Tech Principle of High Frequency PVC Tarpaulin Welding Machine

High Frequency PVC Tarpaulin Welding Machine

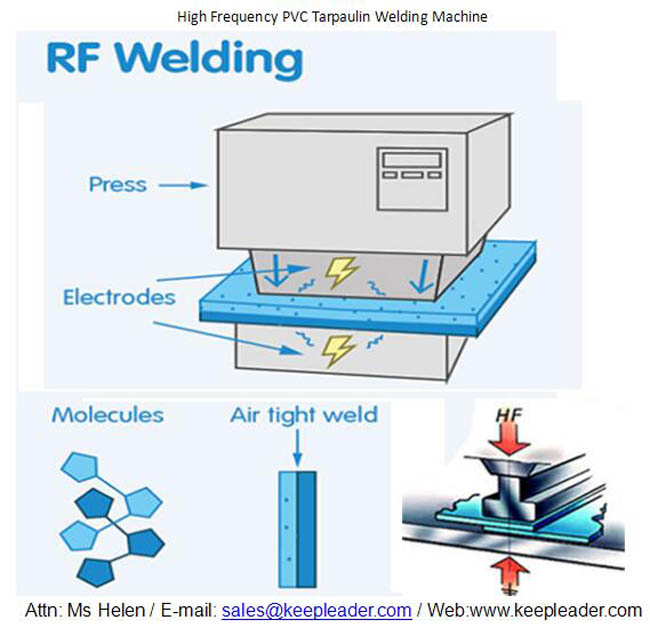

High Frequency PVC Tarpaulin Welding Machine know as radio frequency (RF) welding or dielectric welding. Is the process of fusing tarpaulin together by applying radio frequency energy to the area to be joined, the resulting weld can be as strong as the original tarpaulin. High frequency welding replies on certain properties of the tarpaulin being welded to cause the generation of heat in a rapidly alternating electric field. This means that only certain tarpaulin can be welded using this technique. The process involves subjecting the parts to be joined to a high frequency (most often 27.12MHz and 13.56MHz) electromagnetic fields, which is normally applied between two metal bars/electrodes. These electrodes also act as pressure application during heating and cooling. The dynamic electric field causes the molecules in polar thermoplastics to oscillation. Depending on their geometry and dipole moment, these molecules may translate some of this oscillatory motion into thermal energy and cause heating of the tarpaulin. A measure of this interaction is the loss factor, which is temperature and frequency dependent.

PVC and polyurethanes are the most common thermoplastics to be welded by the high frequency process, it is possible to high frequency weld other polymers including nylon, PET, PETG, APET, EVA and some ABS resins, but special conditions are required, for example nylon and PET, are weldable if preheated welding electrodes/bars are used in addition to the high frequency power.

High frequency welding is generally not suitable for PTFE, Polycarbonate, polystyrene, polyethylene or polypropylene, however, due to the impending restrictions in the use of PVC, a special grade of polyolefin has been developed which does have the capability to be high frequency welded.

The primary function of high frequency PVC tarpaulin welding is to form a joint in two or more thickness of tarpaulin, tent, PVC/PU Coated fabric. A number of optional features exist. The welding tool can be engraved or profiled to give the entire welded area a decorative appearance or it can incorporate an embossing technique to place lettering, logos or decorative effects on the welded object. By incorporating a cutting/trimming/forming edge to the welding surface, the process can simultaneously weld and trim/cut/form a tarpaulin, the forming edge compresses the hot plastic sufficiently to allow the excess scrap material to be torn off, hence this process is often referred to as tear-seal welding.

A typical plastic welder consists of a high frequency generator (which creates the radio frequency current), a pneumatic press, an electrode that transfer the radio frequency current to the material that is being welded and welding bench that holds the material in place, high frequency PVC tarpaulin welding machine is radio frequency process in membrane structure seam sealing, the machine could also have a grounding bar that is often mounted behind the electrode, which leads the current back to the machine (grounding point). there are different types of plastic welders, the most common being tarpaulin machine, packaging machine and automatic machines.

By regulating the machine’s tuning, the field strength can be adjusted to the material being welded, when welding, the machine is surrounded by a radio frequency field that, if too strong, can be heat up the body somewhat. This is what the operator needs to be protected from. The strength of the radio frequency field also depends on the type of material being used. Generally, machines with visible open electrode (non-shielded) have stronger fields than machines with enclosed

When describing high frequency electromagnetic field, the field’s frequency is often mentioned, the permitted frequency for tarpaulin welding machine is 13.56MHz, 27.12MHz or 40.68MHz, the most popular industrial frequency for high frequency tarpaulin welding machine is 27.12MHz.

The radio frequency welding (High frequency welding) fields from a plastic welding machine spread out around the machine, but most often is only right next to the machine that the field is so strong that precautions need to be taken. The field’s strength decreases sharply with distance from the source. The strength of the field is given in two different measures: the electric field strength is measured in its per metre (V/M), and the magnetic field strength is measured in amperes per metre (A/m). both of these must be measured to get an idea of how strong the radio frequency/high frequency field is. The current that goes through you if you touch the equipment (contact current) and the current that goes through the body when welding (induced current) must be measured

Maximum permitted levels according to EU regulations

Average over 6 minutes

Electric field strength: 61v/m

Magnetic field strength: 0.16A/m

Induced current: 100 mA

Contact current: (not averaged): 40mA

Search

ContactUs

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China

ZIP: 518129

Contact: Ms Wang

Tel: +86-755-84190358

Fax: +86-755-84190358

Mob: +86-13590415784

Email: sales@keepleader.com

Welcome to visit our Factory!!!

Copyright ©2004-2026 ultrasonic cleaner,ultrasonic welder,high frequency welder,Ultrasonic golf Cleaner,High frequency packing machine,Vapor degreaser,Transparent Cylinder making machine,portable spot welders All Rights Reserved.

ADD: Rongxing Bldg, Bulong rd, Bantian st, Longgang, Shenzhen 518129 P.R.China ZIP: 518129 Contact: Ms Wang

Tel: +86-755-84190358 Fax: +86-755-84190358 Mob: +86-13590415784

Email: sales@keepleader.com 技术支持: keepleader