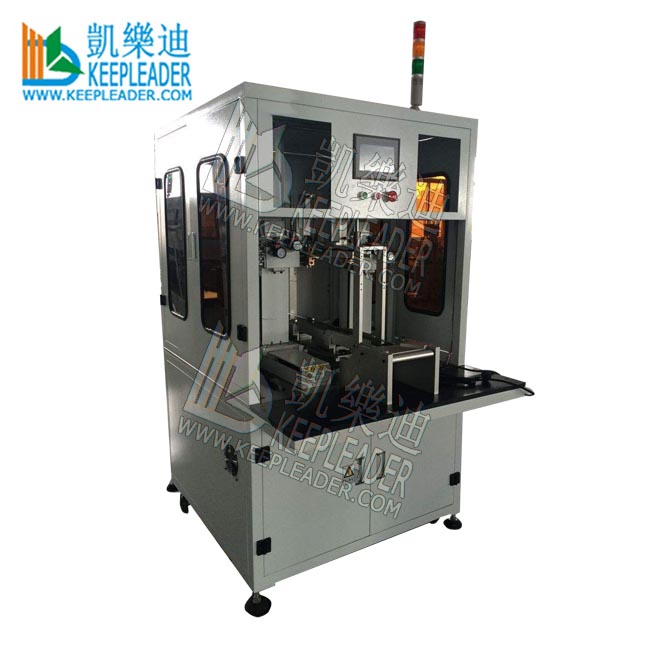

Cylindrical Battery Cell Welding DC Spot Welder of Automatic_Dual Sides_18650 Lithium Batteries Pack Inverter_Resistance Welders

Cylindrical Battery Cell Welding DC Spot Welder

Cylindrical Battery Cell Welding DC Spot Welder is mainly used for 18650 battery pack tab welding at two sides configured with automatic X,Y Axial feeding index, the adjustable power scale can varies different welding thickness within 0.3mm basing on splitting sheet and projection point, this DC spot welder adopts dual pulse welding, the first pulse is used to the battery surface coating and oxide removal, and the make the contact place in welding electrode produce slight deforming,improve the effective contact area, the second pulse is used to ontology metal welding,can effectively promote the quality of welding and reducing welding spatter

Product description

Cylindrical Battery Cell Welding DC Spot Welder

01: Parameter

Model | KLM-500 |

Driving Power | 500w (except for welding power) |

X axis | 520mm (20pcs 18650;16pcs 26650) |

Y axis | 320mm |

Maximum loading | 200pcs 18650 |

Tolerance | 0.05mm |

Power supply | 220v±10%, 50Hz±10% |

Driving Current | 6A (except for welding power) |

Welding current | 9950A |

Air tube | 6mm inner diameter, 8mm out diameter |

Air pressure | 0.4~0.6Mpa |

Air exhausted | 0.110L/S |

Net weight | 500kgs |

Overall size | 1150*1350*1755mm |

Welding Speed | 0.5s/point, 3200pcs/h |

Maximum speed of motor drive | 1000mm/s |

Working temperature | -10~40 degree |

Working humidity | 20~90% |

Life span | 5 year+ |

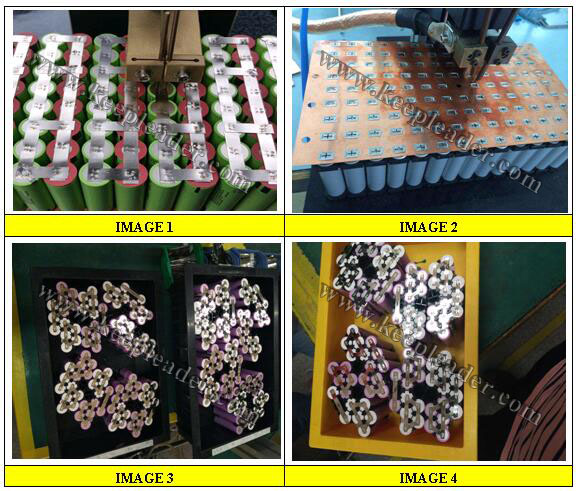

02: Application

Automatic battery pack spot welder is professional welding machine to make battery pack using 18650, 26650 battery cell in automatic loading and unloading, it can weld both sides together at high speed,

03: Features

031: Have manual model and automatic mode

032: Auto-checking and alarming of miss welding, false welding weak welding, and over welding

033: Built-in PLC, which is visual and touch screen in programming

034: Automatic alignment and correction

034: Welding current monitoring system can read in resetting

035: Alarming system can remind working status of auto parts, welding, current, position and etc

036: Adopting Panasonic Servo system

037: TBI wire rod and THK Guide (or same grade)

038: SMC cylinder, solenoid valve and filter

039: OMRON and Panasonic sensor

0310: Adopt USA technology, can weld 0.3mm thickness Nickel sheet

0311: National standard Aluminum 5015 and 3061 components

Detailed Images

Cylindrical Battery Cell Welding DC Spot Welder gains gratified selection among the competitive market in battery pack assembling process, likely, No.1:capacitors transformer, DC output heat concentration, the heat efficiency is increased, the welding process is stable and welding quality is improved and the electrode life is prolonged;No.2:high speed and high precision microprocessor control to provide highly stable repetitive welding with current monitoring function;No.3: programmable Logic control with touch screen;No.4: high speed welding: a quick start and high polarity switching reduced the temperature effect so that make the welding surface clean and beautiful;No.5:polarity switching:suppression of asymmetrical results makes the two points welding strength uniform and extends the service life of the electrode;No.6: the machine adopts IBGT or capacitors discharged power transformer to warranty the welding quality and welding speed, non ordinary welding machine can compared with it;No.7: Double pulse can reduce welding spatter, effectively improve the quality of welding;No.8: programmable logic control with touch screen, the user can store the practical programs of qty: 168 for referential selection;No.9: welding voltage locking technology to prevent net voltage fluctuations to affect the welding current

Product uses

Cylindrical Battery Cell Welding DC Spot Welder construct X, Y auto feeding mechanism of servo-motor indexing, that drive the cylindrical cell plate to localize the bonding position after precise alignment, spot welding process can automatically complete the cylinder batteries tap spot welding in array and roll line feeding, this dual pulse,programmable logic control, capacitors discharged spot welder of automatic feeding is used for 18650, 21700,26650,32650,32700 cylinder battery pack automatic spot welding, it can weld both side simultaneously with high speed and prominent effect and the highly automated human-machine interface make it easy to operate it, it can be used in electric tool battery, torsion car battery, energy storage battery pack, scooter electric vehicle battery and etc, the operation and debugging very easy and convenient, design of components built-in makes appearance more concise

Contact Us

Supposing that you are a newcomer to the field of battery building, it can be challenging to find the best Cylindrical Battery Cell Welding DC Spot Welder for battery pack assembling, this is compounded by the fact that different batteries for different application have varying needs in terms of what type of spot welder is used for the job, our Cylindrical Battery Cell Welding DC Spot Welder is dual pulse spot welders of automatic feeding in execute spot welder at two sides of batteries in battery pack assemble,keepleader, we construct tailored compatible configuration and maximum loading size and proposed controlling system for versatile productions, from your concept to ultimate production, our expertized working team can provide you with a reliable solution at affordable price, don’t hesitate to consult with them to find what more they can do for you, we are ready for listening your concerns

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader