Solvent Vapor Degreaser Steam Cleaning Ultrasonic Degreasing Machine of Auto Metal Parts Industrial Ultrasound Vapour Degreasers

Solvent Vapor Degreaser Steam Cleaning Ultrasonic Degreasing Machine

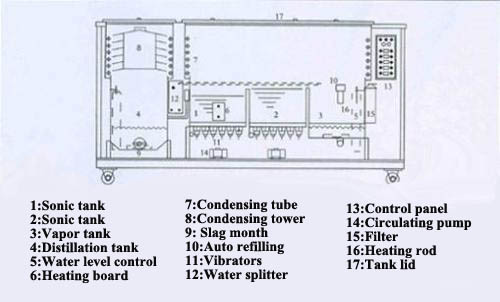

Solvent Vapor Degreaser Steam Cleaning Ultrasonic Degreasing Machine is a cleaning process in manufacturing that involves condensing solvent vapors on greased Auto metal parts, the whole cleaning process occurs in a machine chamber where a chemical solvent is vaporized inside, dissolving all oil and contaminants on the auto metal parts’ surface, as the auto metal parts in basket lifted out of the initial cleaning chamber, the solvent drips back into the boil sump, carry away all dirt and contaminants with it, after that, the auto metal parts in the basket is dipped into a second chamber, call the rinsing sump, where the remaining grease and residual are rinsed off with cleaning solvent, this Solvent Vapor Degreaser Steam Cleaning Ultrasonic Degreasing Machine of multiple stages comprises two ultrasonic agitation sump, both of them can apply rinsing and pre-cleaning, boiling sump achieves vaporized cleaning, and last procedure of distillation sump accomplishes solvent recirculating process, the operator can organize flexible procedures of cleaning in a whole machine

Product description

Solvent Vapor Degreaser Steam Cleaning Ultrasonic Degreasing Machine used for cleaning electronic components, the rosin of circuit board, heavy grease of precision mechanical parts, polishing wax, precision copper parts, aluminum zinc alloy, greasy hardware | |

Character | |

Imported vibrators IIE made in USA Stainless steel cleaning tank, SUS304,2.0mm for thickness Imported air cooling unit made in USA Other electronics, made in Japan or South Korea Build-in condensing system, fully enclosed, by which to avoid solvent evaporation Liquid level sensor and alarm system for ensuring the machine work properly Solvent filtration and recycling system reduce the production cost Fast drying system to improve efficiency Automatic temperature control system | |

Qualified Solvent | |

Trichloroethylene, methyl chloroform and other organic solvents (non-flammable solvent) | |

Cleaning process | |

First class ultrasonic cleaning→second class ultrasonic cleaning→vapor cleaning→cooling and drying (automatic distillation solvent recovery and automatic recycling) | |

mainly parameter | |

Ultrasonic cleaning tank ( fist class and second class) | |

inner cleaning tank | 300*320*340mm(L*W*H) |

Vibration mode | Bottom |

Vibrators number | 12pcs |

Ultrasonic power | 600w |

Ultrasonic frequency | 28khz |

Heating power | 2kw |

Heating mode | Heating board from outside |

Temperature | 0 up 100 |

Vapor cleaning tank | |

Inner cleaning tank | 300*320*380mm |

Heating power | 2kw |

Heating mode | Heating tube into the water |

Temperature | 0 up 110 |

Distillation tank | |

Inner cleaning tank | 300*320*390mm |

Heating power | 2kw |

Heating mode | Heating tube into the water |

Temperature | 0 up 110 |

Frozen system | |

power | 3HP |

Frozen height | 450mm |

Turns of frozen pipes | 10-3/4 |

General parameter | |

Overall size | 2230*660*1170mm |

Overall power | 11kw |

Power supply | AC380V,50HZ |

Product overview

Solvent Vapor Degreaser Steam Cleaning Ultrasonic Degreasing Machine utilizes the ultrasonic capabilities you’d expect, with modern emissions control ad safety precaution in place, most importantly, this appliance is thoroughly designed to not only operate efficiently,but also effectively handle a wide range of degreasing solvent that are available, multiple tanks arranged in one machine with top condensing chilling coil blanket, the cleaning in vapor zone achieve final precision cleaning and drying after firstly ultrasonic agitation rough cleaning and ultrasonic agitation rinsing, the side-along distillation tank takes capability of re-circulation of contaminated solvent, the oil-water separator and filtering pump are built in the plumbing system in continuous generating purified solvent

Detailed images

Solvent Vapor Degreaser Steam Cleaning Ultrasonic Degreasing Machine has conventional tech in industrial auto parts cleaning, but exceptional performance because of benefits in elements of #1: superior cleaning performance and effectiveness;#2: no dependence upon manual cleaning;#3: prevents cross-contamination;#4: repeatable;#5: quick, no extra drying process required proceeding with next production procedures;#6: recycle solvent from part to another;#7:compact structure in save footprint;#8: reliable and consistent cleaning effect

Buying guides

How doesSolvent Vapor Degreaser Steam Cleaning Ultrasonic Degreasing Machine work?

01:Solvent degreasing

Involves the exposure of a work piece to pure solvent vapors released by a boiling solvent, the work piece is usually suspended in the vapors just above the boiling solvent, when the warm vapors touch the comparatively cool work piece, a condensing action occurs which dissolves the contamination and flushes it away as it runs off the parts, this cleaning action will continue until the work piece and the solvent vapor are the same temperature,

Beyond this basic procedure a number of additional cleaning operations are often used, including immersion rinsing, ultrasonic cleaning, spray under immersion, and part agitation, the degreaser styles depicted here can operate with n-propyl bromide, chlorinated solvents,

02: Degreasing applications

Although water-based cleaning systems are effective in many applications, some aspects of aqueous-based cleaning can make it impractical or unusable for certain cleaning application, solvent degreasers are used for removal of petroleum based oil, grease, wax and other stubborn solvent-soluble soils from nearly any non-porous surface, they are also very effective at precision-cleaning highly sensitive parts contaminated with dust, fingerprints, and other air-borne contaminants, vapor degreasers are commonly used to clean, machined parts, electrical and electronic subassemblies, intricate metal and plastic components, artificial joints, lenses, and a wide variety of other products prior to further processing, assembly, inspection, or packaging, nearly any part can be cleaned in a solvent degreaser without concern for quality control issue like part oxidation, effective drying, and water spots, because no water is used in the process

Safety control and solvent retention systems

All solvent degreasers depicted here are designed to meet or exceed the latest EPA guidelines for

03: Safety and solvent retention

031: Safety controls

Every style includes safety interlocks which interrupt the machine’s operation if the system runs low on liquid, high on vapor, or if the temperature in the cleaning compartment rises significantly above the boiling point of the solvent, additionally, power to the spray pump will be interrupted if the vapor level drips by more than four inches

032: Solvent retention systems

One of the prime objectives in degreaser-design is solvent efficiency, retaining the vapors within the machine is important for worker safety and economic operation; several factors effect the overall efficiency of system:

033:The primary cooling system:

A multiple pass perimeter cooling coil is used as a heat exchanger to condense the vapors, creating a sustainable vapor zone, the primary coil must be maintained at a temperature that will cause the vapors to readily condense, this function can be performed by directly refrigerating the coils, or by

passing the chilled water through it

0331:On refrigerated machine:

On systems with integral refrigeration, a direct-expansion refrigeration system is attached directly to the primary cooling coil, the refrigeration system operates continuously, removing the precise amount of heat required to ensure proper vapor condensation

0332: On water-cooled machine:

On water-cooled vapor degreases, a coolant flows through the primary cooling coil, if a constant supply of cool water is available, the machine can operate on water along, more commonly however, to save water and to assure constant temperature, a combination of coolant and water is circulated through a refrigerated water chiller, the water chiller may be dedicated entirely to one degreaser, or it many be serving the cooling requirements of other equipment simultaneously, water-cooled degreasers that are connected to a water chiller perform as efficiently as refrigerated machine

034:Secondary cooling system:

The secondary cooling system consists of an additional cooling coil that is mounted directly above the primary cooling coil and maintained at sub-zero temperatures, creating a cold blanket of air which further reduces solvent consumption, EPA guidelines call for freeboard chiller on vapor degreasers containing trichloroethylene, perchloroethylene, or methylene chloride, given that a properly-designed freeboard chiller will reduce evaporative losses by 30% to 45%, the cost of a freeboard chiller can easily be justified as solvent-saving measure with a short payback period, regardless of whether the degreasing fluid is a chlorinated solvent or a nearly developed fluorinated solvent

035: Freeboard ratio:

Freeboard is the area within the machine above the vapor zone, the freeboard ratio compares the with of the of the top opening of the machine to the freeboard height (the height of the area above the top of the vapor zone, higher freeboard ratios have been demonstrated to aid in solvent retention, all standard KEEPLEADER vapor degreasers includes freeboard ratios between 1:1 and 1.25:1, freeboard ratios between 1.25:1 and 1.5:1 are offered to customers

036: Drop-seal cover:

Unlike common sliding covers that leave gaps around their perimeter, this unique cover is designed to roll into place and seal the work chamber from the atmosphere, virtually eliminating evaporative losses during downtime

Contact Us

Solvent Vapor Degreaser Steam Cleaning Ultrasonic Degreasing Machine comes in a variety of configurations depending on customer application, keepleader, we can size a solvent vapor degreaser to fit not only your parts, but also you cycle time and production requirements, with today’s solvents it is essential to size the vapor degreaser properly to ensure solvent recapture through distillation cycle chilling coils, for expert help with your precision cleaning application, look to keepleader, our applications engineers can work with you to get a solvent vapor degreaser that not only fits your part, but also you cycle tie and production, requirements, contact a solvent vapor degreaser expert to receive a free proposal

☺ Attn: Ms Helen

✉ E-mail: sales@keepleader.com

☎ Cellphone/Wechat/Whatsapp: +86 13590415784

☎ Tel: +86 755 84190358

☞ Website: www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader