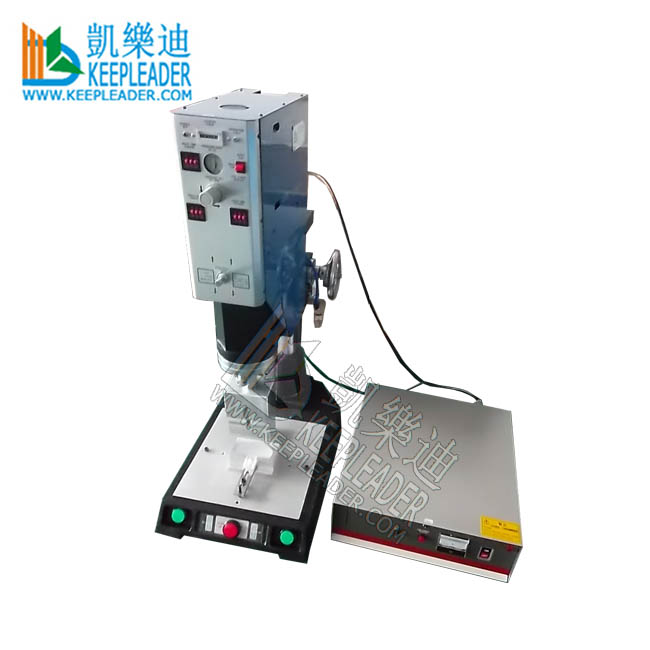

PP Filter Float Welder Supersonic Plastic Welding Machine of 15khz Ultrasonic Welders for PE_PS_PVC_PA_PC Joint Bonding Equipments

PP Filter Float Welder Supersonic Plastic Welding Machine

PP Filter Float Welder Supersonic Plastic Welding Machine is the joining or reforming of the thermoplastic trough the use of head generated from high frequency mechanical motion, it is accomplished by converting high frequency electrical energy into high frequency mechanical motion, that mechanical motion, along the applied force, creates frictional heat at the plastic components’ mating surface/joint area, so the plastic material melts and forms a molecular bond between parts, for filter cup assembling, the welding effect results in water-proof and air-tight, robust solid connecting force is even stronger that its matrix itself with perfect cosmetic appearance

Product description

Characters | |||

quick-acting clamp design for easy position in loading Capable for various shape toner cartridges welding in different sizes IC circuit precision control, automatic overload protection system | |||

Mainly parameter | |||

Model | KLC-2615 | KLC-3215 | KLC-4215 |

Input power | 2600w | 3200W | 4200W |

Frequency | 20KHZ | ||

Input voltage | 220V | ||

Max input power | 1.2KW | 1.9KW | 2.3KW |

Active horn | 70mm | ||

Oscillation system | Auto-stimulating | ||

Output time | 0.01-99S | ||

Pressure | Pressure bound 1-7bar | ||

Welding area | 200mm | 220mm | 250mm |

Compressor | 1HP | ||

Net weight | 110kg | 100kg | 115kg |

PP Filter Float Welder Supersonic Plastic Welding Machine has salient advantages of #1: fast circle times #2: very accurate #3: highly repeatable, excellent for high volumes and automation #4: environmentally safe #5: versatile well suited for various applications #6: no consumables

Product uses

What is ultrasonic welding?

01: View ultrasonic welding products

Ultrasonic plastic welding is the jointing or reforming of thermoplastics through the use of heat generated from high-frequency mechanical motion, it is accomplished by converting high-frequency electrical energy into high-frequency mechanical motion, that mechanical motion, along with applied force, creates frictional heat at the plastic components mating surface (joint area) so the plastic material will melt and form a molecular bond between the parts

02: Principle

The ultrasonic generator converts high frequency energy with be transferred to mechanical motion of same frequency through ultrasonic transducer, and then the mechanical motion can be transferred to the welding horn by amplitude modulator, which can adjust the amplitude, the welding horn will pass the absorbed heat to the junction of work pieces for welding, in this particular zone, vibration energy can be converted into the heat through friction, ultrasonic can not only be used to weld hard thermoplastic but also to process the textile and thin-film

03: Ultrasonic welding technique

031: Welding

The typical profile of a joint design for ultrasonic welding has two functions

Its shape of a groove and tongue eases positioning during assembly and maintains, in place the parts during the welding cycle

The energy director in the joint concentrates the energy to a small area supplies at the same time the necessary material for an optional welding joint, the profile of the joint area depends largely on the purpose of the application, it can therefore be shape quite differently, the settings of the machine, like welding pressure and amplitude, are adjusted to produce a movement of horn front in phase with the part to be welded, the second part placed in the fixture must stay passive, the motional interference produces friction in the contact area of the two parts, due to this highly intensive ultrasonic vibration the joint area melts together immediately, under the pressure applied simultaneously and some friction of a second longer that the ultrasonic impulse lasts the melted area solidifies and inseparable joint is produced

032: Riveting

Ultrasonic riveting is used to assemble injected plastic parts of another material, studs on the molded plastic part penetrate the second article to be mounted, the projecting part of this studs is formed into riveting heads with a specially shaped horn tip, the cavity in the horn is big enough to hold the displaced material and form it nicely, the amplitude of the horn is big enough to hold the displaced for maximum motional interference between the horn tip and plastic stud, heat is then produced by friction between the horn tip and plastic stud, heat is then produced by friction between the plastic part and the horn tip, which allows an immediate melting in this area, the pressure controlled by the welding machine lets the riveting head solidify after a short hold time, multi-tip horns are often used for simultaneous of different areas on the same part

033: Embedding

A metal piece such as a threaded insert or bolt has to be embedded into an existing hole in a plastic part, the metal piece is contacted by the oscillation horn, which creates friction between the two parts melting the plastic material, the machine pressure displaced the new melted material into the structure on the metal part surface, once the displaced material has solidified the inserted piece remains tightly seated and resists to tension as well as torsion force

Welding effect

PP Filter Cup Welder Supersonic Plastic Welding Machine has reliable performance in thermoplastic joint bonding process in field of #1: Automatic,such as instrument panels, glove box/knee bolsters, instrument clusters, interior trim, HV/AC housings, intake manifolds, carbon canisters,electronic modules, bottles, resonators #2: Packaging: such as condiment dispensers, blister packages, juice pouches, juice/milk cartons and spouts, pantyhose packages, plastic coated paper cups, toothpaste #3: stationary and gift items: such as quilted and laminated fabrics, non woven materials, bedspreads,mattress pads, diapers, air and liquid filters, hook and loop materials #4: Engineering: such as steam irons, pump housing, vacuum cleaners sub-assemblies, dishwasher spray arms, refrigerator components #5: Electronic and electrical: such as ink-jet and toner cartridge, media storage devices,battery packs, connectors, sensors, cell phones,audio/video cassettes #6: Medical and others: such as cardiometry reservoirs,blood and gas filters, IV spikes, face masks, implantable device, insulin pumps, drug delivery system, surgical gowns

Buying guides

PP Filter Float Welder Supersonic Plastic Welding Machine

Ultrasonic plastic compatibility chart | ||||

The term plastic can be used for thermoplastic or thermo set materials, most thermo set material can not be ultrasonically bonded as they burn when heated, thermoplastics are normal categorized as amorphous or crystalline Amorphous material exhibits a random structure, they are good at transmitting the ultrasonic energy to the part that needs to be bonded, amorphous material include: ABS, polycarbonate and acrylic, crystalline material has an ordered pattern, and have well defined melting temperature Crystalline material include: Acetal, Nylon, polyester, Polyethylene and polypropylene The following grid can be used to assist with plastics suitable for ultrasonic welding E=Excellent, G=Good, F=Fair, P=Poor, No= not suitable for sonic welding | ||||

Thermoplastic | Spot weld | Staking | Inserting | Near weld |

ABS | E | E | E | E |

ABS/PC | G | G | G | G |

ABC/PVC | G | G | F | G |

Acrylic | G | F | G | G |

Acrylic multi-polymer | G | G | G | G |

Acrylic/PVC | G | G | F | G |

Acrylic-impact modified | F | F | P | F |

Amorphous polymer | Spot weld | Staking | Inserting | Near weld |

Butadiene-styrene | G | G | G | G |

Cellulosics | P | G | E | P |

Modified phenylene oxide | E | E | E | P |

Polyarylate | F | F | G | G |

Polycarbonate | G | F | G | G |

Polyetherimide | G | G | E | E |

Polystyrene | F | F | G | E |

Polystyrene, impact modified | F | F | G | G |

PVC-rigid | F | G | E | P |

PVC-flexible | P | NO | NO | P |

Sulfone polymers | F | F | G | G |

Crystalline polymers | Spot weld | Staking | Inserting | Near weld |

Acetal copolymers | F | F | G | G |

Acetal homopolymer | F | F | G | G |

Fluoropolymer | NO | NO | NO | P |

Nylon | F | F | G | G |

PC-pet | G | G | E | E |

Polyester-pbt | F | F | G | G |

Polyester-pet | F | F | G | G |

PEEK | G | G | E | E |

Polyethylene (ldpe,hdpe) | G | F | E | P |

Polyethylene (uhmw) | NO | NO | NO | NO |

Polymethylpentene | G | F | E | F |

Polyphenylene sulfide | F | P | G | G |

Polypropylene | E | E | G | F-P |

PP Filter Float Welder Supersonic Plastic Welding Machine necessitates joint design of the mating parts is critical in achieving optimum assembly results, the designs depends on factor such as the type of plastic, the part’s shape and the requirements of the weld,there are many different joint design. Each with its won advantages, there are three basic requirements in joint design of #1: uniform contact area #2: a small initial contact area #3: a means of alignment #4:melting overflow entrapped #5: air-tight and water proof consideration #6: melting rate

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader