PET Blister Sealing High Frequency Welding And Cutting Machine for PVC PET Blister Package High Frequency Welding of Blister Welding

PET Blister Sealing High Frequency Welding And Cutting Machine

PET Blister High Frequency Welding And Cutting Machine Has customized creasing size, which depends on 5kw, 8kw, 10kw to 25kw,we also can mount automatid feeding stand for its auto produtction

Machine Description

PET Blister High Frequency Welding And Cutting Machine

Mainly application | |

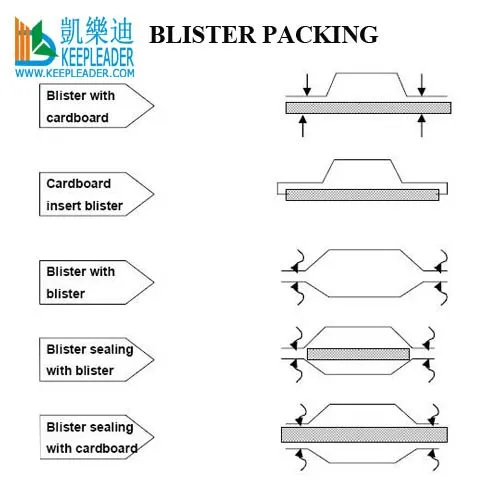

PET Blister Sealing High Frequency Welding And Cutting Machine Applied for double sides blister packaging for APET, PETG, GAG, PVC, welding and cutting of soft crease clear box making, toothbrush blister packaging, mobile clearer, belt, watchband, featured in automatic welding and cutting of blister packaging and paper card. | |

Character | |

Wide using in environmental protection plastic packing ,toothbrush packing, environmental production dress-glue products with APET,PETG,GAG clear plastic sheet or printing plastic sheet, Equally can process any materials needing welding and cutting simultaneously. double-way automatic slipway, back-forth or continuous delivering the mould, Accurate-orientation, error±20um. Adjustable cutting pressure 1-50 ton, stable and reliable in output, firm in structure. Adopting high sensitive anti-sparkle device NL5557 to avoid damaging the mould efficiency. Operation mode: oil pneumatic or pure-pneumatic PET Blister High Frequency Welding And Cutting Machine included one set of creasing and cuting mold/die/tooling | |

Technique specifications | |

Model | KLR-8000WT |

Power | 8000W |

Voltage | 220V/380V 50/60HZ |

Frequency | 27.12MHZ |

Input power | 15KVA |

Rectifier | SILICON DIODE |

Oscillation tube | 7T69RB |

Max pressure | 30T |

Gap between electrodes | 200MM |

active horn | 150MM |

Size of upper electrode | 350*500 |

Size of lower electrode | 350*500 |

Range of temperature | 30~200℃ Adjustable |

Welding time | 0~10S Adjustable |

Productivity | Equal or less 5000times/8h |

Net weight | 1.6T |

Overall dimension | 1920*1200*2060 |

MFR: KEEPLEADER™ have modified and designed model for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details, for PET Blister High Frequency Welding And Cutting Machine, pls tell us you material and its maximum crasing size

Detailed Images

PET Blister Sealing High Frequency Welding And Cutting Machine takes prominent features in #1: High Automation degree: auto turntable indexing with high frequency alternation; automatic robotic unloading device, auto loading paper card is available to combine a whole automatic production in blister packaging #2:Flexible operation: quick shift in auto and manual mode, close the automatic turntable, the working model also set manual stationary status as a free-standing model, touch screen is convenient accessed in setting, operation, reading with programmable logic control system #3: customized solution: support quick-changeover upper electrodes and bottom nests among different blisters/clamshell in shape and size, automatic feeding paper card and loading parts are acceptable in construction as per demands

Product Uses

PET Blister Sealing High Frequency Welding And Cutting Machine adopts HF welding principle, which designed mainly for paper card and blister sealing, double blister welding, blister packages are widely applied in blister packages bonding of hardware, stationary, toys, electron, cosmetic, lighten, Pen, socket, injection, battery, toothbrush, lipstick, automotive parts, household applications, healthcare, and medical products, high frequency can exert edge-trimmed sealing achieve a good appearance in clear packaging market, which also can improve not only protective but also advertising effect, the sealing width, pattern both are available in specification

Buying Guides

After-Sales Service

After purchasing at KEEPLEADER™ is first step of our after-service, all of machines at KEEPLEADER™ has one year guarantee, we provide free samples for defected parts to do replacement except for human damage, under information for your notice

01: KEEPLEADER™ always posts the new technical file in our homepage that can help our client in new technical information of machines’ design, character, application, operation, maintenance,

and related, KEEPLEADER™ also welcome our clients feed back the machines’ working condition that can get one to one service

02: If the machine you purchased has any defects, please contact sales representative at KEEPLEADER™, we will assign our experienced engineer analyze your case and provide technical support, in case of damaged parts that cannot repair, KEEPLEADER™ will provide a new parts to replace the defect

03: For any replacement and maintenance, KEEPLEADER™ has user manual and training video

04: KEEPLEADER™ can go to oversea for on-site training

05: KEEPLEADER™ can provide electric diagram if in need

06: PET Blister High Frequency Welding And Cutting Machine has one year warranty, we provide free parts for replacement and life-long technical support by paper solution and drawing for improvement and modification

Contact Us

PET Blister High Frequency Welding And Cutting Machine, pls contac Ms Helen by Email: sales@keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader