Plastic Corrugated Box Welding Ultrasonic Spot Welder of PP Corflute Board Tote_Coroplast Sheet Turnover Case Ultrasound Welders

Plastic Corrugated Box Welding Ultrasonic Spot Welder

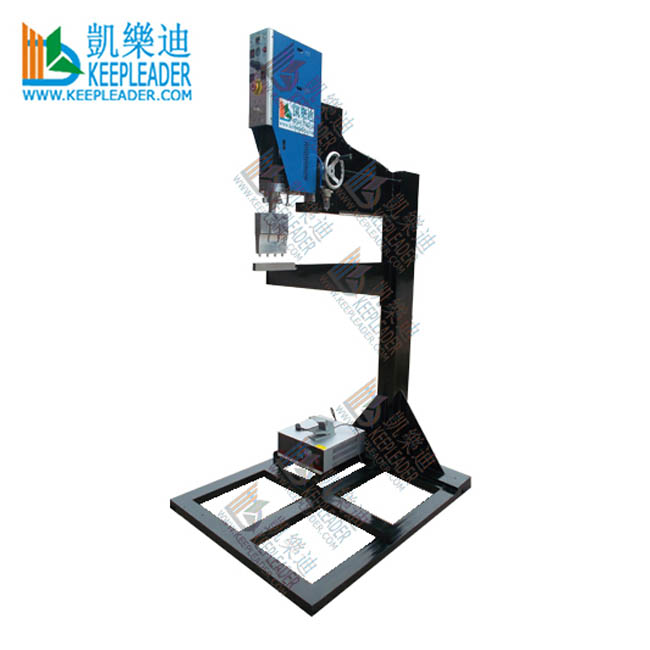

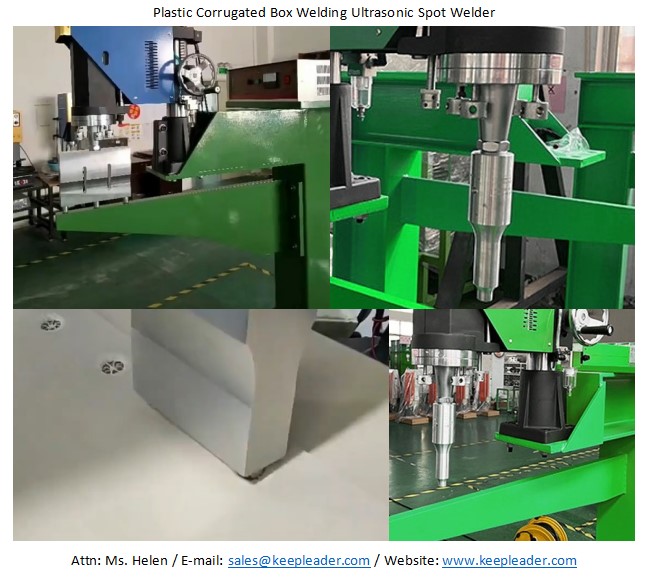

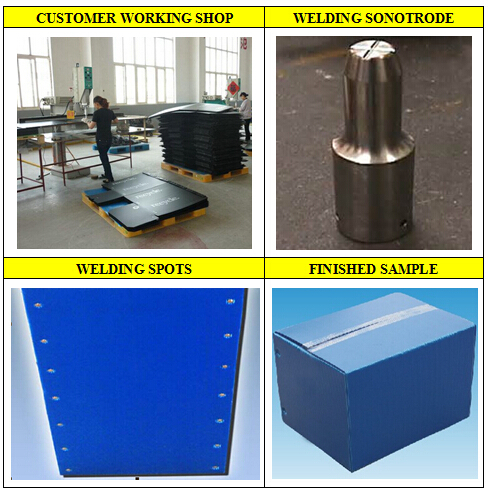

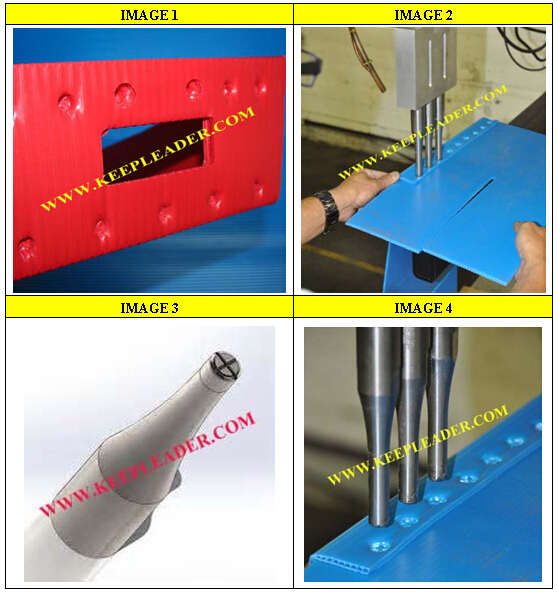

Plastic Corrugated Box Welding Ultrasonic Spot Welder integrates ultrasonic assembly with standing-along working frame with extended arm to execute spot bonding for pp totes/containers/cases making, that adopts the equal ultrasonic criteria, this free-standing ultrasonic welder transmits ultrasonic energy to the welding area through the upper ultrasonic stack, because the welding area, that is, the acoustic resistance at the interface of the two hollow boards, is large, local high temperature will be generated, in addtion, dual to the pool thermal productivity of the polypropylene,the raised temperature cannot be distributed in time for a while, and it gather in the bonding joints, causing the laminated surface of the two PP sheets to melt rapidly at the penetrated points, and after a certain pressure is applied, the are instantaneous agglutinated and merged into one, when the ultrasonic vibration stops, let the axial loading pressure continue for a while to the hold the pressure to make it solidify and shape, so that a lid molecular chain is formed to achieve the purpose of spot welding, and the welding strength can be close to the matrix material,according to the welding area of different thickness of corflute board,Plastic Corrugated Box Welding Ultrasonic Spot Welder can design single welding points, or multiple points in a mold for versatile preference,that also accept one head welding or multiple welding heads as specification

Product description

PP Corrugated Boxes Ultrasonic Welding Machine | |||

Character | |||

IC circuit precision control, automatic overload protection system | |||

Parameter | |||

Model | KLC-1020L | KLC-1520L | KLC-2020L |

Input power | 1000w | 1500W | 2000W |

Frequency | 20KHZ | ||

Input voltage | 110V/220V | ||

active horn | 70mm | ||

Oscillation system | Atuo-stimulating | ||

Output time | 0.01-99S | ||

Pressure | Pressure bound 1-7bar | ||

Welding area | 100mm | 150mm | 1800mm |

Compressor | 1HP | ||

Net weight | 100kg | 110kg | 120kg |

MFR: KEEPLEADER™ have modified and designed Plastic Corrugated Box Welding Ultrasonic Spot Welder for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Detailed Images

Plastic Corrugated Box Welding Ultrasonic Spot Welder is composed assembly of a frame and an standard ultrasonic system, ultrasonic vibration power adopts 15khz,20khz of 2kw or 2600w,the frame has extended arm of 1.2meters to produce deep loading throat, so that the versatility is stronger, and the PP corrugated box of versatile sizes are available,greatly improve the efficiency of the operator and save the time and cost,the ultrasonic process can be arbitrarily large and small on the solder joint, but the welding joint and configuration should be evaluated according to the thickness of the hollow plate,likely single point, or multi points arranged in a cycle stroke, maximum melting depth, adjustable loading depth maximum power engaged,tipped resistance during axial loading pressure

Product uses

Plastic Corrugated Box Welding Ultrasonic Spot Welder takes different types for flexible operation, they are handheld ultrasonic spot welder, standing-along pneumatic activated single head ultrasonic spot welder and standing-along,multiple heads ultrasonic spot welder, all of them have interchangeable ultrasonic acoustic tool for versatile shapes, sizes and patterns,the competed PP Corrugated boxes attains performance of no scratch,no rejection of packed items, no corrosion of joints,low running cost and better aesthetic appearance

FAQ

How can I buy good quality Plastic spin welding gun machine

Firstly: with on line or email conversation, to check the supplier is professional or not, if the supplier has ever supplied the similar machines to other buyer, will be better, don’t save time on studying, don’t stop asking questions before order, more time and efforts you spend, more you can get on the purchasing

What is the auxiliary equipment for Plastic spin welding gun machine?

It need one air compressor and necessary tooling, KEEPLEADER ™ can also make the tooling according to your welding products, the buyer need to provide samples and 3D drawing

I never use Plastic spin welding gun machine before, how can I operate it?

For small machine, under 10kw, it is easy, KEEPLEADER ™ will provide user manual and train video, also have on line service to resolve any problem

For big machine, example: 50~100kw, Engineers of KEEPLEADER ™ will come to your country, help to install the machine, and train your workers. Buyer also can come to China 1~2 days for necessary Factory training before shipment

Does KEEPLEADER also makes the tooling?

Yes, KEEPLEADER ™ has tooling department, can do customized, please provide samples and 3D drawing of igs format after order

What information does buyer need to provide in advance?

Please let KEEPLEADER ™ know, 1: material, 2: thickness, 3: size of your products, 4: sample picture, 5: purchasing budget

Does KEEPLEADER has messenger for on line service

Skype: keepleader

Whatsapp:+86 13590415784

How long is the warranty time?

One year

Contact Us

Plastic Corrugated Box Welding Ultrasonic Spot Welder is particularly developed by keepleader for manufacturing the PP Hollow board boxes, this standing-along ultrasonic spot welder can weld single points, or multiples welding points in one mold, keepleader, we can construct frame assembly as per customers’ specification, like multiple actuated heads, either or maneuverable single head, and new frame developed by keepleader is very robust and user friendly, ultrasonic system used in this standing-along ultrasonic spot welder has already proven, all components used in these spot welder are international class, we can arrange trial welding to clarify your concerns after your initiated enquiry

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader