Electronic Parts Cleaning Ultrasonic Cleaner of Ultrasound Immersion Dual Tank with Up and Down Agitation_Filtering Circulation

Electronic Parts Cleaning Ultrasonic Cleaner

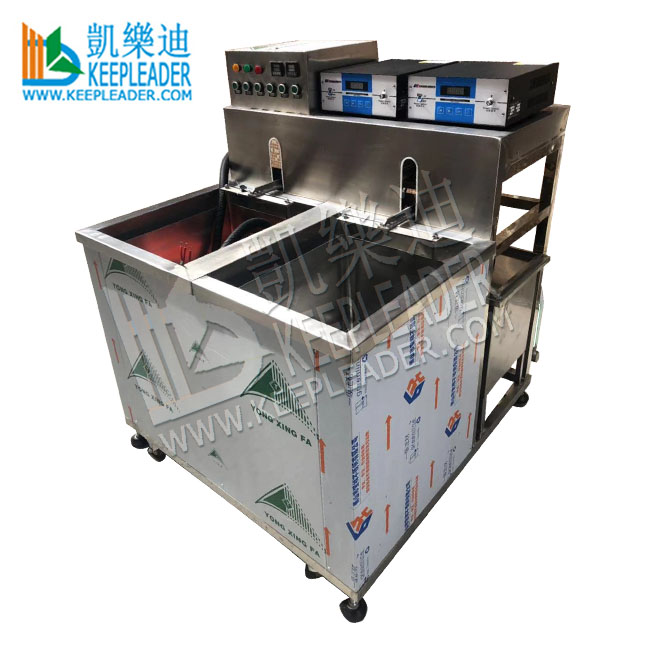

Electronic Parts Cleaning Ultrasonic Cleaner is dual tanks, automatic lifting and filtering circulation cleaning machine

Machine Description

Electronic Parts Cleaning Ultrasonic Cleaner

MACHINE INTRODUCTION

01:Introduction of Up and Down Agitating Ultrasonic Cleaning Machine with Filter Circulation

Electronic Parts Cleaning Ultrasonic Cleaner is using cavitations, acceleration, straight slow caused by ultrasonic applied to remove the dirty, residue and any contamination in dispersing, emulsifying, stripping force, equipped auto lifting can complete automatic loading and unloading cleaning parts, the slow pulling force can form a taking force to remove the detailed contamination from the cleaning parts easily, circulation and filtering system is another consideration in saving water consumption, avoiding secondary contamination

02: Application

Applied in the cleaning of semiconductor, silicon wafer, watch & clock parts, machine parts, engine parts, Filters, Jewelry, Glass, kitchenware, optical glass, electronics any other solid parts

03: Character:

Ultrasonic cleaning, auto lifting, slow pulling, circulation and filtering in one machine

Vibrators pack mounted at sides, or bottom

All is made of stainless steel, anti-corrosion, long-life span

Thermo-stat, digital display, and PLC operation interface

Ultrasonic intension can tune

Digital analog in matching, frequency seeping, intelligent ultrasonic generator

There is overflow slot at the tank top to avoid overflowing

Build-in input and output water valve, made of SUS304

Outside of cleaning tank is insulation treated

04: Cleaning procedures

Loading—cleaning basket immersing—ultrasonic cleaning/ cleaning basket auto up and down agitating—cleaning basket up—unloading

05: Main parameter

Model | KLE-1048RL | |

Ultrasonic power | 2400w | |

Ultrasonic frequency | 28khz/40khz | |

Heating power | 6kw | |

Pressure pump power | 2pcs*400w=800w | |

Driven motor | 400w~800w | |

Maximum Lifting weight | 500kgs | |

Auto lifting | 15~20pcs / minute | |

Material | Cleaning tank | SUS304,2B, T2.0mm |

Outside tank | SUS304,2B, T1.5mm | |

Vibrators pack | SUS316, T2.5mm | |

Frame | SIS202,T2.0mm, 60*40mm | |

Cleaning tank | two tanks of each size: 470*570*460mm | |

Overall size | 1400*1400*1600mm | |

Power | 380v/50hz, 3 phase, 5 wires | |

Total power | 9600kw | |

Net weight | 500kgs | |

Gross Weight | 600kgs | |

For Electronic Parts Cleaning Ultrasonic Cleaner, pls advise us keepleader

01: inner size of cleaning basket you want or you have

02: if you need up and down agitation?

03: if you need filter circulation

05: Maximum lifting weight

Detailed ImagesElectronic Parts Cleaning Ultrasonic Cleaner has advanced cleaning effects in #1: unmatched effectiveness #2: Speed #3: Cost Saving #4: Reduced downtime #5: Efficient removal of contamination within cavities #6: Detergent adding in ultrasonic agitation to remove special particulars

Machine Uses

Electronic Parts Cleaning Ultrasonic Cleaner can apply semi-automatic decontamination for electronic and automatic parts, medical components and other industrial cleaning, this ultrasonic cleaner constructs dual immersible tanks with auto lifting of up and down agitation and filtering circulation reservoir that can enhance washing efficiency and save the labor cost, tailored dimensional tank and specified functionality both are acceptable

Buying Guides

Electronic Parts Cleaning Ultrasonic Cleaner

What should be considered for ultrasonic cleaning machine in choosing?

01: The material of cleaning parts:

for the metal parts in cleaning, we need to classify iron, steel, stainless steel by its intensity, Chemical character, for the wooden, glass, optical glass, rubber, plastic and any other non-metal cleaning parts, their cleaning processes have big difference, So, their cleaning craft, cleaning procedures, cleaning solvent are all in need of pre-consideration

02: Surface condition of cleaning parts

Smooth surface have different cleaning method with rough cleaning surface, the cleaning effect also influenced, so, we need to consider the surface condition of cleaning parts in the cleaning procedures and method

03: Contamination status

The contamination of cleaning parts decide the cleaning solution, we usually calcify them into dust, oil, oxide, finger printer, Wax, and etc, the user should advise us all this information to manufacturer and chemical supply to get professional support, for example: for kitchenware in cleaning, the European countries always contaminate by animal fat, but, for Asian Countries the contamination in their kitchenware are often oil, starch, so, the cleaning method and solution have big difference

04: Cleaning effect in requirements

In cleaning effect, common metal parts and high precision electronic, surface rough treatment and precision machine are all have different requirements, so the cleaning method will be different, but, for the high demanded cleaning effect, the cleaning cost will be increased caused by its cleaning procedure and cleaning solution, this will be another consideration to balance every aspects

05: cleaning machine is its adopting

For multiple cleaning tanks, automatic transmitting, loading, unloading, auxiliary unit and etc are all have cost, so, the user should consider their budget on their cleaning process

06: Safety in choosing ultrasonic cleaning solution

The character of cleaning solution has big different, for ultrasonic cleaning , the solution must be water-based, nonflammable, skin friendly, non-toxic, also need to consider how to handle with the waste liquid, and local government’s rule in water recovery and recycle

07: Cleaning efficiency

The most important factor in choosing ultrasonic cleaning machine is hot to improve the cleaning effect, simple immersing can remove the contamination of metal parts, but, spend long time in emulsifying and dispersing, if the machine has lifting, and spinning function, will take the off-contamination away easily, if th machine have ultrasonic, the cleaning efficiency will be improved a lot, we also can build in circulation and filtering system, high pressure water spaying, hot air drying, automatic transmitting, loading, unloading, vacuum suction and etc

08: How to save the cost?

The user always can take some cleaning procedures before machine cleaning, example, can immerse the cleaning parts in advance, spay ultrasonic solution to emulsify and soft the contamination, consider manual cleaning and etc, that’s to say, if we adopt hand cleaning for heavy oil and hard contamination, and apply precision cleaning by ultrasonic cleaning machine, can save the cost

09: Automatic cleaning

Open style, single robot arm transmitting are always adopted for 5 cleaning tank or less, three minutes cleaning time or less, loading 100kgs or less, for mass cleaning, and heavy contamination, we should consider multiple cleaning tanks, and multiple robot arm transmitting, belt transmitting

For light contamination, low demand cleaning effect, and mass cleaning volume, we can use hanging and belt transmitting

Contact Us

For Electronic Parts Cleaning Ultrasonic Cleaner, pls contact Ms Helen by E-mail: sales@keepleader.com

Cellphone/Wechat/Whatsapp:+86 13590415784 or Tel: +86 755 84190358

Website: www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader