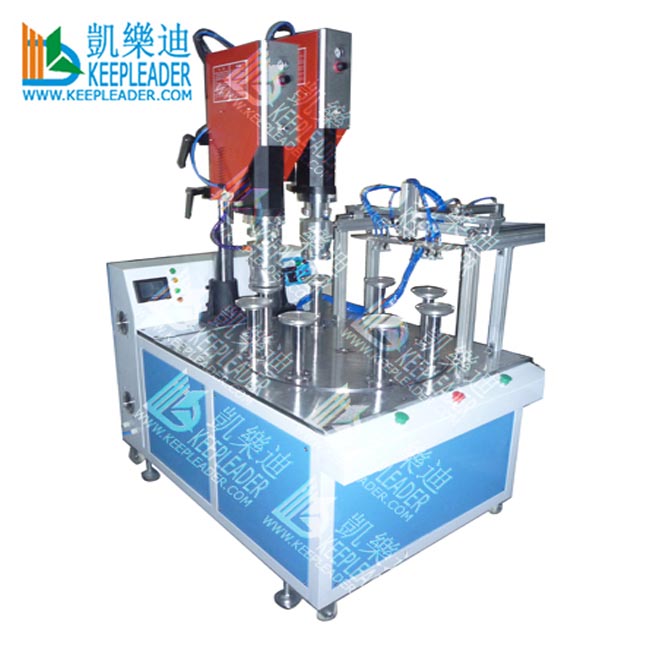

Plastic Cylinder Box Making Bottom Sealing Ultrasonic Welders of PVC_APET Cylindrical Boxes Turntable Ultrasound Welding Machine

Plastic Cylinder Box Making Bottom Sealing Ultrasonic Welders

Plastic Cylinder Box Making Bottom Sealing Ultrasonic Welders is fast and efficient technique that creates a strong, clean and hermetic seal,which increasing production without compromising quality, it is used for packaging, medical device and other specialized applications that required high quality seal, ultrasonic welding plastic achieve quick bonding with any consumable material, likely adhesives, bolts and any other chemical agent,hence, we adopts ultrasonic bonding on transparent packaging of plastic cylindrical box making in bottom mounting sealing, no scratch occurs results in a aesthetic appearance to catch eyes, this advanced welding technology helps you meet environmental goal by increasing respectability

Product description

Plastic Cylinder Box Making Bottom Sealing Ultrasonic Welders

Plastic Cylinder Box Making Bottom Sealing Ultrasonic Welders to make plastic box | |||

Characters | |||

IC circuit precision control, automatic overload protection system | |||

Mainly parameter | |||

Model | KLC-2615TD | KLC-3215TD | KLC-4215TD |

Input power | 2600w | 3200W | 4200W |

Frequency | 20KHZ/15KHZ | ||

Input voltage | 220V | ||

Max input power | 1.2KW | 1.9KW | 2.3KW |

Active horn | 70mm | ||

Oscillation system | Auto-stimulating | ||

Output time | 0.01-99S | ||

Pressure | Pressure bound 1-7bar | ||

Welding area | 200mm*8 | 220mm*8 | 250mm*8 |

Compressor | 1HP | ||

Net weight | 200kg | 250kg | 300kg |

MFR: KEEPLEADER™ have modified and designed Plastic Cylinder Box Making Bottom Sealing Ultrasonic Welders for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

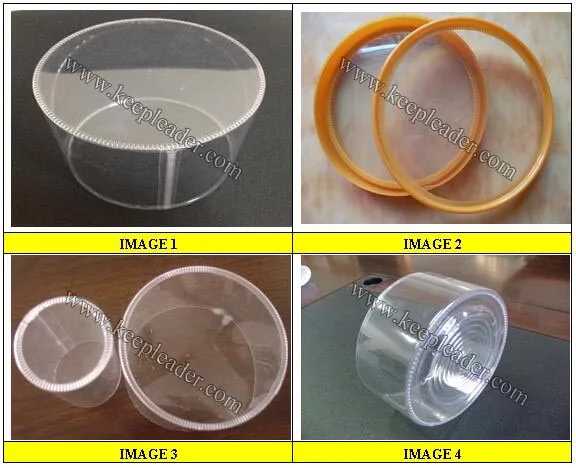

Detailed Images

Plastic Cylinder Box Making Bottom Sealing Ultrasonic Welders can complete crucial step of bottom assemble bonding in cylinder container making,that is made of PVC,APET,PETG, ultrasonic welder integrates automatic turntable indexing increases productivity, ultrasonic frictional bonding can save the cost, because its sealing process is quick achieved by material matrix without consumable material, likely fasteners, adhesives and cementing, the melting design of cross-line results in water-proof sealing performance, which is optimal solution in making cylindrical containers, the machine supports quickly-interchanging molds for versatile sizes production, solely one operator can complete the cycle process without time and quality compromising

Product uses

Plastic Cylinder Box Making Bottom Sealing Ultrasonic Welders are applied for welding bottom of plastic cylindrical box made of PVC,APET,PETG, cylinder box is combined transparent packaging solution, that is mounted with tubular container, box lid and bottom, this ultrasonic welder is capable for bottom sealing, its rotary table indexing can increase the productivity in continuous loading material and unloading finished box, the produced cylindrical containers are prevalent in packaging field of candy, gift, toys, stationery, umbrella, fishing tools, crisp food and fashion food and etc

After-sales service

After purchasing at KEEPLEADER™ is first step of our after-service, all of machines at KEEPLEADER™ has one year guarantee, we provide free samples for defected parts to do replacement except for human damage, under information for your notice

01: KEEPLEADER™ always posts the new technical file in our homepage that can help our client in new technical information of machines’ design, character, application, operation, maintenance,

and related, KEEPLEADER™ also welcome our clients feed back the machines’ working condition that can get one to one service

02: If the machine you purchased has any defects, please contact sales representative at KEEPLEADER™, we will assign our experienced engineer analyze your case and provide technical support, in case of damaged parts that cannot repair, KEEPLEADER™ will provide a new parts to replace the defect

03: For any replacement and maintenance, KEEPLEADER™ has user manual and training video

04: KEEPLEADER™ can go to oversea for on-site training

05: KEEPLEADER™ can provide electric diagram if in need

Contact Us

Plastic Cylinder Box Making Bottom Sealing Ultrasonic Welders is our universal model of ultrasonic welder with auto turntable index, that is applied in bottom sealing of cylinder box making,keepleader, we strive to improve productivity in a reliable solution and affordable price, ultrasonic welders are used in welding process of making plastic cylinder boxes, that is creative construction, attaining possibility improves your company’s efficiency by learning from our experienced engineer and getting hands-on training of fundamentals of ultrasonic welding technique in transparent packaging application, favor you can bestow your productive concern during procurement, that is guiding criteria in working out our outstanding solution

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader