Handheld Plastic Spot Welder Gun Ultrasonic Welding Machine of 500w_28khz PP_PETG_ABS Bonding Cold Pressure Soldering Equipment

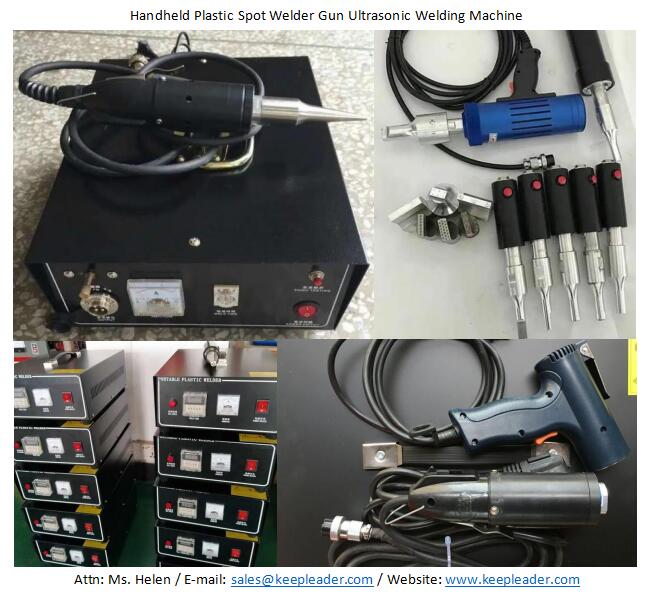

Handheld Plastic Spot Welder Gun Ultrasonic Welding Machine

Handheld Plastic Spot Welder Gun Ultrasonic Welding Machine takes compact design of ultrasonic generator, that integrates handgrip to execute reshaping,deforming,bonding, staking, riveting, swagging and other associated application for thermoplastic assembling process, its ultrasonic frequency usually adopts 28khz, this high frequency signal are produced by ultrasonic generator, then, converts to hand-holding vibration stack, and goes out from tip of ultrasonic acoustic tool with mechanical vibration, which is applied to the joining area,through the working surface and the intrinsic inter-molecular,the friction causes the temperature to be transmitted to he interface to rise,when the temperature reaches the melting point of work-piece itself, the work-piece welding port is rapidly melted, and then filled in the gap between he interfaces, when the vibration stops, the work-piece is simultaneously cooled and fixed under a certain pressure to achieve the perfect welding, this is basic principle of ultrasonic spot bonding, and other ultrasonic assembling process adopt the similar ultrasonic tech of cold coagulation happen basing on mechanical vibration melting criteria

Product description

Mainly Application | |

Handheld Plastic Spot Welder Gun Ultrasonic Welding Machine is used for Spot welding, riveting, screw imbedding, appliqué welding, often used in the field of stationery industries, consume electronics industry and electronics industry | |

Introduction of Ultrasonic handhold welder | |

Handheld Plastic Spot Welder Gun Ultrasonic Welding Machine is applied for plastic welding process, like, ultrasonic ABS welding, ultrasonic Acrylic welding, ultrasonic PVC and ABS welding, ultrasonic PA welding, ultrasonic PC welding, ultrasonic PE welding, ultrasonic pp welding, ultrasonic PE welding, ultrasonic PP welding, ultrasonic PS welding, ultrasonic PVC welding. | |

Characteristics | |

1.Proprietary anti-corrosion technology, even in the harsh acid salt (such as electroplating factory) working environment, the service life of up to ten years. | |

Advantages | |

1:low power consumption, firm welding, low noise, small-sized, dust-proof, high performance 2:automatic frequency-tuned system: take PLL for the ultrasonic circuit control 3: with pedal switch to convenient control 4: compacted, space-saved, convenient to transport | |

parameter | |

Model | KLC-3028/KLC-5028/KLC-8028 |

Power | 300w,500w,800w |

Voltage | 220V/50Hz 110V/60Hz |

Output Frequency | 28kHz/35kHz/40kHz |

Cohesion Specification | 1-15mm |

Cooling mode | Fan cooling |

Working mode | Separated excited |

Volume | 268*168*198mm(L*W*H) |

Net weight | 7.5KG |

Gross weight | 10kgs |

MFR: KEEPLEADER™ have modified and designed Handheld Plastic Spot Welder Gun Ultrasonic Welding Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

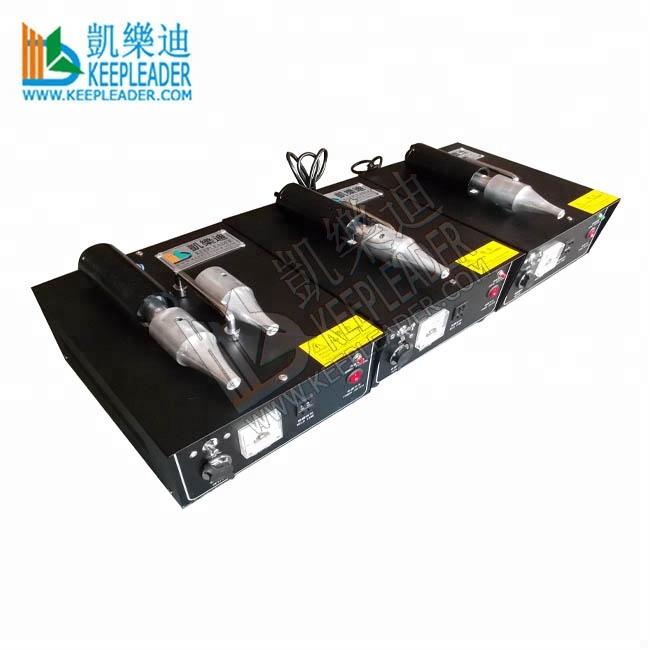

Detailed Images

Handheld Plastic Spot Welder Gun Ultrasonic Welding Machine is an assembly technique for joining two thermoplastic components as localized points without the necessary for preformed holes or energy director, plastic spot welder produces a strong structural weld and is particularly suitable for large parts, sheets of extruded or cast thermoplastic and parts with complicated geometry and hard-to-reach joining surface and maneuverable on-sites assembling process

Machine Uses

Handheld Plastic Spot Welder Gun Ultrasonic Welding Machine takes convenience for thermoplastic assembling process with features of ultrasonic vibration melting,maneuverable working-site and handheld welding application,strong power,good stability and flexible operation in a variety of application,such as spot welding, cutting, crew inserting,riveting, swagging, staking,inlaid and screw inserting into plastic hole and etc, low power consumption, firm welding, low noise, small size and dust-proof, high working efficiency, in addition, the ultrasonic acoustic tooling sets are interchangeable, they are compatible in versatile application whatever gratify sizes, shapes, patterns and geometry configurations

Ultrasonic sonotrode

Handheld Plastic Spot Welder Gun Ultrasonic Welding Machine has customized acoustic tooling sets, that is tailored with dimensional geometry, shape and pattern for respective thermoplastic assembly process, hence, we request you to provide the requirements,such as material, thickness, and sample photos to be welded, and we will configure the welding head for you

After-sales service

AFTER SALES SERVICE AT KEEPLEADER™

After purchasing at KEEPLEADER™ is first step of our after-service, all of machines at KEEPLEADER™ has one year guarantee, we provide free samples for defected parts to do replacement except for human damage, under information for your notice

01: KEEPLEADER™ always posts the new technical file in our homepage that can help our client in new technical information of machines’ design, character, application, operation, maintenance,

and related, KEEPLEADER™ also welcome our clients feed back the machines’ working condition that can get one to one service

02: If the machine you purchased has any defects, please contact sales representative at KEEPLEADER™, we will assign our experienced engineer analyze your case and provide technical support, in case of damaged parts that cannot repair, KEEPLEADER™ will provide a new parts to replace the defect

03: For any replacement and maintenance, KEEPLEADER™ has user manual and training video

04: KEEPLEADER™ can go to oversea for on-site training

05: KEEPLEADER™ can provide electric diagram if in need

Contact Us

KEEPLEADER, we are a professional manufacturer in the field of ultrasonic technology and other plastic joining methods,the company, which take compliance of CE certified construction, and builds a complete line of handheld plastic spot welder gun ultrasonic welding machine, likely portable,bench-top and semi-automated plastic assembly systems,which include microprocessor controlled ultrasonic welders,hot plate welder, spin frictional welder, keepleader offers in-house application assistance, materials testing service,global sales and distribution,no-site field service and the industry’s most advanced welding systems, automotive,industrial,medical packaging, toy,appliance, consumer, and synthetic textile manufacturers around the world use keepleader’s standard or customized equipment to weld the full spectrum of commodity and engineering polymers

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader