Flexo Printing Anilox Roller Cleaning Ultrasonic Cleaner for Steel_Ceramic Flexographic Printing Head Ultrasound Wave Degreaser

Flexo Printing Anilox Roller Cleaning Ultrasonic Cleaner

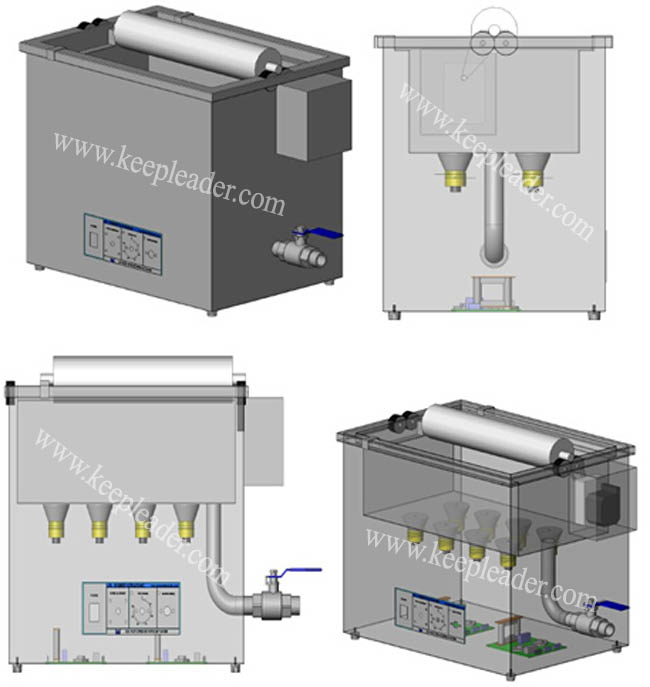

"Flexo Printing Anilox Roller Cleaning Ultrasonic Cleaner" is only used for flexo printing ceramic/steel anilox roller cleaning, the length of cleaning tank will comply with your maximum cleaing size, js ajustable for small size, one circule can hold mutiple anilox roller cleaning. the ultrasonic frequency can be 28khz, 40khz or bigger, pls tell us your preferred

Product description

Flexo Printing Anilox Roller Cleaning Ultrasonic Cleaner

Parameter

Model | KLE-10A |

Ultrasonic power | 1500~3600W |

Vibrators number | 30~72pcs |

Frequency | 28khz/40khz |

Heating power | 2kw~4kw |

Driving system | Servo motor control, chain transmission |

Inner size | L: 450~2500 W: 450~550 H: 250~300mm |

Inner tank | Stainless steel, 2mm SUS316L |

Outside housing | Stainless steel 2mm SUS304 |

Solution | Non-inflammable, water-based, alkali solution |

Power Supply | DC: 100V~240V, 50/60hz |

Dimension | L: 1850~2900 W: 550~650 H:600mm |

Net weight | 180~380kgs |

Gross weight | 220~480kgs |

Anilox roller ultrasonic cleaning machine

What’s anilox roller and how to clean it efficiently?

Cleaning the equipment and heavy duty products is a tough task that can’t be performed with simple tools. Due to the frequent use of the machine and electronic parts, deep cleaning is essential to give it proper and smooth function in every use, most of companies search for the technology, which covers the work in a easy way

Thanks to the advance developments in the field of technology and printing, that anilox rollers have gained a lot of popularity that a transfer roller. Mainly, anilox roller is a versatile tool in coating and decorative applications and right now it is being used to create prominent capacity whites and foundation coats, mainly for the stretchy packing, applying coatings, adhesives for the cold foil, coating for the images varnishes and other decorative purposes

It is a ceramic roller or an engraved metal roller mainly brought into use for the printing press to transfer the ink form the roller to the printing plate, its main purpose is to pick the ink from the roller or form any of the configurations and deliver a uniform amount of it to the robber plate for the printing process

It is mainly designed for most favorable ink release as a surface and it is laser fixed to reduce the porosity of cell wall and is strengthened by its ceramic subsurface, which benefits the printing quality, optimized cell profiles, improved consistency and more volumes of screen definition

It is mainly designed for most favorable ink release as a surface and it is laser fixed to reduce the porosity of cell wall and is strengthened by its ceramic subsurface, which benefits the printing quality, optimized cell profiles, improved consistency and more volumes of screen definition.

Used for printing task for good impression on the material

In printing task, anilox play a major role to provide the required amount of the ink to a flexo printing plate, this hard cylinder shaped roller contains millions of fine dimples referred as dells and are semi submerged in the fountain of ink to make a thick layer of it on the roll, after that, a doctor blade is applied to scrape the extra ink from the roller surface to have the measured amount of ink in the dimples

After this, the roller is rotated in contact with the printing plate on whick the ink from the cells get transferred on the material for the required impression, this provide better performance and offers cost effective solutions to the customs, after the use of this metallic roller, there is no need of any ho foil units to complete the task and face the competitive market, just select your type of roller and let it do proper work with special care

Needs proper maintenance

Due to the regular use of anilox rollers for printing work, proper maintenance is essential to give it durability and flexible use, to maintain it, ultrasonic anilox cleaner is the most efficient method to clean the anilox roller as it is a tested and proven method for cleaning most of the components which are tough to be cleaned in a normal way

The reason to use it is that, ultrasonic cleaning technique is a fast method and cleans up to 90% of the product, there is no need to let the people watch the cleaning process and handle it as it does no its own with labor saving benefits

Mainly, ultrasonic reaches to the depth of the roller and clears any residues of the ink or liquid from the holes, cervices, internal chambers, which cannot be cleaned efficiently with other device, the waves of ultrasonic go through the microscopic cell openings disturbing the cleaning liquid deep in the cavities of the cell to remove the settled and dried ink from every bottom corner of the roller to tet the best cleaning results, make use of a heated cleaning solution which is specifically formulated for the cleaning task at a certain temperature which is recommended by experts

Clean it effectively for better performance

As ultrasonic anilox roller cleaners are mainly designed for anilox rollers, proper care need to be taken to prevent any damages as ultrasonic system is specifically designed for safe and effective leaning on the metal and ceramic rollers, the ultrasonic cleaner provides a pre-determined frequency operated on its won with low voltage supply which maintains a stable distribution split from a line fluctuation which results in hot spot being shifted up and down to prevent the damage due to the concentration of the power at one point one the roller, it is quite essential to keep your anilox rollers clean to deliver more volumes of printing work which involves the interaction of multiple colors of ink as per the requirement of the customer which is must to compete in the market, it is more vital to maintain a good anilox roller which is the most effective thing to develop business and production, it is specially mentioned to use the brushes and tools which clears the minute cell in the roller in a better and safe way without damaging the sensitive parts that are most important to perform the printing work on the plate

Product overview

For "Flexo Printing Anilox Roller Cleaning Ultrasonic Cleaner", keepleader will provide modified drawing with your required size for your final confirmation before production

Product uses

For "Flexo Printing Anilox Roller Cleaning Ultrasonic Cleaner" you need to tell us the material of your anilox roller (steel or ceramic) and their length in maximum in reference of aboove illustration, and choose suitable cleaning detergent

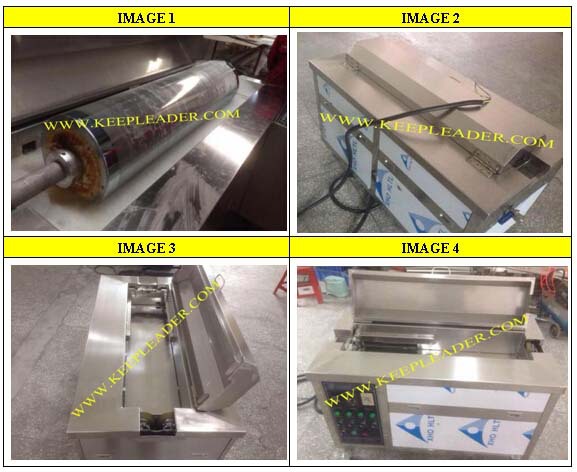

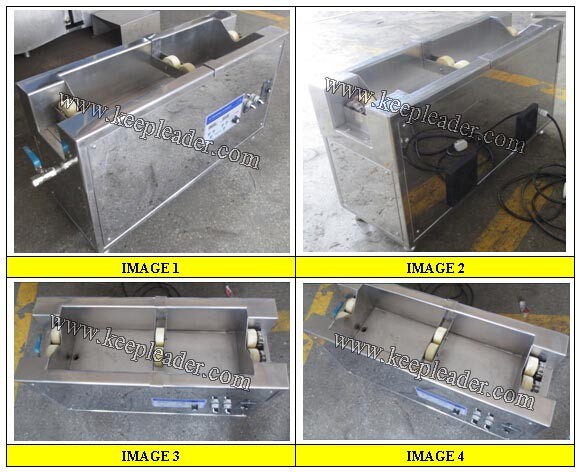

Detailed images

For "Flexo Printing Anilox Roller Cleaning Ultrasonic Cleaner" the popular model is ultrasonic generator mounted in under cabinet, keepleader also can design separated cabinet standing aside of cleaning tank

Contact Us

Ms Helen is professional lady engineer in marketing dept, for "Flexo Printing Anilox Roller Cleaning Ultrasonic Cleaner" she has even designed satisfied anilox roller cleaning machine, is reliable and valuable business partner to consuilt with

☺ Attn:Ms Helen

✉ E-mail:sales@keepleader.com

☎ Cellphone:+86 13590415784 (Wechat/Whatsapp)

☎ Tel: +86 755 84190358

☞ Website: www.hfwelds.com / www.keepleader.com

Products

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader