PET Package Sealing Welder Ultrasonic Blister Welding Machine of Tabletop 20KHZ Ultra Sonic Welders for Plastic Packaging Sealer

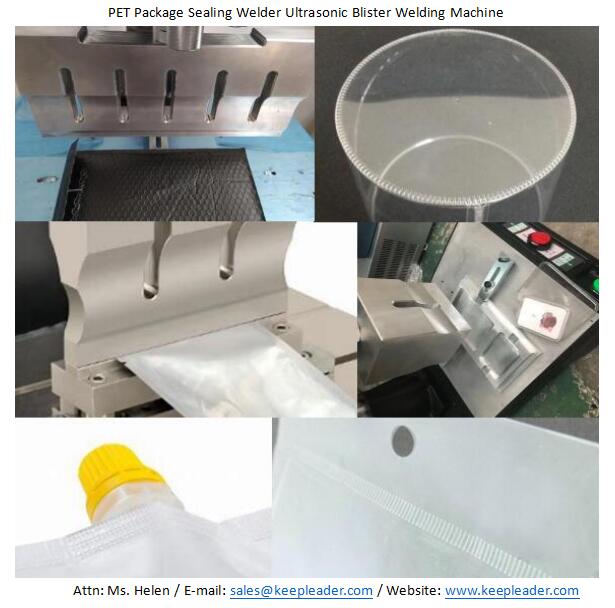

PET Package Sealing Welder Ultrasonic Blister Welding Machine

PET Package Sealing Welder Ultrasonic Blister Welding Machine qualifies for hermetic sealing in plastic packaging process,in packaging industry, PVC blister are mainly used in production line, in ordr to close the two halves of the package ends, chemical is not the right solution, the fastest and the most economical way is ultrasonic welding technology,PVC blister can be welded by high frequency welding, but PET blisters should be welded by ultrasonic vibration heating, PET material cost is nearly half of the PVC material, so for the cost effective solution,PET blisters are welded by ultrasonic welding machine, keepleader, we also provide quick-changeable tooling design in coupling with versatile production environment, portable, tabletop, or free-standing model varies from 300w to 5200w in satisfying different welding sizes

Product description

Model | KLC-3220 |

Ultrasonic power | 3200w |

Ultrasonic frequency | 20khz |

Input power | 2kw |

Welding depth | 70mm |

Welding time | 0.1~99s |

Vibration system | Auto-stimulating |

Welding size | 200mm |

Power Supply | 220V/50hz |

Net weight | 100kgs |

02: Application

Ultrasonic welding of thermoplastic materials creates a molecular bond within the welding seam, longitudinal vibrations in frequencies of 15khz, 20khz and 35khz with tool amplitudes between 5um and 50um are introduced into the plastic materials under the action of force, ultrasonic vibrations are focused by means of special design of components of tools, this specific geometry within a component is referred to as energy director, the contact points in the joining area actively molded by means of energy input to achieve elastic deformation occurring between the contact surfaces and within the molecule chains generates heat that causes the materials to melt

03: Highlighting

High efficiency converter

Rigid frame construction

Pneumatic speed regulation

Frequency tuning with reading of idling and welding power on the instrument

Triple time for delay time, welding time and holding time

Welding pressure adjustable for 6 bar

Palm button or foot operated switch operation

Microprocessor based controller

Welding time, holding time settable in the steps of 100 milliseconds

Digital counter up to 100,000 counts-resettable

Digital bar graph to indicate tuning and energy during the welding cycle

Leveling screws provided on the ultrasonic assembly for each leveling and alignment

Of horn face with the welding object

Detailed Images

PET Package Sealing Welder Ultrasonic Blister Welding Machine captures favors from seam sealing of flexible plastic packaging production,high-strength ultrasonic seals minimize leakage and prevent contamination, producing less waste and fewer rejected products, the technology eliminates consumable, allowing for smaller package size that can slash costs across the entire value china, fully compatible with recyclable and bio materials, ultrasonically welded packaging solutions provide up to 25% energy saving and cut carbon footprint up to 75%,keepleader, we stand in line with our clients around the world intending to environment-friendly, cost efficient and minimized rejection rate

Machine Uses

PET Package Sealing Welder Ultrasonic Blister Welding Machine acts as a reliable thermal bonding in plastic packaging field, such as blister/clamshell pack, aseptic, bagging, carton, corrugated plastic (mail totes,etc), cups, shrink wrap packaging, microwave/oven board,pouches, medical, spouts,strappings,tamper evident/safety caps,tubes and zip lock bags,our experienced engineers designs ultrasonic horns and fixture to cater for your versatile production

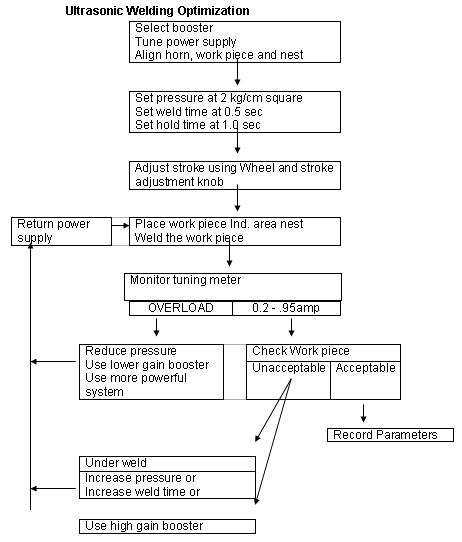

Debugging flow

PET Package Sealing Welder Ultrasonic Blister Welding Machine is easy to operate, no need special training to achieve uniform production, the only consideration aims to the ultrasonic horn, which is acoustic tool, will integrate with ultrasonic generator to take vibration heating, so, the tuning procedures of ultrasonic generate is unavoidable, particularly for new production or interchangeable ultrasonic horn assembled, yes, definitely following our guidance can yield twice the result with half the effort

Advantages

Features

01: Auto tuning

The auto tuning technology synchronize the frequency change of horn and the AMP output, the synchronization expand the auto tuning range, simplify the fabrication of the welding horn, the AMP would output the perfect vibration no matter how the temperature rises of the welding horn, that would also be able to reduce the welding failure rate, auto tuning range: 15khz to 350hz, 20khz to 700hz, 35khz to 800hz

02: Voltage feed back

KEEP the steady output of voltage and amplitude without AVR system, input voltage variation is allowed between 180v to 240v, this feedback control could guarantee the welding stability

03: Overload protect

The upper and lower specification limits of electric current and voltage can be measured, and the output can be cut out in case there is problem

04: Soft start protect

Effective soft start protect could remove the harm to the horn at the very beginning of vibration, and eliminate the malfunction at the ultrasonic vibration (tunable range: 10mses~200mses)

05: Multi-welder cylinder synchronization

Air pressure inspection and air cylinder moving speed adjustment, there two function could guarantee the synchronization of the cylinders movement when multiple welders in needed

Contact UsThere is nothing faster that keepleader’s PET Package Sealing Welder Ultrasonic Blister Welding Machine, eliminates adhesives glues, staples, clips, high frequency and thermal, no other sealing process is faster or as cost effective as ultrasonic sealing,ultrasonic is the answer for all to today’s packaging question, keepleader delivery versatile equipment and system configured to meet your packaging needs, it is helpful to come ahead of knowing your proposals upon budget,quality requested, productive environment, daily output and expected effect, please don’t hesitate to contact us with your concerns for our possible resolution

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader