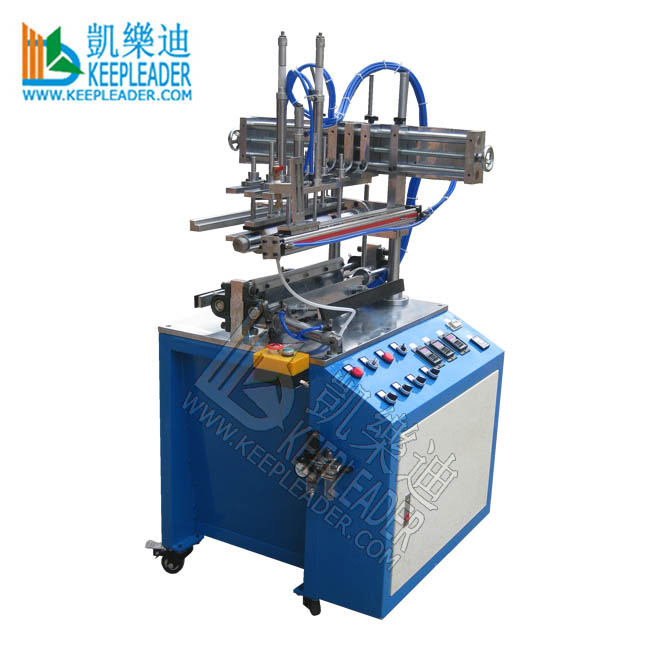

Plastic Cylinder Box Making Cylindrical Tubes Forming Machine of Semi-Automatic Wrapping_Folding Transparent Round PVC_PET Boxes

Plastic Cylinder Box Making Cylindrical Tubes Forming Machine

Plastic Cylinder Box Making Cylindrical Tubes Forming Machine is used for making tubes of clear or printed cylinder box made of PVC, PETG, APET, Semi-automatic process of manual loading and unloading, auto wrapping and gluing or bonding, is taken into flexible production

Product description

Plastic Cylinder Box Making Cylindrical Tubes Forming Machine

01: Application

Plastic Cylinder Box Making Cylindrical Tubes Forming Machine is semi-automatic packaging box cylinder making machine, suits for all kinds of PVC, PET, APET,PETG,PC Cylinder box, clear cylinder gluing, roundish box side gluing, packing cylinder box side sealing/bonding/cementing, transparent cylindrical box packaging has popularity in packing candy, gift, toy, stationery, umbrellas, packing gear, badminton, snack food and other daily necessities, but only for making cylinder packages body, must combine with other processing machine for the completed production such as edge curling, box lid and bottom making, and bottom bonding, anyway, keepleader can provide one-stop service in supplying all of relative machines to satisfy your practical production with specified construction

02:Parameter

Name | Plastic Cylinder Box Making Cylindrical Tubes Forming Machine |

Model | KLY-200D |

Voltage | 220v,50hz or 110v,60hz |

Heating Power | 1500w |

Ultrasonic Power | 3200w |

Control System | Siemens PLC |

Pneumatic | 3~6kgs/cm2 |

Cylinder Diameter | 45~200mm |

Cylinder Length | 15~350mm up 460mm |

Sheet Thickness | 0.18~0.55mm |

Bonding Process | Gluing or ultrasonic welding |

Productivity | 12~14pcs / Minute |

Suitable Materials | PVC,APET,PETG,PC |

Weight | 280kgs |

Dimension | 800*700*1700mm |

03: Salient Features

Advanced tech of spray gluing to take cosmetic bonding appearance without bubbles, white dots

The spraying speed and scales are adjustable in precision control to achieve clear bonding performance

Programmable logic control with touch screen is convenient and readable in setting parameter

Pneumatic and electronic components is complied with international standard

The triggering system is optional between pedal valve and auto timer control

Adopt glue storing jar to apply spraying pressure to coat even and strong bonding process

Machined mechanical components in precision to achieve perfect alignment in whole process

Detailed Images

Plastic Cylinder Box Making Cylindrical Tubes Forming Machine is semi-automatic cylinder tube forming in making cylindrical box, which is auto gluing the laminated seam after wrapping, will combine with edge curling, lid and bottom making machine in the whole production, we integrate ultrasonic friction heat bonding seam into auto cementing process as extra option in flexible production

Product uses

Plastic Cylinder Box Making Cylindrical Tubes Forming Machine takes semi-auto process in cylindrical box wrapping when making clear/transparent or printed cylinder box, auto folding the sheets into round to next procedures of gluing or ultrasonic welding overlap seam, which is favored for flexible production with interchangeable mandrels to satisfy various length and diameter of transparent/clean or printed cylinder box, which is cost-efficient and favorable packaging in field of industrial components, cosmetic, stationary, daily necessaries, health care, slid food packaging

Contact Us

Plastic Cylinder Box Making Cylindrical Tubes Forming Machine will combine with other processing machine in the whole production of making plastic cylindrical box, such as, bottom and lid making machine, bottom sealing/welding/gluing machine and edge curling machine, all of them respectively have their differences in details, our consideration in option is just to satisfy each individual production with flexibility, reliability, consumption, efficiency and productivity, please don’t hesitate to afford your preferred salient characters that we will do for you, believe that our experienced staffs can work out a reasonable solution for your practical manufacturing

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader