Orienting Spin Welder Plastic Welding Machine of Angular Orientation_Servo Driven Rotating Friction Circular_Round PP_PE Welders

Orienting Spin Welder Plastic Welding Machine

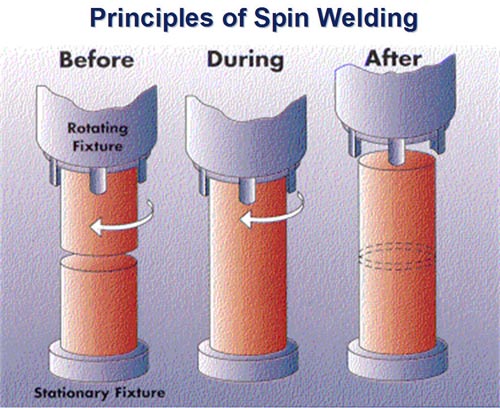

The process of Orienting Spin Welder Plastic Welding Machine consist of generating heat by rotational spin friction to weld thermoplastic parts with circular joints, the plastic spin welding machine applies force axially while rotating one part against its stationary mate, the resulting friction generate heat that melts the parts at the spherical interface, once rotation stops, the material cools and solidifies, forming a welded assembly, for cases where the parts must be oriented in a particular manner with respect to each other, the Orienting Spin Welder Plastic Welding Machine stops the rotation at a precise angular orientation

Product description

Advantage | |||

Orienting Spin Welder Plastic Welding Machine include high quality permanent joints, hermetic seals, lower equipments costs, ease of assembly, energy efficient operation, no ventilation required, immediate handling, entrapment of other parts, far-field welding capability and no additional material requirements | |||

Introduction | |||

Orienting Spin Welder Plastic Welding Machine is a type of frictional welding technology with a circular-axis joint for thermoplastic which is capable for high jointing strength and air-tightness, during spin melting, two plastic parts halves are held by two jigs, one of which is stationary while the other one is rotating in high speed against it under pressure, typically, the rotation speed is 300-1600RPM, the friction by rotation results in heating and melting spin welding area, when melting is ready, rotating jig stops and keep pressing two plastic halves together under pressure to fuse until the molten material re-solidified The rotation motion can be controlled by electrical motor or pneumatic motor, to meet the co-positioning between two plastic parts halves, spin melting welder can be departed into orientation spin melting welder and non-orientation spin melting welder | |||

Technical parameters | |||

Model | KLP-D30 | KLP-D40 | KLP-D70 |

Power output | 300w | 450w | 750w |

Power supply | AC380V/50HZ or 220v/60hz | ||

Max rotary speed | 300RPM | ||

Rated torque | 18.6n-m | 28.4n-m | 48n-m |

Max Diameter | 100mm | ||

Dimension | 780*680*2000mm | ||

Net weight | 320kgs | 340kgs | 360kgs |

Character | |||

With PLC, Convenient to set and read the data Famous brand Servo-motor for precision orientation All in one machine, is movable and save room Melting depth, rotary speed, time, torque are optional Servo-motor driven can control the melting depth, and orientation | |||

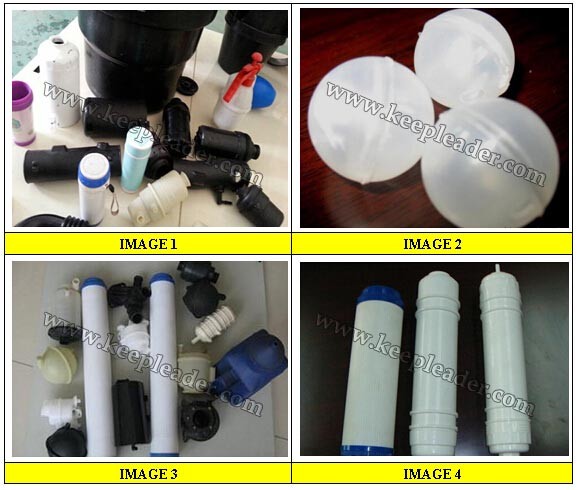

Detailed Image

Advantages of the Orienting Spin Welder Plastic Welding Machine includes assembling geometry orientation,high quality permanent joints, hermetic seal,low equipment cost compared to other processes, ease of assembly, energy efficient operation, immediate handling, entrapment of other parts, far-field welding capability and elimination of additional material, such as adhesive,bolts and other consumption

Product uses

For Orienting Spin Welder Plastic Welding Machine,In selection of motor’s power and dominant limit of torque govern joint design with primary factors, such as what type of material is to be welded; what is the overall part size and configuration; what are the ultimate stipulation of the assembling parts; is a structural bond desired;and if so, what load forces it need to resist;Is a hermetic seal required; if so, to what pressure; Does the assembly require a visually attractive appearance; Is flash or particulate objectionable inside and or outside; Does turning direction required;Does demand auto indexing;and, Any other requirements

Technology guides

01: MATERIAL CONSIDERATIONS

Material is that can be friction (i.e: vibration )welded can also be joined with by spin melting welder, the semicrystalline thermoplastics are more readily joined using spin melting welder that ultrasonic welding, using compatible polymers, spin melting welder is capable of making reliable hermetic seals, for-field welding is easier with spin melting welder that with ultrasonic welding, additional parts can be entrapped between the upper and lower pieces during spin melting weld

Joining of dissimilar polymers is possible using the spin melting welder process although it generally produces lower stretch weld joints, by design the weld joint with an undercut, the polyer with the lower melting temperature will flow into the undercut, creating a mechanical union

Material filler and surface contaminant (e.g. mold release agent) are two factors that will affect consistency and weld repeatability, spin melting welder is more tolerant of contaminants that ultrasonic welding, spin melting welder is also less effected by hygroscopic polymers, although they many still require special handing for critical application, the moisture content can lead to bubble formation in the joint resulting in decreased weld stretch

02: Joint design consideration

021: Part Joint must be on a circular axis

022: Joint design should allow for adequate collapse distance

023: Final orientation of part if necessary

024: If at all possible the upper part would be designed for use with drive features, place for upper tool to grasp the welding parts half

025: The joint area must ne designed so that there is no other part contact interference

KEEPLEADER intelligent assemble solutions offers no charge feasibility study and joint design review of your assembly

03: CONTROL PARAMETERS

There are several primary process control parameters that affect weld quality, there are the surface velocity of the weld joint, press (axial ) speed, weld depth, and hold distance time

04: SURFACE SPEED

For a fixed rotational spin speed (RPM), linear surface speed increases with weld joint diameter, for a fixed weld joint diameter, surface speed increases with motor RPM, smaller diameter parts therefore usually require more FRM that larger parts of the same material, if the surface speed is too low, an adequate amount of head will not be generated to cause sufficient melting, if the speed is too high, excessive heat in the joint could result in material degradation or reduction in viscosity leading to material flow away from the joint

The selection of proper surface speed depends to a larger degree on the material and joint geometry of the parts being welded, some materials, such as PVC, can be readily welded for a wide range of values, while others require a narrow range, commonly quoted values in the literature recommend using

05: PRESS (AXIAL) SPEED

The press speed affects the amount of contact pressure between the parts being welded, which is required to generates frictional heat, the larger the speed. The larger the rate of heat rise, in combination with the surface speed press speed must be high enough to cause melting at the interface as opposed to grinding, but not too high as to damage the parts, excessive press speed can also lead to stalling of the spin motor as more torque is required to maintain constant spin speed

06: WELDING DEPTH

The determination of the proper welding depth is highly dependent on the application, the weld joint is typically designed for a specific weld penetration, ideally, the weld is sufficiently deep to produce a strong hermetically sealed assembly, an excessive depth many lead to the formation of flash (material that is ejected from the joint area during the weld and adheres to the assembly), the drawing out of reinforcing filler material and realignment of the interchain bonds in the weld plane resulting in a weak axial weld joint. And possibly part distortion

Since weld depth affects the joint strength and amount of flash generated, it is important to design the weld joint properly to meet both requirements simultaneously, the incorporation of flash trap features is recommended to produce acceptable appearance without compromising strength

07: HOLD

During the hold phase, vertical press travel initially brings the molten parts closer together (dynamic hold) and then allows the molten material to solidify (static hold), amorphous plastics will normally take longer to solidify that semicrystalline plastic, the dynamic hold distance is typically a small value compare the weld distance, an approximate staring point for initial application setup is 10% of weld distance, the static hold can vary depending on the size of parts, but is usually in the 1-3 seconds range

Orienting Spin Welder Plastic Welding Machine usually takes 5 steps in frictional welding assembly, step1: the two thermoplastic parts to be welded are loaded into the machine, typically one into the spin tool, and the other into a stationary supportive nest called fixture; step2: After a cycle is initiated, the spin tool descends toward the fixture while simultaneously accelerating to the programmed weld spin speed,Viz: RPM;step3: after the parts come into contact each others, the tool continues to spin at a constant speed while the press forces the parts together, causing the interface to melt in frictional spin, the spinning stops once the programmed condition for ending the weld is met, such as reaching the programmed part collapse distance,Viz overlap distance;step 4:once spinning stops, the hold phase follows, typically consisting of dynamic hold and static hold, during dynamic hod, the process is advanced to further collapse the part while the plastic material is still molten,during static hold, the press position is maintained while cools and solidifies;step 5: the spin tool retracts,the two plastic halves are now joined as if molded together and are eliminated from the fixture as one assembly

FAQ

Q: What are the basic joint designs for Spin Welder Plastic Welding Machine?

Ans: The welding joint of Orienting Spin Welder Plastic Welding Machine should have a weld area equal to or greater that a typical wall section of the part, joints should also provide sufficient part-to-part alignment

Q: What do other considerations involve in spin welding design?

Ans: Parts joint must be on a circular axis; determine whether or not final orientation of parts is required; joint design must take into account flash/particulate produced during the process; preferably,upper part half will be designed for use with drive features,Viz areas for driver to engage part;ideal parting line will be parallel to the force applied by the driver;joint design must allow for sufficient collapse distance insufficient collapse may cause poor welding strength,viz bonding quality; material selection may have an impact on welder type, Viz orientation or inertial; part must be designed so that there is no contact between spinning part half and stationary part half

Q: Are you a dealer or manufacturer?

Ans: KEEPLEADER is a professional supplier of design, building, and marketing in plastic welding field

Q: What payment do you accept?

Ans: For first order, we accept 100% T/T before shipment, for repeated orders, we accept 50% advance, 40% before delivery, 10% after receiving

Q: Can we get sample machine?

Ans: KEEPLEADER only provide sample machine with updated design for our long-term cooperators, for first order or cooperation, KEEPLEADER can provide all of technical assistance for confirmation before ordering

Q: Can we print our own brand or logo?

Ans: Yes, KEEPLEADER accepts OEM order and customized design, configuration

Q: What certification does this machine have?

Ans: CE and RoHS

Q: Is my own forwarder available to transport the machine for me

Ans: Yes, KEEPLEADER accept nominated forwarder, or third part to arrange the shipment

Contact Us

Orienting Spin Welder Plastic Welding Machine assorts as frictional spin welder with servo drive turning orientation and pneumatic linear press for round/spherical/circular thermoplastic parts assembling of symmetrical joint interface,our knowledgeable applications team regularly provides joint design recommendations, material compatibility guidelines, detailed application feasibility reports and troubleshooting expertise,keepleader, we offer technology and plastic welding machines that is reliable,efficient and controllable, and back it up with unparalleled service and support, any initiation from tech consultation to machine’s maintenance attains our swift feedback,try to find what more we can do for your production without any hesitation

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader