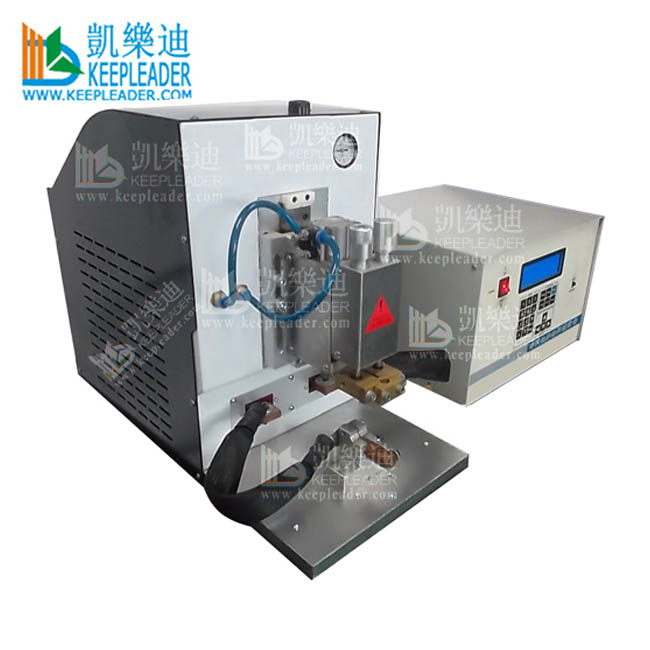

Battery Pack Welding Dual Pulse DC Spot Welder of Capacitive Discharge_ Lithium 18650_26650 Cells Tab Soldering Inverter Welders

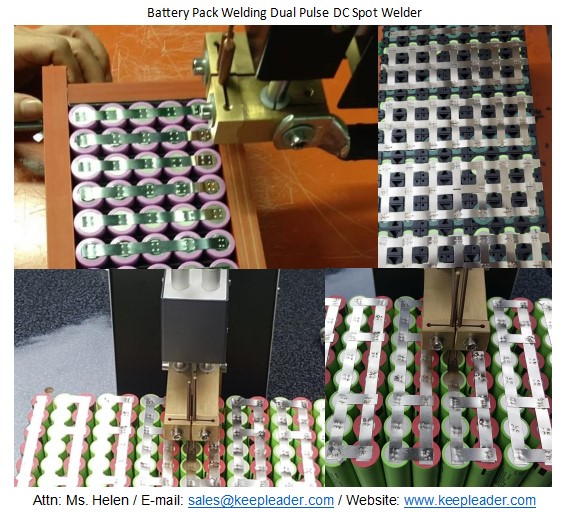

Battery Pack Welding Dual Pulse DC Spot Welder

Battery Pack Welding Dual Pulse DC Spot Welder is used for high quality welding, there are two pulses for every actuation of the welder,the first pulse is small fraction of the total pulse energy,it has the ability to clean the area to be welded by giving it a quick heat pulse, evaporating surface water vapor, oil, oxide and other contaminants, it also establish a good, high conductivity area for the second, or welding pulse, the second pulse fuses the two pieces together, the area of weld is very small, that piece remains cool, and the electrical conductivity and strength are high because the two piece are alloyed over the spot surface,the method of Battery Pack Welding Dual Pulse DC Spot Welder is particularly good for welding batteries, wires, jewelry, steel, stainless steel, chromium and other passivated surface, in addition, capacitive welding has the advantage of quich energy release and manageable energy input, this means that welds occur fast enough that spot are small and high very small heat effected zones, the welder can be operated on standard household voltage and powers,battery manufacturers require spot welders for tab welding and battery pack assembly, this tabletop Battery Pack Welding Dual Pulse DC Spot Welder is ideal for batteries packs and tabs and contacts

Product description

Battery Pack Welding Dual Pulse DC Spot Welder

wire spot welder of dual pulse, capacitive discharge | |||||

Application | |||||

Communications equipment: battery combination, cell phone batteries, cell phone hardware Electronic Components: CRT devices, sensors, resistors, fuses, semiconductor components Appliance: metal piece to fix, heating piece Automobile making: flashing lights, relays, filaments Digital Products: laptop computers, digital cameras, MP3 batteries, computer memory heads and so on. electromechanical devices: contactors, circuit breakers, motors Metal Products: medical equipment, lamps, badge, headdress, jewelry and other aerospace, Precision metal parts, instrument, metal connectors, sensors, etc | |||||

Character | |||||

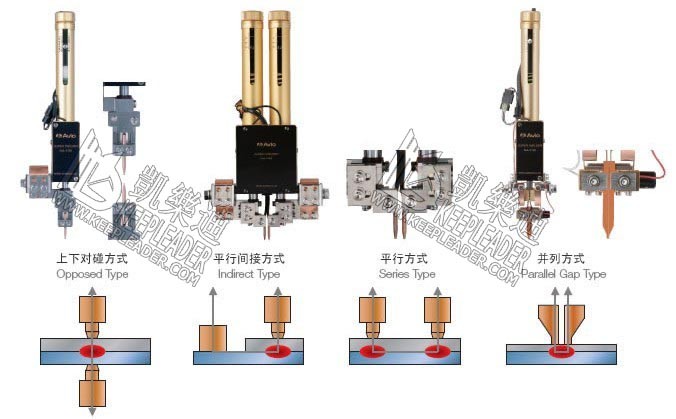

(single) double AC pulse energy storage welding, which is reliable for welding result CPU control, high definition LED display 240*64, the operation is visual and be more precision 128 user-defined welding procedures, all of them can be locked by manager State locking technology, which can avoid false triggering The unit can integrated into automatic production line Can set pedal switch to detect the welding parts before power generating Can set prepressing time before power discharge Radio (RFI) and electromagnetic interference (EMI) protection Power box and welding section are separated, which is safer Pneumatic and pedal control in one machine, which is more flexible Discharge time can be set between pulse 1 and pules 2 long, medium and short-pulse adjustable to fit fine welding | |||||

Mainly parameter | |||||

Rated power: 3.0 up 500watts/second (joule), the display screen can show the whole (maximum) energy percentage (%), the tolerance is 0.5%, the display screen is 0.1% up 0.5% in required energy Stability of power box: changes in the nominal voltage supply of +/- 13%, the power box can keep the voltage of capacity band at set value of +/-0.25% Display screen: the display screen adopts 240*64 high definition LCD, is visible for debugging Capacitor control circuit: when the voltage of error amplifier is over the required value to cut off charging circuit, one resistor connects at two sides of capacitor bank, by which let the voltage of capacitor bank work at required level, the dead zone of capacitor control circuit is about 0.6% of maximum voltage Line fault step-down: the is for safety purpose, when the power supply cut off suddenly, one resistor of voltage step-down automatic connects to release the power of capacitor bank Ignition circuit: Ignition requires an external account is closed or low-touch control logic circuit, inside filtering device can prevent electrical interference (RFI) triggered over ignition Power supply: 220v, AC, 50/60HZ, 2635watts rechargeable, 35wattes as spare, When 230V, 2A Cutout Welding ignition lock: error amplifier output, when charging and discharging to prevent ignition circuit, which is helpful to prevent to ignition before capacitor charging and discharging, the welding ignition lock circuit can prevent defected welding effect Programmable Prepressing time: combine with ignition welding head in the manual and automatic working mode without welding pressure, guarantee electrode is positioned well with welding parts before welding energy outputting, the prepressing time can be programmable (range:0.1 up 9.9 seconds) remote program selection: four monopole input: remote selection1-128 procedure; remote to prevent capacitor bank charging, when do remote program, the operation panel can be instead Valve drive output: can control electromagnetic valve of pneumatic welding head, 24VAC, 15A output Output pulse characteristic: at the side of power output, multiple a non-inductive load of 0.01 ohms, at both ends of it to measure pulse characteristics, to measure the rising time between zero amplitude and maximum point, to measure the pulse width at 10% amplitude point | |||||

Pulse transformer | Capacitor bank | Rising time | Pulse width | Pulse amplitude | |

Multiple(short) | 12000mfd | 9.1ms | 2.0ms | 11.5v | |

series(long) | 12000mfd | 16.5ms | 3.7ms | 7.8v | |

Welding speed: how many piece can be welded per minutes average when the machine work at rated status, | |||||

Maximum energy percentage | Repeated welding Nos/minutes | Interrupted welding Nos/minutes | |||

2% under | 116 | 170 | |||

25% | 78 | 80 | |||

50% | 51 | 55 | |||

100% | 27 | 30 | |||

Specifications | |||||

Model | KLM-875 | ||||

Rated power | 3.0-875w/s | ||||

Drive Form | Pedal | ||||

Welding Current | 0-99 Adjust | ||||

Electrode Diameter | optional | ||||

Input Power | AC220± 10%/50Hz | ||||

Welding Power | DC | ||||

Electrode Travel Length | 15mm | ||||

Max Welding Thickness | 0.8mm | ||||

Overall dimension | 310mm*280*430mm | ||||

Net weight | 60kgs | ||||

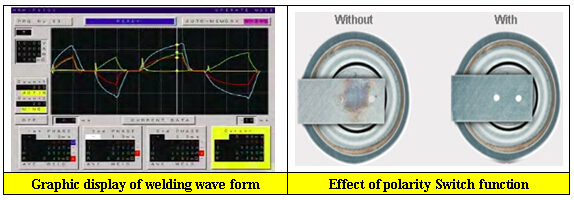

Technology illustration

Battery Pack Welding Dual Pulse DC Spot Welder provides strong, clean, repetitive welds, the first pulse heats the welding surface to eliminate contaminants and to seat the welding electrode tips, the second pulse hen performs a strong spot weld, this method is considered to avoid spatter and avoid possibility of weak welds, the heat generated in the smallest contact at quickest alloyed docking,the programmable logic control integrated with touch screen is accessible for resetting parameter and monitoring current, voltage and graphic reports, this process is designed specifically for battery pack spot welding

Product uses

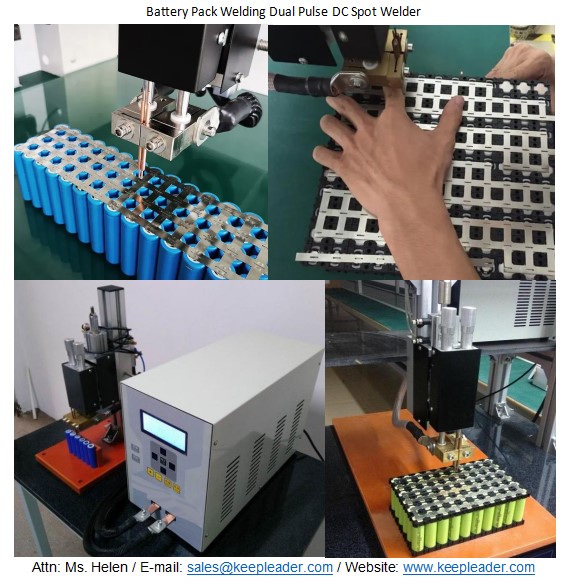

The wide scales of application for Battery Pack Welding Dual Pulse DC Spot Welder mainly concentrate in electronic assembling field of power storage supplying, likely battery pack process welding, thermocouple process welding, automotive application of welding, copper, brass, and aluminum thin sheet weld, cross wire welding process, honeycomb tacking and resistive other applications

Buying guides

Capacitive discharge spot welders at low price for high quality

Overview of DC capacitive discharge spot welder

The latest spot welder introduced a high-frequency resistance spot welding for high-end needs of clients this spot welder is microcomputer control and AC-DC resistance sticks, single phase or dual pulse, capacitive discharge or transform discharged spot welding; the spot welders have wide scope in application at KEEPLEADERTM, under examples for reference

01: All kind of steel lithium battery assembly

02: Aluminum lithium battery assembly, aluminum lithium-ion battery composite film of Nickel and aluminum welding

03: Nickel plate and Nickel plate connection, Nickel plate and the battery connection

04: Lithium-ion batteries and Nickel plate copper connection

05: All kinds of button batteries and Nickel plate welding

06: welding thin button cells will not have depression, yellow, black phenomenon

07: Ni-MH battery assembly

08: All the old batteries repeat the spot

09: Various hardware components of the welding

10: Foam Nickel, then precision hardware side access

Single and dual pulse versions

This spot welder has fine spot welder power sources allow you the versatility to take on welding from the large all the way into the micro-scale! KEEPLEADERTM spot welder gives good repeatability by displaying the exact energy readout of each weld, purchase a hand weld tool or weld heads to meet your welding requirements

The features of Capacitive discharge spot welders at KEEPLEADERTM

01: inexpensive, capacitive discharge, power source single or dual pulse versions available

02: Adjustable weld energy/power, dual pulse systems have adjustment for energy for both pulses, in addition, the dual-pulse feature can be turned off.

03: weld energy indication

04: optional pen, battery tab and manual or pneumatic plug-in weld heads

05: standard foot switch

06: microcomputer control, visible and stable output, dual-pulse welding that can do pre-welding, pre-solder oxide removal, remove debris, reducing the spark, continued welding to ensure a solid solder joint appearance, no black, spot size of the uniform burr, does not affect the appearance of the welding appearance

07: with the traditional exchange pulse, capacitive discharge spot welder, welding time is very short on the intrinsic properties of the batteries had no effect, does not affect the battery internal resistance, change does not affect the voltage and capacity, but not to cell performance impact

After completion of the weld surface of the battery is more clean, burr is small, not yellow, and not black

08: the microcomputer control precision: long-term, high-speed scanning micro welding in the input voltage, the power of a wave, the calculation of compensation data immediately change the welding energy, so that the welding does not occur due to voltage fluctuation in the fire bombing of weld or phenomenon, to ensure that each welding effect consistent, and welding sparks small, minimal impact on the battery, almost none

09: the operation set simplification: new panel design, the use of aluminum and metal buttons, durable, micro-computer of the parameters, the use of LCD liquid crystal display, keyboard adjustment, accurate intuitive ,convenient and more humane

10: Adjustable and easy to use, the new electrode design, solder pin spacing, pressure independently adjustable, for the original welding, alignment accuracy, high yielding,

11: sale low maintenance, easy maintenance, as the machine most of the use of imported components, to ensure low failure rate, and the spot welder structure design, maintenance, replacement of only one integrated circuit board, the general mechanics can be replaced

12: with automatic alarm and cut off the system, if the spot welder is damaged, will automatically display failure, and cut off the welding circuit to prevent the failure to expand, and to remind the repair

13: automatic counting, one output can be automatically counted 0-9999 facilitate the calculation of daily production

14: import solder pins: unlike ordinary welding ring used in further processing of the material to be shaped, which KEEPLEADERTM uses imported high-quality special welding products welding pins. And other three sets of import and distribution of each welding machine needle

A note about dual-pulse, capacitive discharge technology

Dual pulse spot welding is used for high quality, precision welding, there are two pulse for every actuation of the welder, the first pulse is a small fraction of the total pulse energy, it has the ability to clean the area to be welded by giving it a quick heat pulse, evaporating surface water vapor, oil, oxides and other contaminants, it also establishes a good, high conductivity area for the second, or welding pulse, the seconds pulse fuses the two pieces together, the area of the weld is very small, the piece remains cool, and the electrical conductivity and strength are high because two piece are alloyed over the spot surface, the spot welder at KEEPLEADERTM is passed SGS audited

Dual pulse, capacitive discharge spot welder is particularly good for welding batteries, wires, jewelry, steel, stainless steel, chromium and other passivity surface, so far, most of spot welder at KEEPLEADERTM is applied in field of battery spot welding

Capacitive welding has the advantage of quick an stable energy release, and manageable energy input, this means that welds occur fast enough that spots are small and have very small heat effected zones, KEEPLEAERTM adopts made-in-Japan capacitors that has better performance and life-span

The welder can be operated on standard household voltage and powers

Battery pack/cell manufacturer/builder require spot welders for tab welding and battery pack assembly, this small battery terminal welder is ideal for battery packs and tabs and contacting sheets

Dual pulse industrial spot welders of KEEPLEADERTM

01: Dual pulse operation removes surface inconsistencies

02: Dual pulse operation removes surface inconsistencies and contaminants

03: Adjustable pulse width, much more finesse that transformer based welders

04: Available 125, 250, 500 and 875 Joule (125, 250, 500 and 875w a second)

05: Adjustable from 1% to 100% energy discharge

06: Up to 600 welds/min

07: Simple, user-friendly interface, potable size

08: Perfect for battery pack assembly

09: Hi Visibility display shows weld parameters

This dual pulse, capacitive discharge spot welders are easy to use as well as powerful, CD (capacitive discharge) spot welder is a version of resistance fusion welding that offers high peak currents with extremely fast pulse rise times and short durations (on the order of 10’s of microseconds), the short pulse lengths and high current allows the welding of high conductive materials, including copper, and brass, welding current and pulse widths may be adjustable to weld more resistive materials such as steel, and Nickel, capacitive discharge welding produces repeatable welds, independent of local line voltage variations and is capable of extremely fine energy adjustment, the dual pulse weld setting helps eliminate surface inconsistencies, contamination and allows adjustment of the initial contact of the welding electrodes to produce repeatable effects

KEEPLEADERTMcan make modification on our current design to satisfy special requirements in diversity, welcome to filed inspection

Packaging and shipment

Battery Pack Welding Dual Pulse DC Spot Welder is arranged shipment in 1 plywood case for transportation, that is 100% ensured for safe conversion

Contact Us

Battery Pack Welding Dual Pulse DC Spot Welder has many advantages over other welder types, likely DC power supply of controlled power energy, computerized programmable logic integrated touch screen for convenient resetting and monitoring condition, dual pulses welding of one clean the contamination, seat the electrode tip and other one complete the ultimate welds without spatter in result strong welding, capacitive discharge power transformer to store and release weld energy, you weld energy will be highly repeatable and will not affected by line voltage fluctuation, you can also achieve quick energy release for welding highly conductive metals such as copper, this quick energy release is concentrated into a small area, generating only on a small heat signature or heat affected zone, consult these salient characters or more introduction with our tech team to find what more we can do for your business

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader