Clear Cylinder Box Making Bottom Sealing High Frequency Welding Machine of PVC_PET Cylindrical Container Packing Boxes HF Welder

Clear Cylinder Box Making Bottom Sealing High Frequency Welding Machine

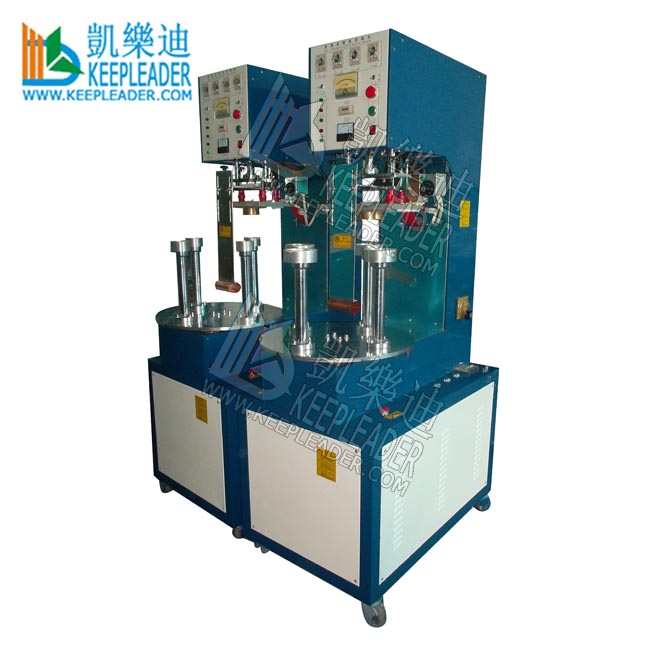

Clear Cylinder Box Making Bottom Sealing High Frequency Welding Machine is our 5kw high frequency welder of standing-along, that is used for plastic cylinder box bottom sealing in PVC_PETG cylindrical conainter making, its construction of automatic turntable indexing can improve production efficiency and save labor cost, one operator can complete the whole cycle production in continuous loading and unloading without interruption

Product description

Application | |

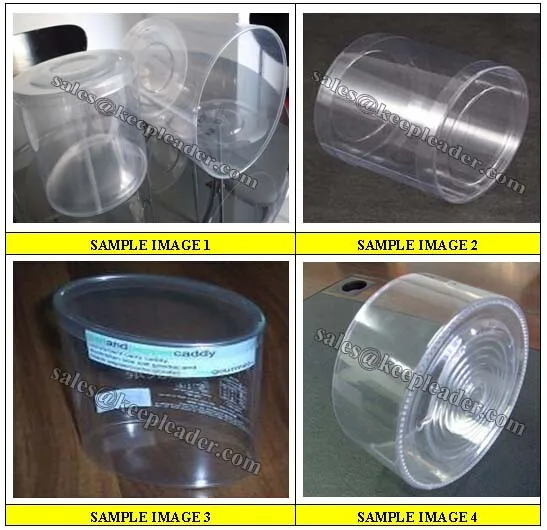

Clear Cylinder Box Making Bottom Sealing High Frequency Welding MachineUsed for welding/sealing clear/transparent cylinder bottom(cylinder and disk), which is made of PVC,PETG, APET and PP by high frequency welding machine or ultrasonic welding machine, APET and PP is no ok for high frequency welding | |

Product Features | |

High Q value oscillation tube, stable and reliable for output the welding diameter is optional, 30mm up to 300mm qualified for different length of clear cylinder high frequency welding is stronger and beautiful for welding effect The machine is turntable feeding, automatic and manual operation is optional High sensitive anti-sparkle device NL5557 to avoid damaging the mould. High quality imported apparatus European-model high frequency vibration box, more reliable and stable in output High precision cam splitter for precision counterpoint Fully enclosed for operation position(optional) Mounted five caster with four brakes Automatic thermostat to keep the temperature at best performance in welding High precision high frequency knob for visible control Low voltage control panel for safe purpose Anodized mould and tooling for longer life span Top amounted cylinder for vertical pressure, which is more uniform Foot pedal control and button control is optional Over current protection circuit to avoid burning out the oscillation tube | |

Technique Specifications | |

Model | KLY-5000W |

RF power | 5kw |

Voltage | 220V,380V,50hz or 60hz |

Frequency | 27.12MHZ |

Electronic power | 8KVA |

Rectify | Silicon diode |

Oscillation tube | 7T85RB |

Max gap of electrode | 200mm |

Stroke distance | 175mm |

Size of upper electrode | 200*350mm |

Size of bottom electrode | 400*600mm |

Temperature | 30 up to 200 degree |

Welding time | 0 up to 10 seconds |

productivity | 4000/8hours |

Overall dimension | 1000*660*1730mm |

Standard equipment:

Name | Origin | Brand |

Air driven components | Taiwan | Airtac |

AC contactor | Korean | LG |

Relay | Japan | Omron |

Electron Tube | Japan | Toshiba |

Time controller | Taiwan | CKC |

please contact KEEPLEADER for more info and tech assistance, KEEPLEADER has modified and designed Clear Cylinder Box Making Bottom Sealing High Frequency Welding Machine for our customers' unique and special requirements

Detailed Images

Clear Cylinder Box Making Bottom Sealing High Frequency Welding Machine perform bottom sealing in cylinder contaimer packaging, that is third steps in cylindrical box making, they are 1st: cylinder tube forming; 2nd: cylinder edge curling; 3rd: bottom sealing, the last production is cylinder lid making, that is freely-arranged, because of cylinder lid is a separated item in assembing cylinder box packaging

Contact Us

Clear Cylinder Box Making Bottom Sealing High Frequency Welding Machine is high frequency dielectric sealing technique used in cylindrical box bottom sealing, that can adopt ultrasonic bonding, depends on the material, size and preference, usually, PVC,PETG is better for high frequency welding, but ultrasonic welding is capable for all thermoplastic, likely PVC, PETG, APET, PP and etc, these machines all can integrate autoamtic production with robotic arm to achieve auto loading material and unloading finished products, our tech team can work with concerns to offer reliable and affordable machine for your individual production in transparent cylinder box packaging

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader