Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine of Robotic Arm Multiple Tasks Washing Ultrasound Tanks

Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine

Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine is used when more than just an ultrasonic cleaning tank is required, most customers require rinsing operation for some type (pre-cleaning or final cleaning quality) to remove the detergent used in the ultrasonic cleaning tank, others cleaning steel parts may require a rust preventative be applied to their parts, and many will require a drying operation, Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine accomplishes any or all of this tasks by providing multiple processing tanks, each with a particular function, the first tanks is usually ultrasonic cleaning tank, the second may be a rinsing tank, the third may be a rust preventative dip tank, and the forth a drying tank, any combination is available from keepleader, even, one particular process takes completion among multiple tanks to enhancing performance, baskets of parts are transferred from tank to tank to complete the entire process with robotic arm and any number of tanks can be supplied, making Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine the best choice when your parts require more than just the ultrasonic cleaning tank in medical device cleaning process

Product description

Medical Device Ultrasonic Cleaning Machine of Automatic Ultrasonic Cleaning | |

Application | |

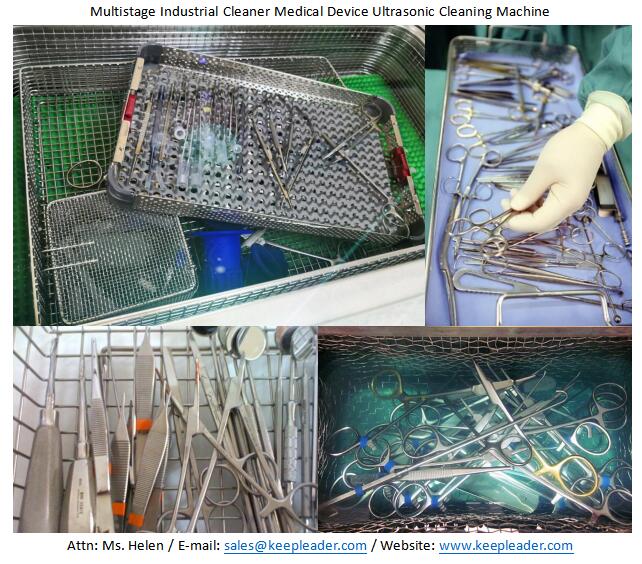

This Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine is professional designed for cleaning in medical device/medical equipment/medical apparatus and instruments and other precision plastic and metal parts, the machine is full-enclosed in the glass window, which is easy to check the process and avoid secondary pollution | |

Character | |

PLC operation panel, also equipped handheld emergency pause/stop switch The circuit designed with soft-start and over-current protection All of reachable power wire is low-voltage/within 16v Imported vibrators IIE made in USA Stainless steel cleaning tank, SUS304,2.0mm for thickness Other electronics, made in Japan or South Korea Liquid level sensor and alarm system for ensuring the machine work properly Solvent filtration and recycling system reduce the production cost Automatic temperature control system Moving blast nozzle mounted at the top for fast drying Automatic load and unload cleaning parts to reduce the labor force Pneumatic valve block to control the transfer among the working positions Interval orbit designed robot arm in transferring to improve the feeding efficiency | |

Qualified Solvent | |

Trichloroethylene, methyl chloroform and other organic solvents (non-flammable solvent) | |

Cleaning process | |

Hot water immersible cleaning→ultrasonic cleaning→rinsing with bubbling device→air drying with moving blast nozzle | |

mainly parameter | |

hot water immersible cleaning | |

internal cleaning tank | 300*320*340mm (L*W*H) |

Vibration mode | Bottom |

Vibrators number | 12pcs |

Ultrasonic power | 600w |

Ultrasonic frequency | 28khz or 40khz |

Heating power | 2kw |

Heating mode | Heating board from outside |

Temperature | 0 up 100 |

Ultrasonic cleaning | |

Internal cleaning tank | 300*320*380mm |

Ultrasonic power | 600w |

Ultrasonic frequency | 28khz or 40khz |

Heating power | 2kw |

Heating mode | Heating tube into the water |

Temperature | 0 up 110 |

Water Rinsing tank | |

Internal cleaning tank | 300*320*390mm |

Auxiliary | Bubbling device+ ultrasonic/optional |

Drying tank | |

power | 3HP |

Auxiliary | Moving blister nozzle |

General parameter | |

Overall size | 2230*1200*2170mm |

Overall power | 11kw |

Power supply | AC380V,50HZ |

Net weight | 800kgs |

MFR: KEEPLEADER™ has modified and designed Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine to accommodate our customers’ unique and special requirements, pls contact KEEPLEADER™ for tech assessment

Note:

Please tell us following information:

1. The material and definite size of the product;

2. Internal size of cleaning tank you wanted;

3. the features do you preferred

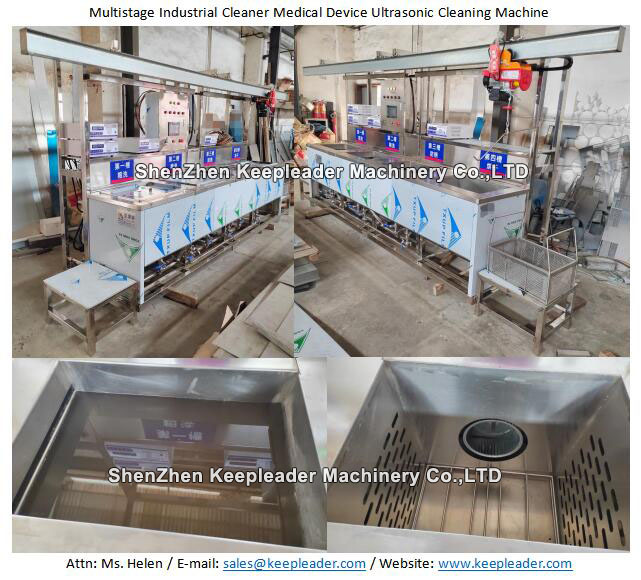

Detailed Images

Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine is designated ultrasonic cleaning machine for medical device manufacturer, that is reliable for decontamination of machining medical parts to clean very high volumes of complex parts, it includes features that ensure the most consistent results possible, even when cleaning medical device with high levels of details, internal channels and passageways and blind holes in multiple orientations, in addition, the cleaned parts can reach criteria of sterilization and disinfection, Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine gains the pioneered decontamination, its advantages are obvious, such as two positions of precision cleaning to guarantee the deepest penetration; centrifugal drying tank can apply all-directional drying process; prevents re-deposition of floating contaminants onto parts by skimming surface oils from the cleaning tank on cascading tank; cascade overflow rinse tanks for zero-residue performance; automatic rinsing water quality maintenance; provides agitation during cleaning and rinsing processes; eliminates air bubble entrapment which can prevent cleaning; rust preventative coating to prevent oxidation after cleaning process; robotic arm transmission system transfer the basket among the multiple tanks to efficient labor force and cost; programmable logic control with touch screen, that is convenient setup, operation, monitoring and maintenance in entire processes

Machine Uses

Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine provide medical device manufacturers ultrasonic cleaning solutions for their metal device or plastic consumable parts that easily integrate into virtually any medical device manufacturing process including machining, molding, polishing, electroplating, passivation and more, keepleader’s Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine adopts multiple stages to complete rough cleaning, precision cleaning, rinsing, passivating, drying in a production line, in addition, the robotic arm integrate in transferring system, that is efficient for saving cost and labor force, and the auto monitoring devices mounted are efficient factor in achieving a validated state for medical devices cleaning

Buying guides

Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine obtains gratification because of its prominent features, such as: all made of stainless steel, particularly, stainless steel tank of chrome coated is cavitation resistant with guaranteed longevity; ultrasonic decontamination and ultrasonic rinsing both integrate ultrasonic agitation for quality penetration; cascading overflow rinsing to obtain zero residue by timely remove floated oil; independent passivation immersive tank for dust resistance coating; centrifugal drying tank contains ceramic heating elements for achieve all-directional drying process; pump filtration models with liquid booster reservoir to continuously remove the contamination from the system that can avoid secondary deposition; programmable logic control with touch screen gain convenient for setup, operation, monitoring, maintenance and troubleshooting; robotic arm transmission to improve the efficiency and save the labor strength; full-enclosed or semi enclosure depends on customers’ preference

01: Choose your correct system

For customers demanding multiple stage ultrasonic cleaning and high efficiency parts drying, KEEPLEADER™ multi-stage consoles provide the same efficient, effective ultrasonic cleaning technology plus the ability to move the items items through additional wash and rise stages, KEEPLEADER™ will design a custom-sized and custom-featured ultrasonic cleaning machine to meet your specific needs

011: heated ultrasonic cleaning

012: heated ultrasonic cleaning + heated rinse

013: heated ultrasonic cleaning + heated ultrasonic rinsing

014: heated ultrasonic cleaning + heated ultrasonic rinsing + hot air drying

015: Inner size of cleaning tank, frame construction, custom color, ultrasonic frequency

02: Choose your tank size

021: the length*Width*depth you wanting

022: advise KEEPLEADER™ the size of your cleaning parts and cleaning efficiency

03: Each system includes:

031: Full insulated stainless steel tanks

032: Exterior power coat finish

033: Digital temperature controls-each tank

034: Digital timer-controlled ultrasonic cleaning

035: Dual stage filtration-cleaning stage

036: Single-stage filtration rinse stage

037: Low-level float sensors-each stage

04: Exceed industry standards

041: All size available, including bench version

042: High quality stainless steel construction

043: For vapor degreasing, cleaning and drying applications

044: Full solution control features

Contact Us

Keepleader’s Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine is the ultimate solution in the complete cleaning of any parts or assembly, typically used in medical device cleaning in manufacturer, this Multistage Industrial Cleaner Medical Device Ultrasonic Cleaning Machine combines the power of ultrasonic cleaning with pressure washing, rinsing, passivation, drying and multiple other thorough cleaning technique developed over many years of solving unique cleaning problem, in addition, robotic transmission system completes vertical and horizontal movement to save the labor force and improve the working efficiency, we can take bespoke construction with specified configuration and dimension to suit customers’ particular requirements, contact our experts for more details

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader