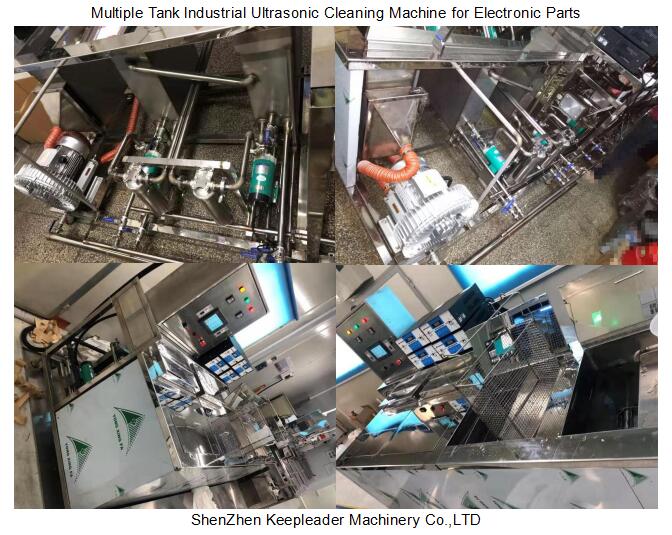

03: Tank details

Tank #1-2 are ultrasonic cleaning tanksusing two ultrasonic frequency generators with two changeable ultrasonicvibrators pad mount at two sides, tank has a weir flow system which utilizes adiverter bar and filtration pump along with a belt skimmer to improveefficiency of overall system, tank is heated using two heating elements, withfloat switch’s to ensure water level is correct for safe operation, each tankalso have separated filter circulation system and heating function

Tank #3-4 is dual-stage heated rinse tank,tank has a weir flow system which utilizes a diverter bar and filtration pumpalong with a belt skimmer to improve efficiency of overall system, tanks areheated using two heating elements per tank, with float switch to ensure waterlevel is correct for safe operation of heaters and filtration system, Tank #3-4 has an Auto-Fill valve tomaintain correct water level in tank. Tank also has rinsing basket and coverfor optimum performance.

Tank #5 is a forced hot air drying tank with integral duction and electricheat with blower package, tanks also have cover to assist in drying process

04: Machine process

Step 1: Ultrasonic cleaning with weir, oil removal Filtration andintermittent oscillation

Step 2: Ultrasonic cleaning with weir, oil removal filtration andintermittent oscillation

Step 3: Rinsing with Weir, oil removal filtration

Step 4: Rinsing with Weir, oil removal filtration

Step 4: Hot Drying

05: Character:

Eachtank of 2pcs ultrasonic cleaning and 2pcs rinsing has dripping platform

3-colorlight tower to indicate operating condition of system from a distance

PLCcontrol system on operation panel

5pcscleaning basket complied with working load

15kgsload capacity

Eachtank has filter circulation system to complete a whole recirculation and drainout the dirty liquid separately to avoid secondary contamination

Intermittentoscillation systems to oscillate parts during ultrasonic cleaning or rinsingcycles

Internallymounted components for cleaning exterior appearance

Easilyaccessible components facilitate maintenance operations

Tanks are fabricated using stainless steelfor superior corrosion resistance.

In addition, ball valves are used on drainand fill ports to facilitate the manipulation of liquids used duringprocessing.

06: Optional Equipment

Pump-Drain systems to pump liquids tooverhead waste or other location

Rinse water quality maintenance system

Ultrasonic rinse systems

Oil Skimmers

Spray rinse wand

Waste water evaporators

Closed-loop deionization systems

Machine Uses

Multiple Tank Industrial Ultrasonic Cleaning Machine for Electronic Parts has specified construction of tailored dimensional capacity and functional configuration to gratify individual cleaning process and purchasing budget

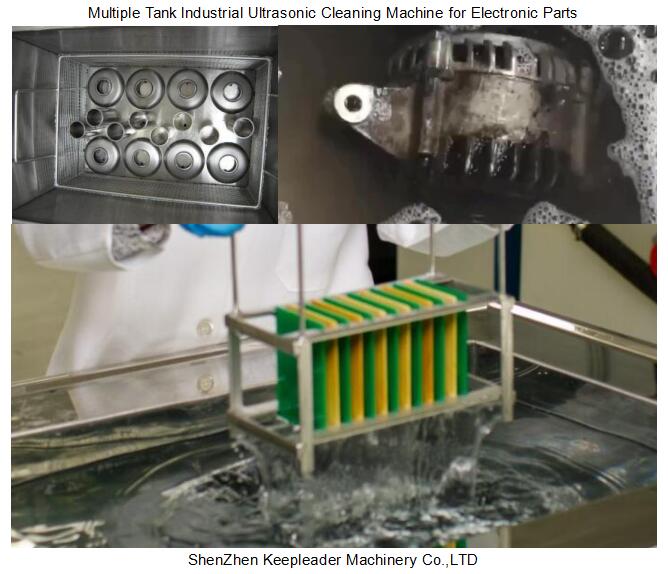

Detailed Images

Multiple Tank Industrial Ultrasonic Cleaning Machine for Electronic Parts has five tanks of configuration: ultrasonic cleaning_Rinsing_Hot Air drying_Intermittent oscillation_Filter Circulation

Functional Advantages

Multiple Tank industrial ultrasonic cleaning machine has Ultrasonic cleaning, ultrasonic rinsing and hot air drying, the whole process combined with dynamic flow combination, which is better coverage of component surfaces (minimizing standing waves and/or part shadowing) producing more consistent results and accelerated processing times, keepleader ultrasonic cleaning technology is offered in different sizes, weight capacities, and configurations (including automation) to accommodate a wide variety of applications

Spray cleaning and rinsing

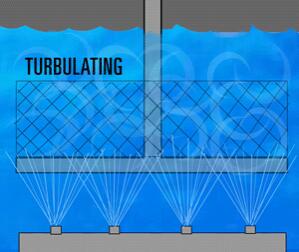

Combining platform oscillation with solution spraying under immersion, results in constantly changing flow patterns, keepleader spraying systems are proven to accelerate processing time

Ultrasonic cleaning and rinsing

Using platform oscillation to gently move parts throughout the ultrasonic working zone provides a superior cleaning action over conventional systems by moving the work through the peaks and nodes of the wave energy, ultrasonic cycles are sequenced with spraying cycles to further accelerate the process

Hot air knife drying

Using high volume hot air combined with changing air flow patterns created by the oscillating elevator provides accelerated drying cycles without excessive heating

Contact Us

Fore More information of Multiple Tank Industrial Ultrasonic Cleaning Machine for Electronic Parts, Please contact KEEPLEADER

☺ Attn:Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone/Wechat/Whatsapp:+86 13590415784

☎ Tel:+86 755 84190358

☞ Website:www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader