PVC Fabric RF Welder High Frequency Welding Machine of Film Sunshade PVDF Cloth_Movie Screen_Tarpaulin Tent HF Sealing Equipment

PVC Fabric RF Welder High Frequency Welding Machine

PVC Fabric RF Welder High Frequency Welding Machine is also known as radio frequency welder or dielectric welding for seam sealing of membrane structure in flexible product fabrication, its process of fusing materials together by applying a rapidly alternating electric field, applied between two bars, in the joint area, RF welder only works with thermoplastics that have a high dielectric constant, a factor determined by the molecule’s geometry and dipole moment, when tarpaulin/canvas/textile/fabric cloth exposed to alternating current, the polymer’s dipole molecules attempt to flip around to realign themselves to the new field orientation, this high-speed relative movement causes inter-molecular friction, which creates heat, when the polymer reaches its glass transition temperature, the pressure is applied at the joint by the electrode until the flowed -liquid solidification, after this intermingled bonding in molecular scale the welds can be as strong as the original materials

Product description

PVC fabric high frequency welding machine | |

Mainly application | |

PVC Fabric RF Welder High Frequency Welding Machine Used for welding Liquid tanks, canvas, car tents, tarpaulin, air structure, sun shades, awning, truck cover, Billboard inflatable dome, awning, truck covers, car tent, sunshade, inflatable tents, tailgate, inflatable dome tent, awning, tarpaulins, covers, pool liner, sunshade and many other kinds of plastic products | |

Character | |

High Q value oscillation tube the welding length is optional, maximum length:2000*25mm for 25kw The machine is G shape, have longer throat to hold the material High sensitive anti-sparkle device NL5557 to avoid damaging the mould. High quality imported apparatus European-model high frequency vibration box, more reliable and stable in output Laser position device for precision counterpoint Have boosting roller at two side for easy feeding materail Mounted five caster with four brakes Automatic thermostat to keep the temperature at best performance in welding High precision high frequency knob for visible control Low voltage control panel for safty purpose Anodized mould and tooling for longer life-span Top amounted cylinder for vertical pressing, which is more uniform pressure Foot pedal control and button control is optional Over current protection circuit to avoid burning the oscillation tube Power ranges 4kw up to 25kw for various welding length | |

Technique specifications | |

Model | KLR-8KW-SN |

Power | 8000W |

Power supply | 220V/380V 50/60HZ |

Frequency | 27.12MHZ |

Input power | 15KVA |

Rectifier | SILICON DIODE |

Oscillation tube | 7T69RB |

Max pressure | 500kg |

Gap of electrodes | 120MM |

Moving distance of active horn | 100MM |

Size of upper electrode | 1000*25MM |

Size of down electrode | 1200*300MM |

Welding time | 0~10S Adjustable |

Net weight | 400KG |

Overall dimension | Customized |

Standard equipment:

Name | Origin | Brand |

Air driven components | Taiwan | Airtac |

AC contactor | Korean | LG |

Relay | Japan | Omron |

Electron Tube | Japan | Toshiba |

Time controller | Taiwan | CKC |

MFR: KEEPLEADER™ have modified and designed PVC Fabric RF Welder High Frequency Welding Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Our PVC Fabric RF Welder High Frequency Welding Machine takes compliance with maximum permitted levels according to EU regulations, average over six minutes, electric field strength:61V/m;magnetic field strength:0.16A/m; induced current: 100mA;contact current(not averaged):40mA

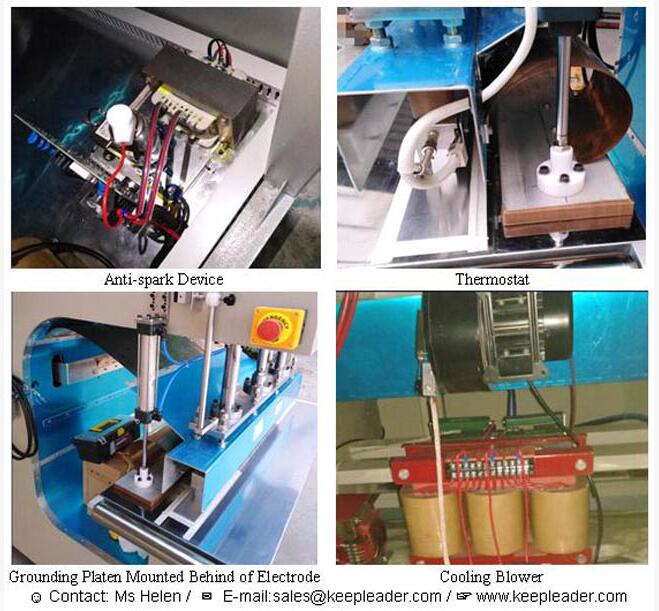

Detailed iamges

PVC Fabric RF Welder High Frequency Welding Machine acquires prominent features and benefits in plastic film seam sealing of flexible products construction, such as 1st: universal usage for PVC, PU, TUP, EVA and other reinforced technical textiles; 2nd: G shaped structure with deep material trough to go through large size alignment in welding position; 3rd: new generation stale and efficient RF power generator, reliable convert electric power to RF energy; 4th: mounting slot supports quick-changeable top electrode that comply with specified shape; 5th: laser projection of guiding beam to achieve precision alignment; 6th: convenient shift between manual, semi-automatic and automatic operation for versatile productive scenarios; 7th: safe down anti-crush electrode safety motion system; 8th: auto-tuning for steady RF power feed to assure consistent welds; 9th: RF Emission protection; 10th: tailored electrodes available for versatile production; 11th: triggering system comprises pedal valve to start welding at any direction; 12th: ultra-fast monitoring of arcs and overloads for protecting the integrity of the electrodes and welded material; 13th: for welding non-RF weldable fabric, the keepleader can be fitted with an impulse electrode

Product uses

PVC Fabric RF Welder High Frequency Welding Machine takes diverse application of PVC Welding in membrane structure, such as awnings, efficient ducting systems, prominent signs/billboards/banner/advertising cloth, durable tarpaulins and tarps, outdoor tents, projection screen, oil booms, inflatable products, canister tanks, digesting tank, secure roller door, protective soft-side curtains, resilient fabric structure and other flexible container

After sales service

PVC Fabric RF Welder High Frequency Welding Machine is a process that is used to join thermoplastic material of membrane structure, or fabric coated weldable polymer, welding completion by heating up the laminated materials from inside using radio frequency electromagnetic energy of oscillation frequency: 27.12 megahertz to fuse the two squeezing material together, this process is achieved by using an RF welding machine, the heat is created by sending radio frequency energy through layers of plastic material, the dielectric loss,Viz resistance of the molecules against oscillation creates the heat which is generated on the inside of the material not through the surface, pressure is exercised at the same time, and after weld cycle is finished, the pressure is maintained through the cooling cycle

The user can gain our following commitment

After purchasing at KEEPLEADER™ is first step of our after-service, all of machines at KEEPLEADER™ has one year guarantee, we provide free samples for defected parts to do replacement except for human damage, under information for your notice

01: KEEPLEADER™ always posts the new technical file in our homepage that can help our client in new technical information of machines’ design, character, application, operation, maintenance,

and related, KEEPLEADER™ also welcome our clients feed back the machines’ working condition that can get one to one service

02: If the machine you purchased has any defects, please contact sales representative at KEEPLEADER™, we will assign our experienced engineer analyze your case and provide technical support, in case of damaged parts that cannot repair, KEEPLEADER™ will provide a new parts to replace the defect

03: For any replacement and maintenance, KEEPLEADER™ has user manual and training video

04: KEEPLEADER™ can go to oversea for on-site training

05: KEEPLEADER™ can provide electric diagram if in need

Contact Us

KEEPLEADER, we act as a reliable manufacturer in technique field of plastic sealing over fifteen years, continue to add more, uniquely positioning us to meet the capacity and capability requirements of our most demanding customers, PVC Fabric RF Welder High Frequency Welding Machine is our standing-along RF Dielectric bar welder applied for seam sealing of membrane structure, that also can consist of automatic travelling head with specified bench and hanging head for large volume geometry construction, let’s concentrate your initiation in individual production, contact us today to gain more or verify your productive concerns, ensure that our expertise is attainable during your consultation

☺ Attn: MS Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone: +86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader