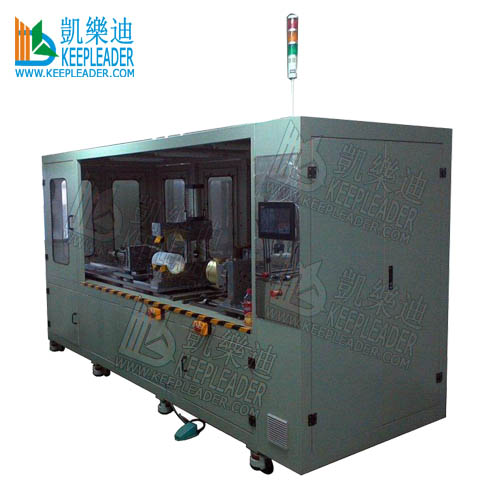

Horizontal Heat Press Melting Welder Hot Plate Welding Machine of Float Ball_Air Filter_Oil Tank Butt Thermal Bonding Equipment

Horizontal Heat Press Melting Welder Hot Plate Welding Machine

Horizontal Heat Press Melting Welder Hot Plate Welding Machine earn its gratification in performance because of prominent salient, such as: rugged welded steel tube frame;separated pressure controls for melt and seal; unique rack system coordinates tool platen motion in horizontal axial loading;optional activation in servo or pneumatic impeller; programmable logic control with touch screen interface with all digital timing; manual-close and auto-open door, door closure initiates cycle; fully adjustable hot plate carrier, fully enclosed cabinet with exhaust fans to drain out possible fume,mechanized fixture or vacuum part retention system both are available

Product description

Horizontal Heat Press Melting Welder Hot Plate Welding Machine

01: Parameter

model | KL-5060H |

power | 20KW |

voltage | 380V/440V |

Air pressure | 0.5~0.7MPa |

Ambient humidity | ≤80% PH |

Air tube diameter | Φ12 |

weight | 850KGS |

Size | 1500*1025*1900 |

Working area Productive | 500*600 2-5pcs/min |

Pressure | Air pressure |

02: The application of hot plate welding

The ideal assembly solution for medium, contoured, or complex thermoplastic parts, is hot plate welding, designed for versatility and easy tooling changeover to accommodate a variety of parts, typical hot plate welding application include fuel tanks, reservoirs, taillight lenses, and vent ducts, hot plate welding easily achieve hermetic seals, and welding strength approaching that of virgin material

03: What is hot plate welding?

Hot plate welding is widely used for most challenging materials, and large part assembly with high strength and hermetic requirements, during hot plate welding, both part halves are held rigidly in position against/near a thermally heated platen to melt the joining surfaces, the materials are then quickly separated from the heated source, driven together and allowed to re-solidify under pressure

Vertical or horizontal platen hot plate welding configurations are available, from manual loaded and unloaded machines to semi and fully automated in-line systems, offers the widest array of standard products designed to accommodate a most product sizes

Hot plate welding machine is generally loaded manually with an automatic welding cycle, although automatic loading is possible in certain applications, this machine is a standard horizontal hot plate welding machine with an automatic loading cycle, and the particular hot plate welding machine can make to order

04: Features of hot plate welding

Rugged welded steel tube frame

All-pneumatic operation

Unique rack system coordinates tool platen motion

Touch screen interface with all digital timing

Full enclosed cabinet with exhaust fans

Interior work light

Numerous large access doors with keyed hardware

Pneumatic system to lockable cabinet

Separate pressure controls for melt and seal

Vacuum part retention system

05: Advantages of KEEPLEADER Hot plate welding

According to the products, choose pneumatic, hydraulic or servo motor drive

Control mode by Siemens, PLC, touch screen entry, Achieve manual and braking control

Moulds mode: they are made of cold and hot moulds, which can be designed by buyer’s welding parts structure

Such parameters can be adjusted as welding temperature, heating time, cooling time, welding depth, vacuum retention time, pressure, transferred time

According to the requirements of the welding procedure, choose manual or full-automatic mode

Can design the fixture according to the products

Suitable for welding HDPE, PP, PE, ABS, PVC and so on

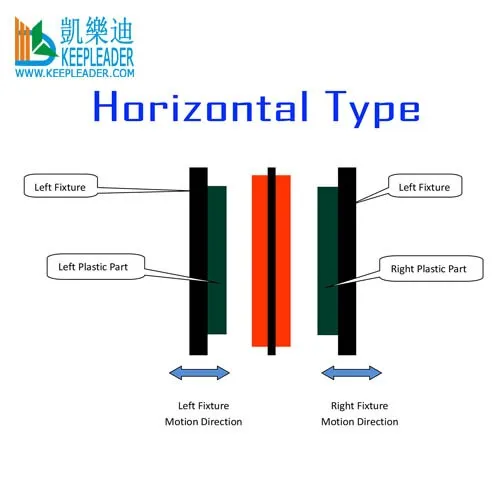

06: Vertical VS. Horizontal platen systems;

Vertical | Horizontal |

Easy to manually load both part halves positively into the tooling, ensuing precise, repeatable alignment during welding | More difficult to manually load both part halves positively as access to upper tool can be ergonomically challenging |

Not ideal when internal commentary is loose inside the part halves prior welding | Ideal system for part designs where internal components are loose inside the lower part half prior to welding |

No simple option for operator to load part halves outside the machine | Allows option of manually loading part halves outside the machine (requires drawer load and automatic top-half part pick-up) |

No special location feature need to designed onto the part halves or tooling for accurate alignment | Requires special location features be designed into molded parts themselves or the tooling (increases tooling cost/complexity) when using automatic top-half parts pick-up) |

Faster tool changeover that most horizontal machines offered today | Slower tooling changeover typically |

More complex to automate (often requires robotic action) | Very easy to automate when optional drawer load and automatic part drop to conveyor belt is used |

Not ideal for automatic part drop (onto conveyor belt after welding) | Allows easy automatic part drop onto conveyor belt after welding (when equipped when optional drawer load) |

Twin motion (Left and right) fixture allows independent control of force/speed on each part half. Both against heat platen and against each other | Single Motion (upper only) fixture allows independent control of force/speed of upper part half only |

07: Hot plate welding process

Step one: Part halves are placed onto and securely gripped by precision holding fixtures which insure adequate support and accurate alignment of the part halves throughout the hot plate welding process

Step two: to heat the part joint area, a thermally heated platen is placed between the part halves, the holding fixture close to compress and melt the part halves to be welded against the platen, displacing material at the joint area only

Step three: Compression and material displacement continue until precision hard-stops built onto the tooling are met, thermal heat continues to conduct into the material even though compression and displacement have stopped

Step four: after the joint area reaches molten temperature, the holding fixture open and the heat platen is withdrawn

Step five: the holding fixture then close, forcing the two parts together until hard-stops on the holding fixture come into contact one another

Step six: when cooling is complete, the gripping mechanism in one of the holding fixture releases the part, the holding fixture open and the finished part may be removed

KEEPLEADER existing line of hot plate welding is extensive, vertical or horizontal platen welding configuration are available, from manually loaded and unloaded machines to semi and full automated in-line systems, each of KEEPLEADER hot plate welding is designed to accommodate specific range of application requirements

Function uses

Horizontal Heat Press Melting Welder Hot Plate Welding Machine can get better performance basing on six welding parameters that govern the hot plate welding process,that is vital in gaining a gratified effect, which includes bear up time or bead size,heat soak time,dwell time,cooling time,heating pressure and cooling pressure and temperature,1st:the bead up time is the time taken to achieve a minimum size bead around the perimeter of the component,this time will depends upon the wall thickness of component being welded, the thicker the wall, the longer it will take to achieve the minimum bead size, a typical minimum beard size will be between 1 to 2mm height;2nd:the heat soak time is the length of time the component remain in contact with the hot plate under axial load, this is again dependent upon the wall thickness of the component, the thicker wall of component, the longer the required hot soak time, longer heat soak time will be needed for materials with higher melting temperature;3rd:the dwell time is the that taken for the components to be removed from the surface of the hot plate, then brought into contact with each other, once the components are removed from the hot plate their surface begin to lose heat, it is , therefore, essential that the dwell time is keep as short as possible to prevent the surface cooling to below the temperature required for welding before being brought into contact;4th:the final welding parameter relating to time is the cooling time, this is amount of time that is the components remain under an axial load after they have been brought together before they are removed from the holding fixture, during the early stages of this phase, the thermoplastic molecular chain at the weld interface can diffuse to form the weld;5th: the heating and cooling pressure is the pressure at the component interface during the the welding process,in the welding of injection molded components, it is recommended that melt stops are used to control the displacement of material during the heating and cooling phases, in this case, the heating and cooling pressure is not critical to the welding process providing it is greater that the value required to push the parts against the melt stops;6th: the welding temperature is the temperature at which hot plate is set in order to carry out the welding process, this is typically 60 to 100 degree above the melting temperature of the material. If the melting temperature is set too high, it can lead to degradation of material at the weld interface, which will result in a poor quality weld

Product uses

Horizontal Heat Press Melting Welder Hot Plate Welding Machine is a thermal welding technique of producing strong, air-tight welds in thermoplastic parts, that adopts pneumatic or servo motor activate axial loading,but the basic principle is traditional, thermal energy in a tightly controlled manner is localized a the perimeter of joining around to achieve melt and solidified bonding process,thermoplastic parts can be heated molter temperatures very quick and then joined together, large injection-molded plastic parts get hermetic butt sealing, our existing line of hot plate welding machine is extensive, vertical or horizontal platen welder configurations are available,each of them is designed to accommodate a specific range of application requirements

Contact Us

KEEPLEADER’s Horizontal Heat Press Melting Welder Hot Plate Welding Machine is an ideal assembly solution for medium or large contoured thermoplastic parts, designed for versatility with easy tooling changeable to accommodate variety of parts, particularly for the top half of welding object inside core must be entrapped during sealing to the other half, our technique team will evaluate your house mounting to resolve the problem that is encountered with vertical heat press melting welder hot plate welding machine,actually speaking, not only consider its axial loading but also its fixture and fixture alignment in precision control, believe that our practical success on thermal melt welding can awake of your evaluation in detectable comparison,let start a collaborative journey from you concept to an achieved machine

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader