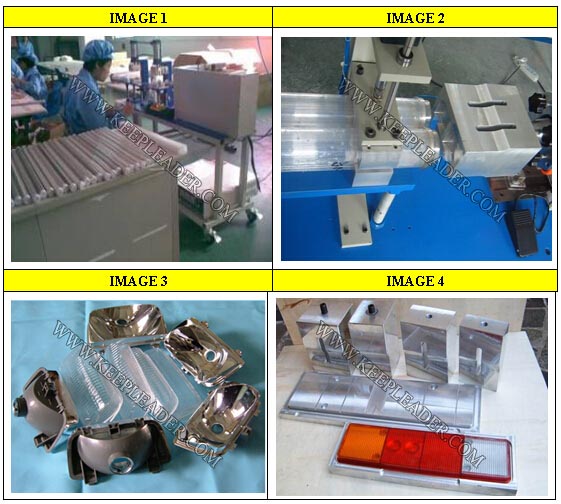

LED Guardrail Tube Welding Ultrasonic Welder of Horizontal Ultrasound Bonding Equipment for Lamp Pipe Plug Sonic Sealing Device

LED Guardrail Tube Welding Ultrasonic Welder

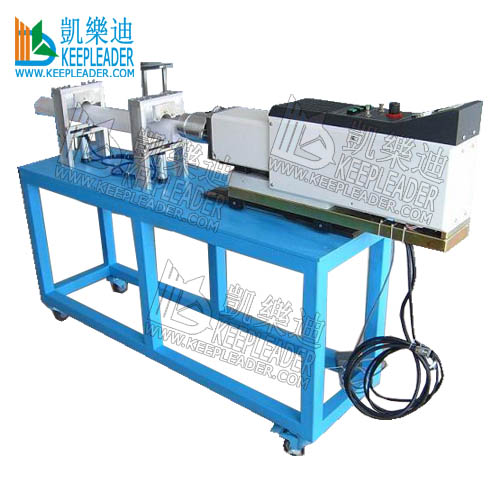

LED Guardrail Tube Welding Ultrasonic Welder construct tailored bench in assembling ultrasonic device for applying horizontal pressure in bonding pipe lamp plug, which is reliable and affordable welding system to the manufacturer of LED Tubes from lighting industry, ultrasonic generator, ultrasonic converter and ultrasonic horn, sonotrode creates the ultrasonic welding and ultrasonic sealing system, according to the led tube dimensions, the sonotrode design can be changed, LED tubes can be make of ABS,PP, ultrasonic frictional welding can exert hermetic sealing for these materials, KEEPLEADER focuses supplying long-term operating ultrasonic welding system without stopping the running production

Product description

LED Guardrail Tube Welding Ultrasonic Welder

Principle of LED guardrail tube ultrasonic welding machine | |||

The basic principle and characteristics of Plastic Guardrail tube sealing machine, LED guardrail tube welding machine, parapet light welding equipment, guardrail tube double-head sealing and welding machine: 20KHZ produced by ultrasonic generator voltage, frequency of the signal, through the piezoelectric transducers with frequency conversion into reverse effect of mechanical vibration. The basic principle and characteristics of Plastic Guardrail tube sealing machine, LED guardrail tube welding machine, parapet light welding equipment, guardrail tube double-head sealing and welding machine also has audio wave forms in the plastic products, through the surface of work piece and internal friction between the molecules that transfer to interface temperature, when the temperature reached work piece itself melting point, the work piece, then rapidly melting interface to fill the gap between interface, while shaking stops at the same time, the work piece under the pressure of certain cooling shapes, reach perfect welding. KEEPLEADER will offer one-year free technical support and services, we also offer lifelong maintenance service | |||

Application | |||

Plastic Guardrail tube sealing machine, LED guardrail tube welding machine, for O, D, U-type fence tube plug seal welding, without adhesive bonding, to the extent watertight and pleasing in appearance, easy to use. Production of high efficiency, non-performing rate is low | |||

Features | |||

Ultrasonic plastic welder using the Switzerland original transducer, titanium amplitude transformer, the output power is large and stable, solid and durable. Smart aircraft design, linear guide device from Japan, four-point level of design for chassis, it's convenient to operate. The Switzerland high-quality automatic vibration constant balanced circuit, automatic frequency tracking function. Adopt Japan, Matsushita human-machine interface, PLC control, the time control accuracy up to 0.001 seconds. Easy to operate. Use automatic lift limited mode, convenient adjustment and high accuracy. Using visual tuning depth control mode, cylinder, transducer three in one direct-drive, and high welding stability. this machine is especially adapt to used in SD card, memory card, SM card, U disk, mobile phones and other microelectronics work piece welding. it is also suitable for precision welding of work pieces, riveting, embossing, dots and other welding processes Ultrasonic plastic welders operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates. Frictional heat is produced so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time. The melting point of both working pieces is nearly equivalent which helps to form a uniform weld area. The welded area is usually as strong as the matrix material. | |||

Parameter | |||

Model | KLC-1020H | LC-1520H | LC-2020H |

Ultrasonic power | 1000W | 1500W | 2000W |

Welding size | 100MM | 150MM | 180MM |

Net Weight | 180KGS | 190KGS | 200KGS |

frequency | 20KHZ | ||

Cooling system | Fan cooling | ||

Vibration system | Self-stimulating | ||

Air compressor | 1HP | ||

Power supply | 110-220v/50hz/60hz | ||

Shape size | 560*360*960mm | ||

MFR: KEEPLEADER™ have modified and designed LED Guardrail Tube Welding Ultrasonic Welder for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Product uses

LED Guardrail Tube Welding Ultrasonic Welder is bespoke constructed ultrasonic welding equipment in the field of lighting industry,ultrasonic frictional welding is a high-tech technology for welding thermoplastic, lighting tube and lamp case are often made of acrylic, ABS, and PP, ultrasonic welding takes reliable and consistent hermetic sealing in guaranteeing the cosmetic appearance of boning object without any adhesive, fillers or solvent, and do not consume a lot of heat source, with the advantage of easy operation, fast welding speed, high welding strength, high production efficiency

Buying guides

Brief introduction

Ultrasonic welding is primarily used for thermoplastic joining, compared with other plastic welding techniques, plastic ultrasonic welding has the advantages of excellent welding quality, high production efficiency and wide application, the advantage of excellent welding are extensive and are found in many industries inclucing electronic and electrical, automatic and aerospace, civil engineering, medical and packaging field

KEEPLEADER™ can develop kinds of automatic ultrasonic welding production line to meet customers’ unique requirements, standard ultrasonic welding machine can be divided into table-type and cabinet-type, for cabinet-type, a delicate plastic welder to facilitate operation

Characters of ultrasonic welding machine at KEEPLEADER™

01: Suitable for welding, PP, PS, PE, PC, ABS, PBT and etc

02: No need any adhesive or flux and less heat consumption

03: Easy operation, high efficiency, excellent outward appearance, and high strength

04: AIRTAC pneumatic components durability

05: Automatic and manual operating mode, convenient for adjusting

06: CE, SGS international quality certificate

07: One year warranty

After-sale service

After purchasing at KEEPLEADER™ is first step of our after-service, all of machines at KEEPLEADER™ has one year guarantee, we provide free samples for defected parts to do replacement except for human damage, under information for your notice

01: KEEPLEADER™ always posts the new technical file in our homepage that can help our client in new technical information of machines’ design, character, application, operation, maintenance,

and related, KEEPLEADER™ also welcome our clients feed back the machines’ working condition that can get one to one service

02: If the machine you purchased has any defects, please contact sales representative at KEEPLEADER™, we will assign our experienced engineer analyze your case and provide technical support, in case of damaged parts that cannot repair, KEEPLEADER™ will provide a new parts to replace the defect

03: For any replacement and maintenance, KEEPLEADER™ has user manual and training video

04: KEEPLEADER™ can go to oversea for on-site training

05: KEEPLEADER™ can provide electric diagram if in need

Contact Us

LED Guardrail Tube Welding Ultrasonic Welder is one of customized ultrasonic welder with horizontal installation of ultrasonic system onto a specified length bench, the user has option of one set or sets of ultrasonic system for lighting tub plug sealing, if the user has other consideration in function and configuration, just let our sales representatives know the details for tech verification prior to order, believe that our tech team can work out a reliable and affordable solution for your production

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader